Semiconductor device

A semiconductor, conductive type technology, applied in the direction of semiconductor devices, electric solid devices, diodes, etc., can solve the problems of stronger and larger electric field strength, increase of leakage current of diodes, etc., to reduce on-state resistance and suppress leakage current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

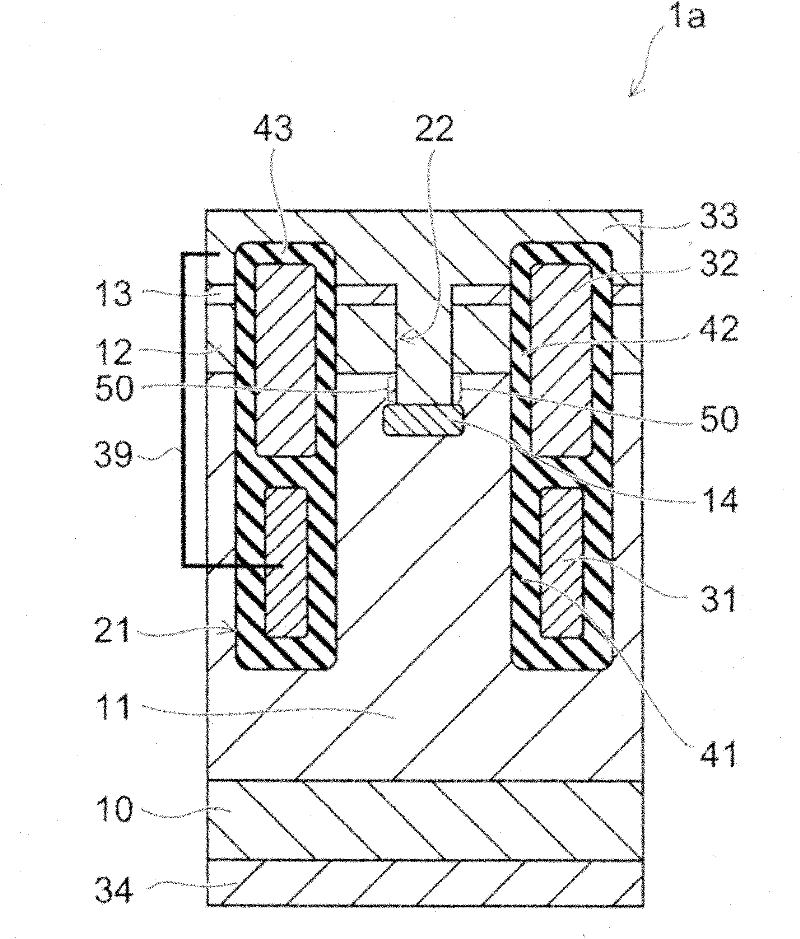

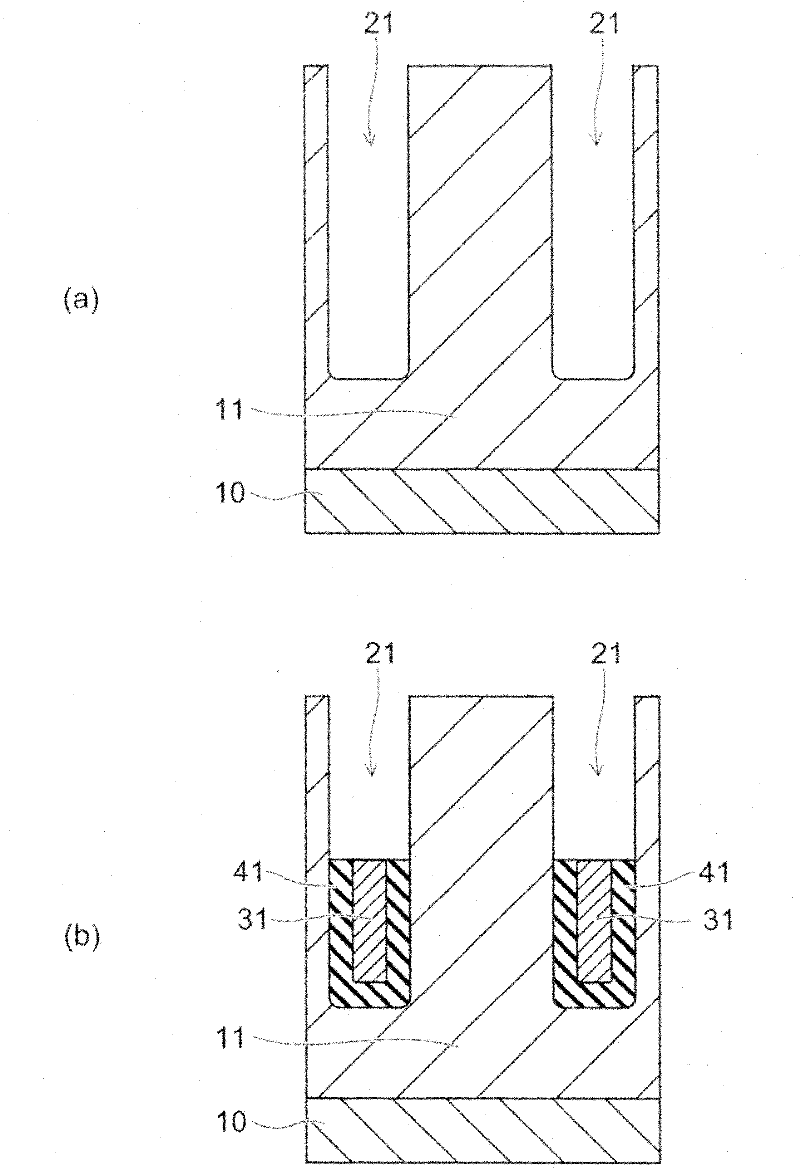

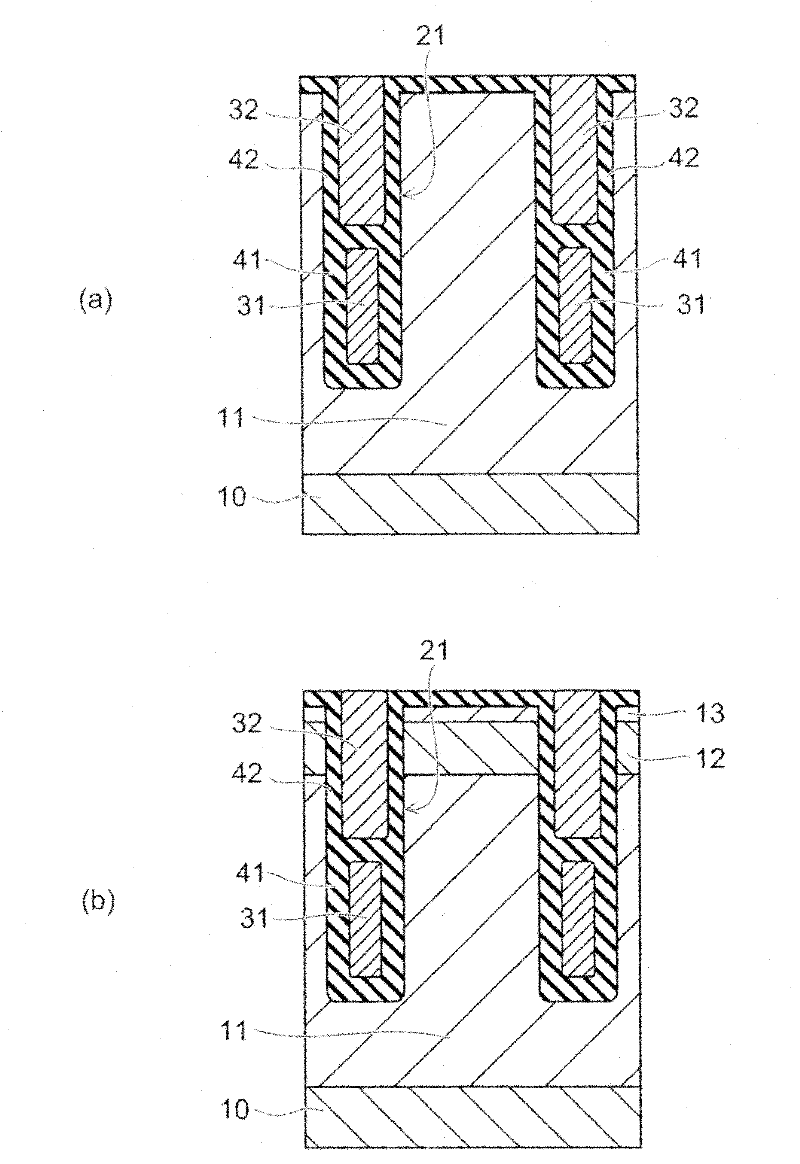

[0025] figure 1 It is a schematic sectional view of a main part of the semiconductor device according to the first embodiment. figure 1 An element portion of a semiconductor device is shown. in the later Figure 2 to Figure 9 in the same way.

[0026] The semiconductor device 1 a includes a power MOSFET having a structure of upper and lower electrodes, and a Schottky barrier diode (hereinafter referred to as SBD). In the semiconductor device 1a, such as figure 1 shown, in n + An n-type drift layer (first semiconductor layer) 11 is provided above the n-type drain layer 10 . A p-type base layer (second semiconductor layer) 12 is formed on the surface of the drift layer 11 . Formed on the surface of the base layer 12 are n + type source layer (third semiconductor layer) 13 . In this embodiment, the embodiment will be described with the drain layer 10 side as the lower side and the source layer 13 as the upper side. That is, the source layer 13 is provided at a shallower ...

no. 2 approach

[0071] Figure 8 It is a schematic cross-sectional view of a main part of the semiconductor device according to the second embodiment.

[0072] Such as Figure 8 As shown, in the semiconductor device 2a, an n-type high-concentration semiconductor layer (fifth semiconductor layer) 15 is provided on the lower side of the base layer 12 in the region A between the trenches 21 and 22. The high-concentration The semiconductor layer 15 contains impurities at a concentration higher than that of the drift layer. The lower end of the high-concentration semiconductor layer 15 is located shallower than the lower end of the guard ring layer 14 . The impurity concentration of the high-concentration semiconductor layer 15 is about several times that of the drift layer 11 . The main component of the high-concentration semiconductor layer 15 is, for example, silicon (Si). In a part of the sidewall of the trench 22 , the metallic source electrode 33 is in contact with the high-concentration...

no. 3 approach

[0080] Figure 10 It is a schematic sectional view of a main part of the semiconductor device according to the third embodiment.

[0081] Figure 10 In FIG. 2 , not only the element region 71 where the MOSFET is formed, but also the termination region 72 from the element region 71 to the outside is shown. That is, the semiconductor device has an element region 71 and a termination region 72 disposed outside the element region 71 around the element region 71 . The element region 71 is a region where the main current path is formed between the drain electrode and the source electrode of the MOSFET, for example, in Figure 10 The middle is a region including the gate electrode 32 and the like. The termination region 72 is a region arranged around the element region 71 on its outer peripheral side, and is a region provided with a field plate electrode 35 , a field insulating film 44 , etc. which will be described later. In the termination region 72 , a field insulating film 44...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com