Supported non-metallocene catalyst, preparation method and application thereof

A non-metallocene, supported technology, applied in the field of non-metallocene catalysts, can solve the problems of low olefin polymerization activity, limited intrinsic properties of non-metallocene complexes, and difficulty in controlling the shape of catalyst particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

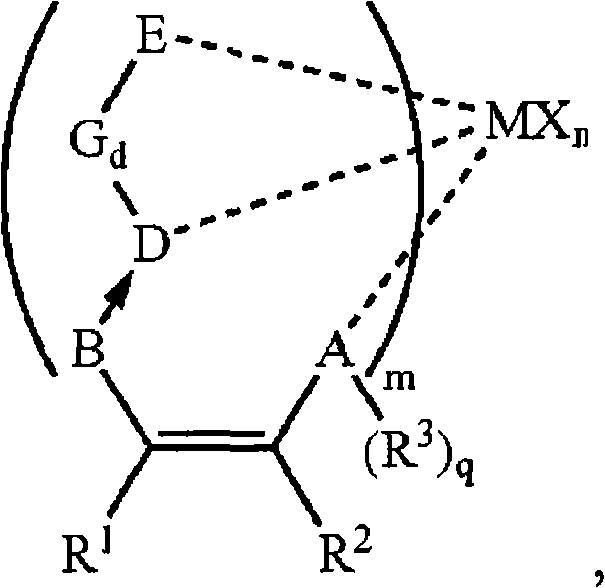

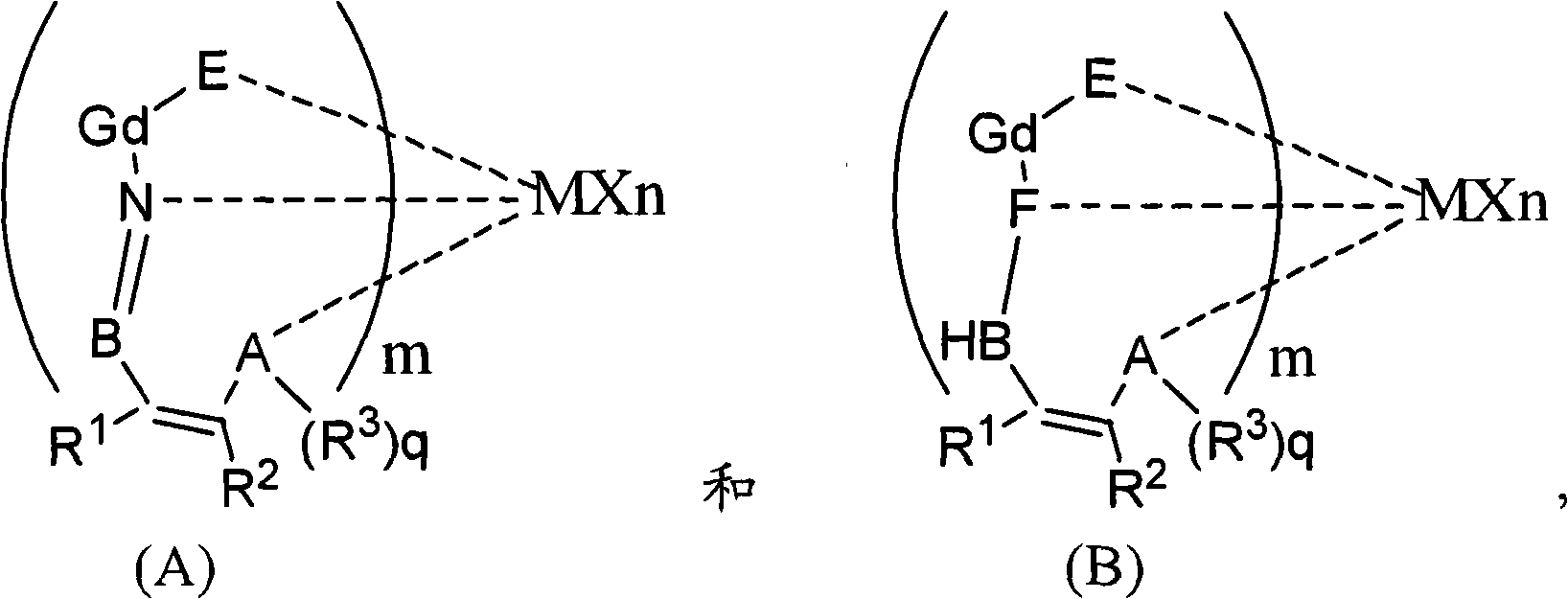

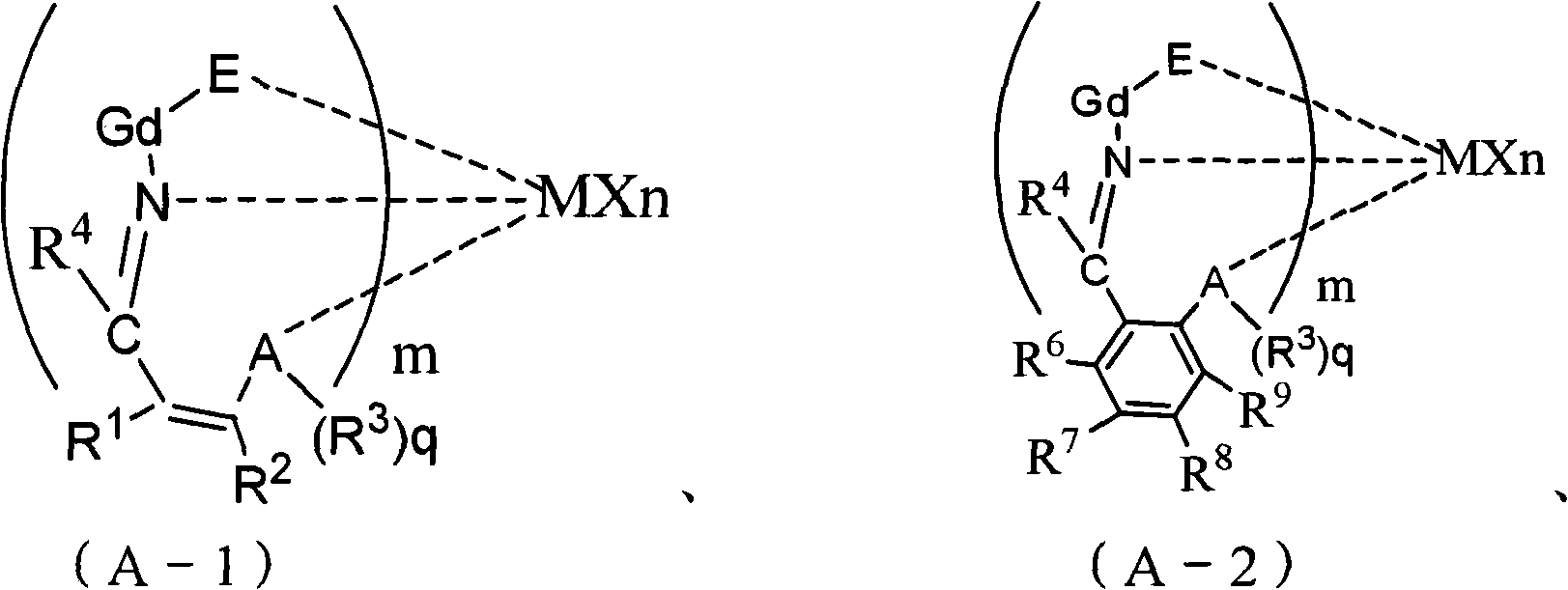

[0094] The present invention relates to a method for preparing a supported non-metallocene catalyst, which includes the following steps: reacting a chemical treatment agent selected from group IVB metal compounds with a porous support optionally undergoing thermal activation treatment to obtain a modified support; The step of dissolving the compound in the solvent to obtain a magnesium compound solution; the step of contacting the modified carrier, the magnesium compound solution and the non-metallocene complex to obtain a mixed slurry; adding a precipitant to the mixed slurry to obtain a composite The step of supporting; and the step of reacting a chemical treatment agent selected from the group IVB metal compound with the composite support to obtain the supported non-metallocene catalyst.

[0095] The porous carrier will be specifically described below.

[0096] According to the present invention, as the porous support, for example, those organic or inorganic porous solids conven...

Embodiment 1

[0322] The porous carrier uses silica, namely silica gel, the model is ES757 of Ineos Company. First, the silica gel is calcined at 600° C. under a nitrogen atmosphere for 4 hours to thermally activate.

[0323] The chemical treatment agent uses titanium tetrachloride (TiCl 4 ). Weigh 5g of thermally activated silica gel, add 60ml of hexane, add titanium tetrachloride under stirring at room temperature, after reacting at 60℃ for 2h, filter, wash with hexane 3 times, 60ml each time, and finally vacuum dry to obtain Modified vector.

[0324] The magnesium compound is anhydrous magnesium chloride, and the solvent for dissolving the magnesium compound and the non-metallocene complex is tetrahydrofuran. The structure of the non-metallocene complex is compound of.

[0325] Weigh the anhydrous magnesium chloride and non-metallocene complex, add tetrahydrofuran solvent and completely dissolve at room temperature to obtain the magnesium compound solution, then add the modified carrier, sti...

Embodiment 2

[0330] It is basically the same as embodiment 1, but has the following changes:

[0331] Before the reaction for treating the composite carrier with the chemical treatment agent, the auxiliary chemical treatment agent methylaluminoxane (MAO, 10wt% toluene solution) is used to treat the composite carrier.

[0332] Wherein, the molar ratio of the magnesium compound based on Mg element to the auxiliary chemical treatment agent methylaluminoxane is 1:0.3.

[0333] The supported non-metallocene catalyst is referred to as CAT-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com