Recycling method of hydrocarbon oil metal-removing agent

A demetallizing agent and hydrocarbon oil technology, which is applied in the refining of hydrocarbon oil, petroleum industry, and multi-stage series refining process treatment, etc., can solve the problems of short service life of resin, limited removal rate, serious environmental pollution, etc. Achieve high efficiency, strong practicability and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Hydrocarbon oil demetallizer: 10% demetallizer + 90% demulsifier;

[0028] Ordinary third-line distillate oil: calcium 41.3mg / L, magnesium 2.98mg / L, sodium 18.8mg / L, vanadium 13.1mg / L, sulfur 1310mg / L;

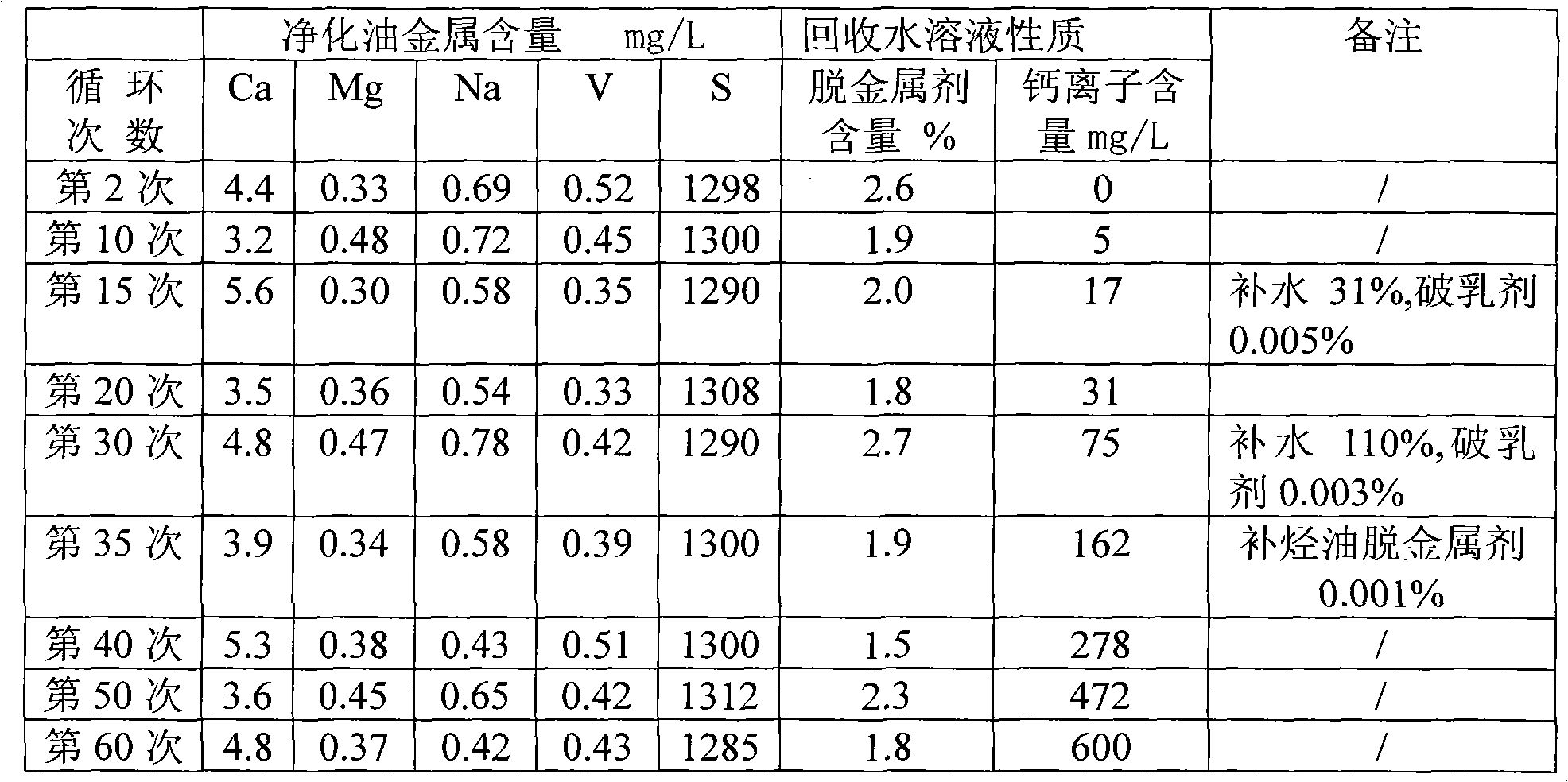

[0029]Mix 0.002% of the hydrocarbon oil demetallizing agent and 5% water with the normal three-line distillate oil at 100°C with a static mixer at a mixing pressure difference of 0.5MPa for 2 minutes to control the diameter of the oil-water particles at Within the range of 0.1 μm to 50 μm, put it in an electric desalting tank, and act for 20 / 10 minutes under the conditions of desalination temperature of 100°C and strong and weak electric fields of 1500 / 100v / cm respectively. After oil and water are separated, analyze the calcium content / decalcification rate of the purified oil 2.0mg / L / 95.2%, magnesium content / magnesium removal rate 0.189mg / L / 93.7%, sodium content 0.7mg / L / 96.3%, vanadium content / vanadium removal rate 0.41mg / L / 96.9%, sulfur The content is 1300mg / L. The i...

Embodiment 2

[0038] Hydrocarbon oil demetallizer: 50% demetallizer + 50% demulsifier;

[0039] Crude oil: calcium 265mg / L, magnesium 1.54mg / L, sodium 5.8mg / L, vanadium 2.6mg / L, iron 7.6mg / L;

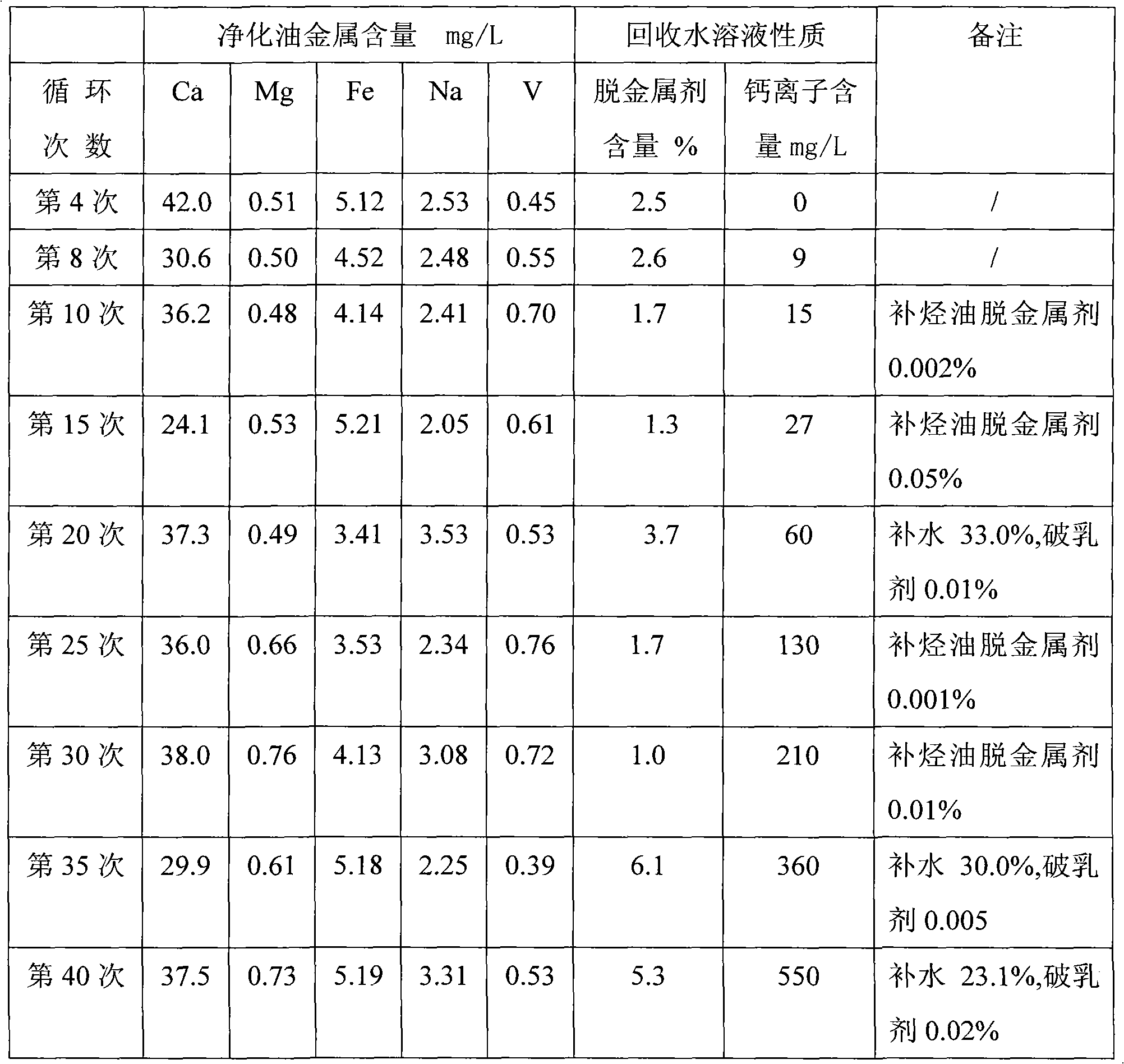

[0040] Mix 0.8% of crude oil with hydrocarbon oil demetallizer, 10% of water and crude oil with a stirrer at 60°C and 0.1MPa for 30 minutes, put them in an electric desalting tank, desalting temperature at 50°C, and strong and weak electric fields are respectively 1000 / 500v / cm for 60 / 20min, after oil-water separation, analysis of calcium content / decalcification rate in the purified oil was 27.8mg / L / 89.5%, magnesium content / magnesium removal rate was 0.412mg / L / 73.2%, sodium content 3.3mg / L / 43.1%, vanadium content / removal rate 0.342mg / L / 86.8%, iron content 5.60mg / L / 26.3%. The isolated desalted aqueous solution containing metal salts adopts the GB7476-87 test method (determination of calcium content in water by EDTA titration method) to measure that the calcium content in water is 0.35%. After the desa...

Embodiment 3

[0050] Hydrocarbon oil demetallizer: 99.5% demetallizer + 0% demulsifier + 0.5% water

[0051] Crude oil: calcium 680mg / L, magnesium 5.02mg / L, iron 20.6mg / L, sodium 45mg / L, vanadium 3.10mg / L

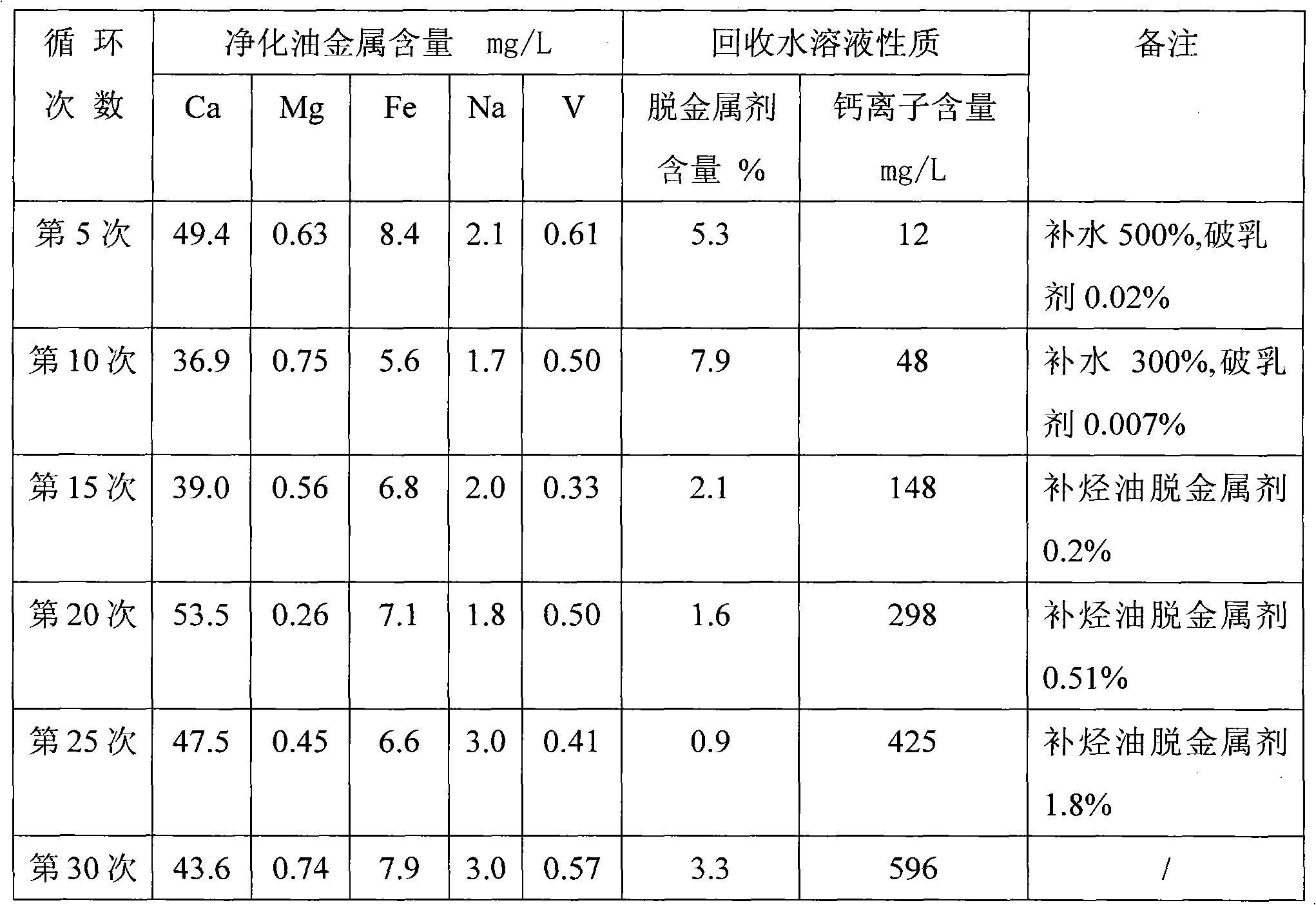

[0052] Cut the hydrocarbon oil demetallizing agent accounting for 2% of crude oil, 20% of water and crude oil with a shearing instrument at a temperature of 50°C and a pressure of 0.5Mpa until the diameter of the oil-water particles is within the range of 0.1 μm to 50 μm, and set In the electric desalting tank, the desalination temperature is 150°C, and the strong and weak electric fields are 500 / 50v / cm respectively, and the action is 200 / 60min. After the oil and water are separated, the calcium content in the purified oil is analyzed / the decalcification rate is 45.0mg / L / 93.4%. Magnesium content / magnesium removal rate is 0.61mg / L / 87.8%, sodium content is 2.3mg / L / 94.9%, vanadium content / vanadium removal rate is 0.25mg / L / 91.9%, iron content is 5.1mg / L / 75.2% . The isolated desalted aqueou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com