Sea bottom natural gas hydrate gas lift mining method and device

A mining method and hydrate technology, which is applied in the fields of mining fluids, wellbore/well valve devices, earthwork drilling, etc., can solve the problems of small heating area, unstable fluid production, large energy consumption, etc., and achieve stable working conditions , Low operating cost and small demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

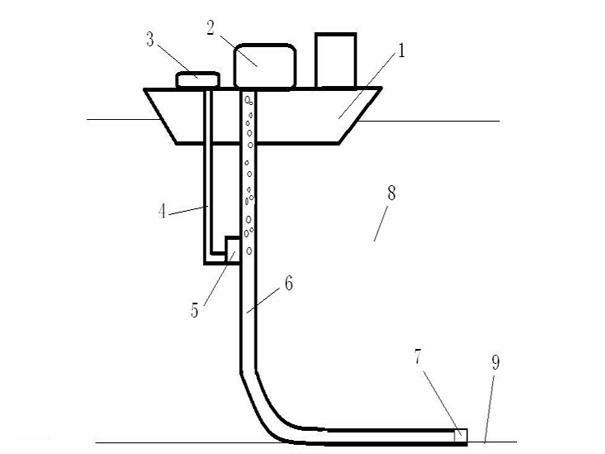

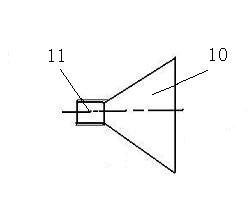

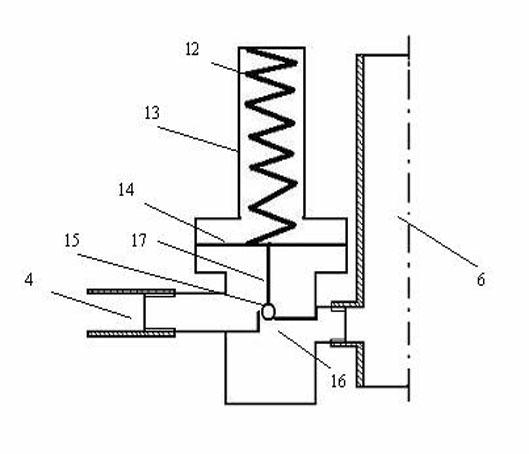

[0017] see figure 1 , install a natural gas separation and storage system 2 and an injected gas storage and pressurization system 3 on the offshore gas production platform or ship 1 . The gas pressurization system in the storage and pressurization system 3 may be a centrifugal pump, or may be other types of explosion-proof gas compression pumps. The natural gas separation and storage system 2 is connected to the outlet of the gas production pipeline 6 . The gas production pipeline 6 extends downward into the seawater 8. The lower opening of the gas production pipeline 6 is the gas production pipeline inlet 7, and the gas production pipeline 6 extends into the seabed natural gas hydrate and sediment mixed layer 9 through the gas production pipeline inlet 7. The gas production pipeline 6 is a channel for the subsea natural gas hydrate, water and sediment mixture to flow to the sea surface. Several metal or non-metallic or composite pipelines are connected by couplings. Coiled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com