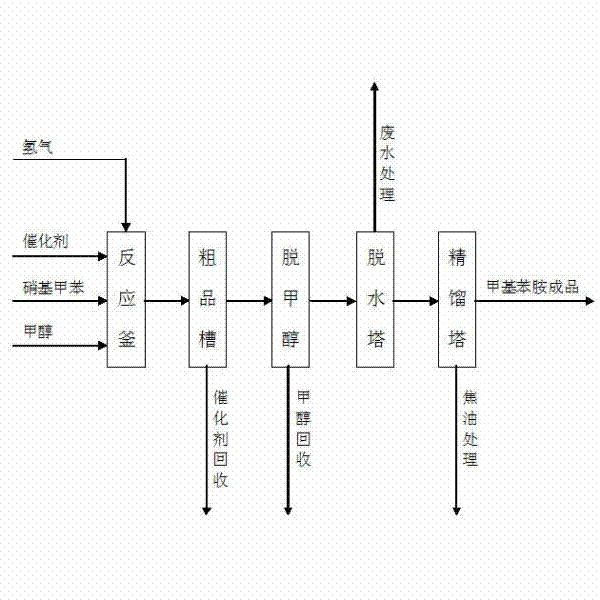

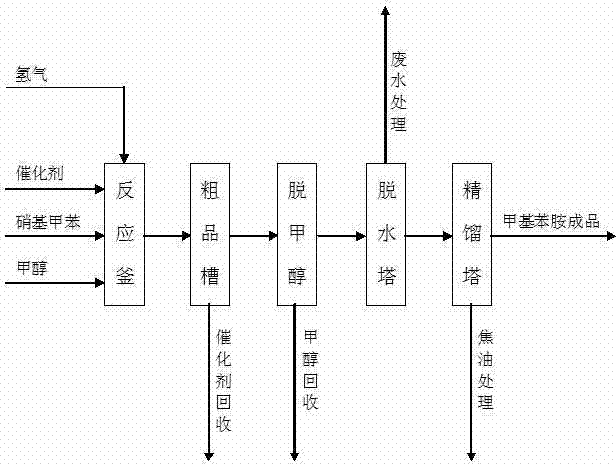

Method for producing methylaniline from nitrotoluene through liquid-phase hydrogenation reduction

A technology of nitrotoluene liquid and methylaniline, which is applied in the field of nitrotoluene liquid-phase hydrogenation reduction to produce methylaniline, can solve the problems of poor product quality, low yield, short storage time, etc., and is easy to achieve Operation management, high yield and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: through pipeline to volume is 5m 3 In the reaction kettle, add 2000Kg of methanol as a solvent, and at the same time add the expanded Raney nickel catalyst through the pipeline, add 40Kg when starting up for the first time, and only need to add 2Kg to each kettle when it is in normal production. Adjust the outlet pressure of the machine to 1.0MPa to completely replace the air in the reactor, start the stirring motor, control the rotation speed to 320r.p.m to raise the temperature, and when the temperature of the reactor is heated to 55°C, use a metering pump to pass the purity test through the pipeline. Gradually add 2000Kg m-nitrotoluene with not less than 99% into the kettle to start the reaction; turn off the heating steam, open the cooling water valve, and control the temperature at 80-90°C. After 3-4 hours of reaction, when the pressure of the reactor rises, the temperature When it stops rising, it means that the reaction has basically ended; at this ...

Embodiment 2

[0014] Embodiment 2: through pipeline to volume is 5m 3 In the reactor, add 2000Kg of solvent methanol, and at the same time add the Raney nickel catalyst through the pipeline, add 45Kg when starting up for the first time, and only need to add 2Kg to each kettle when it is in normal production, feed hydrogen through the pipeline, and pressurize the hydrogen Adjust the outlet pressure of the machine to 1.1MPa to completely replace the air in the reactor, start the stirring motor, control the rotation speed to 330r.p.m, and raise the temperature. When the temperature of the reactor is heated to 55°C, use a metering pump to pass the purity test through the pipeline. Gradually add 2000Kg p-nitrotoluene with not less than 99% into the kettle to start the reaction; turn off the heating steam, open the cooling water valve, and control the temperature at 80-90°C. After 3-4 hours of reaction, when the pressure of the reactor rises, the temperature When it stops rising, it means that th...

Embodiment 3

[0015] Embodiment 3: through pipeline to volume is 5m 3 In the reactor, add 2000Kg of methanol as a solvent, and at the same time add the expanded Raney nickel catalyst through the pipeline. When starting up for the first time, add 50Kg. When it is in normal production, you only need to add 2Kg to each kettle. Adjust the outlet pressure of the machine to 1.2MPa, after completely replacing the air in the reactor, start the stirring motor and control its speed to 345r.p.m to raise the temperature. When the temperature of the reactor is heated to 55°C, use a metering pump to pass the inspection through the pipeline. 2000Kg o-nitrotoluene with a purity of not less than 99% is gradually added to the kettle to start the reaction; turn off the heating steam, open the cooling water valve, and control the temperature at 80-90°C. After 3-4 hours of reaction, when the pressure of the reactor rises, When the temperature no longer rises, it indicates that the reaction has basically ended; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com