Method for extracting bioflocculant

A biological flocculant and flocculant technology, applied in the direction of biochemical equipment and methods, microorganisms, microorganisms, etc., can solve the problems of high cost and large dosage, and achieve the effects of low cost, easy operation and convenient material collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution will be explained in detail below in conjunction with specific embodiments of the present invention:

[0020] The preparation embodiment of flocculant:

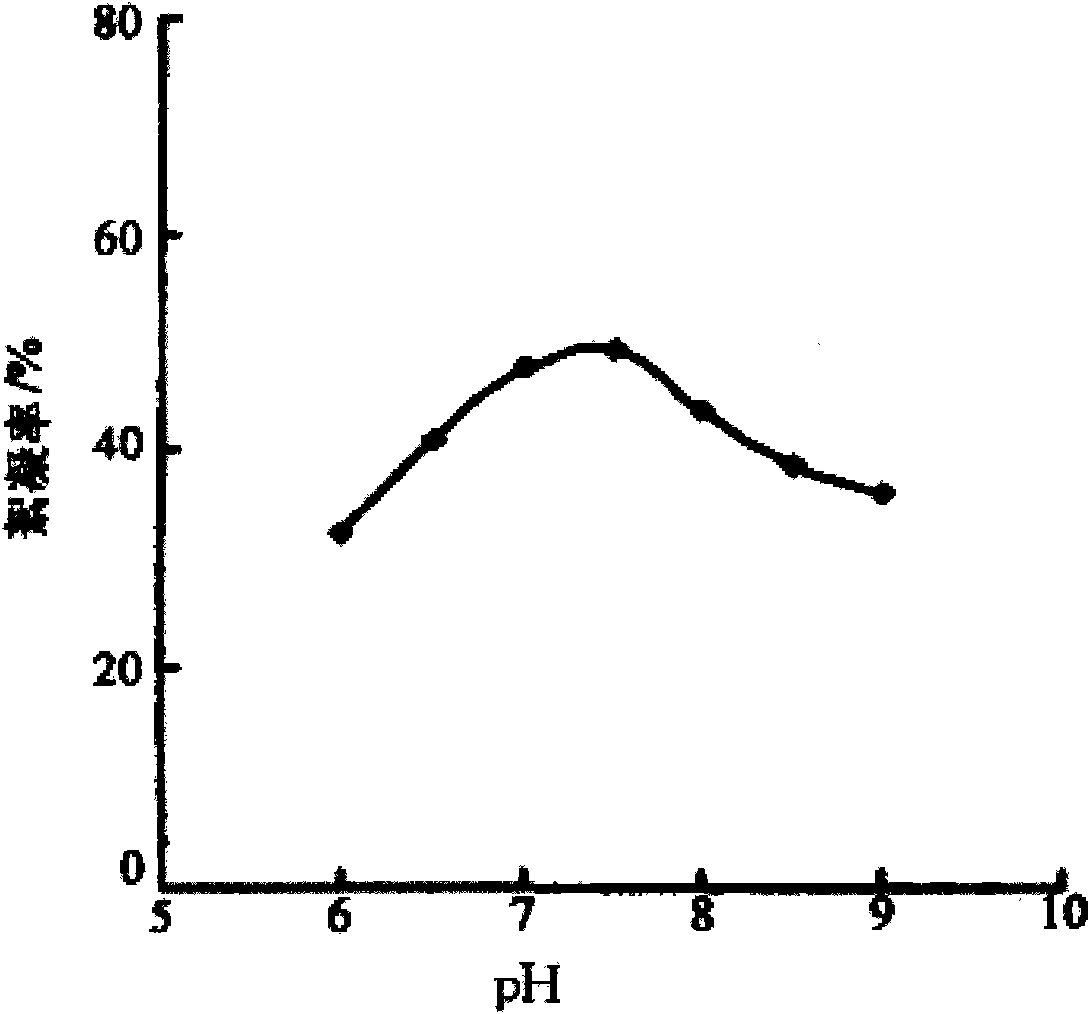

[0021] The strains are derived from the activated sludge of the aeration tank of the sewage plant in the east area of Yangpu District, Shanghai. The basal medium: beef extract peptone medium; the screening medium (also known as glucose medium): glucose 20g, KH 2 PO 4 0.2g, K 2 HPO 4 0.5g, (NH 4 ) 2 SO 4 0.2g, NaCl 0.1g, urea 0.5g, yeast extract 0.5g, MgSO4 7H 2 O 0.2 g (2% agar) was added to 1000 mL of water, and several portions of medium with a pH of 6.0 to 9.0 were prepared respectively, and sterilized at 112° C. for 30 min.

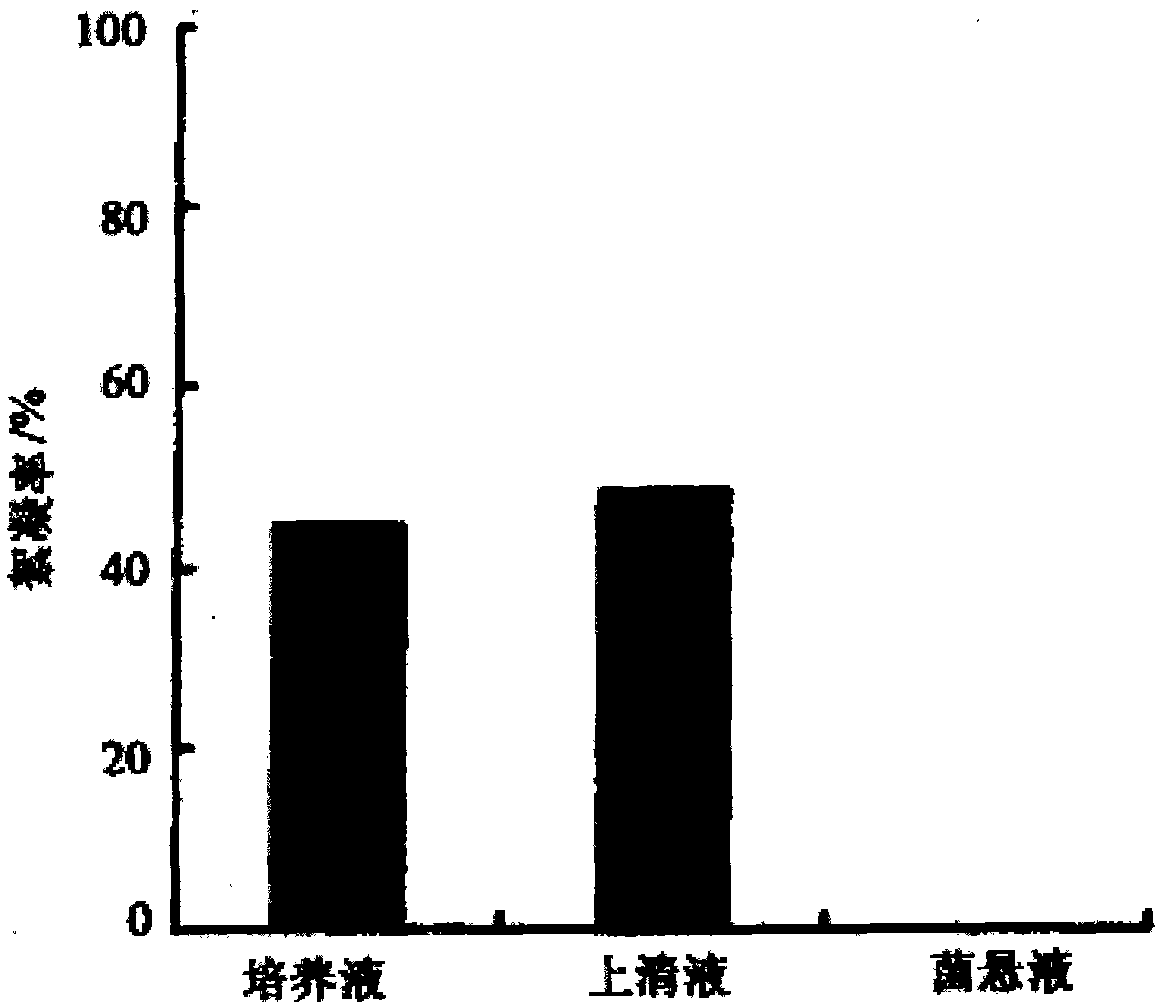

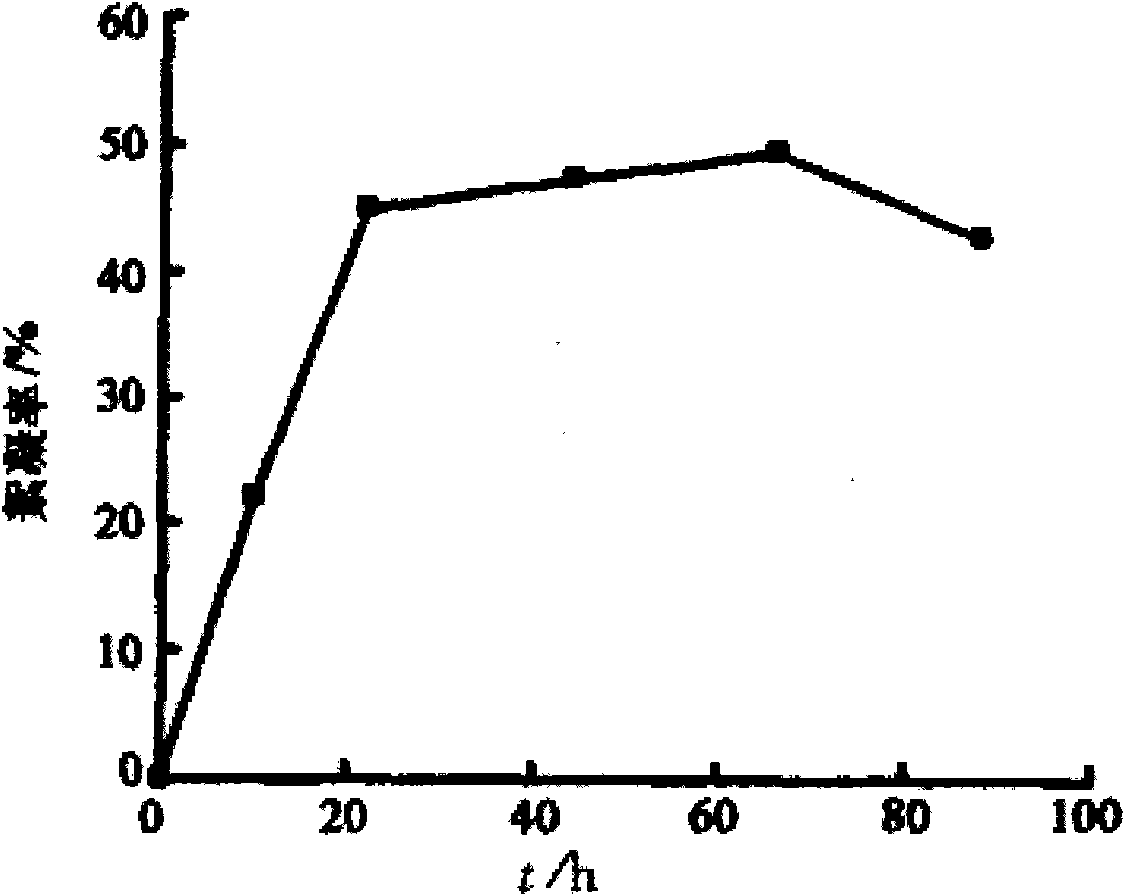

[0022] 1. Bacterial strain screening: after the activated sludge is diluted, put it on a constant temperature shaker at 30°C, enrich and cultivate it at 160r / min for 3 days, obtain a single colony by the dilution plate coating method, and number it after puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com