Composite silica gel humidity adjusting agent

A moisture conditioner, silica gel technology, applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve problems such as poor moisture release performance, and achieve the effects of easy packaging, easy portability, large moisture absorption and moisture capacity

Inactive Publication Date: 2012-04-11

EAST CHINA UNIV OF SCI & TECH +1

View PDF0 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0013] Organic polymer humidity control materials are often composed of super absorbent resins with a three-dimensional cross-linked network structure, such as starch, polyacrylic acid, sodium polyacrylate, polyacrylamide, polyvinyl alcohol, acrylonitrile, etc., which have a large water absorption capacity and can Up to hundreds to thousands of times its own mass, but the moisture release performance is very poor, and the adsorbed water is difficult to desorb

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0027] Weigh 400g of B-type silica gel and put it in a blast dryer, bake it at 120°C for 2 hours, take it out, and put it in a desiccator to cool to room temperature. Weigh 128.0g of lithium chloride monohydrate, dissolve it in 800mL (about 640g of absolute ethanol), let it stand for 20 hours, and filter it. Place it in a blast dryer at 120°C for 4 hours. Finally, pass through a 12-mesh sieve to obtain the product.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

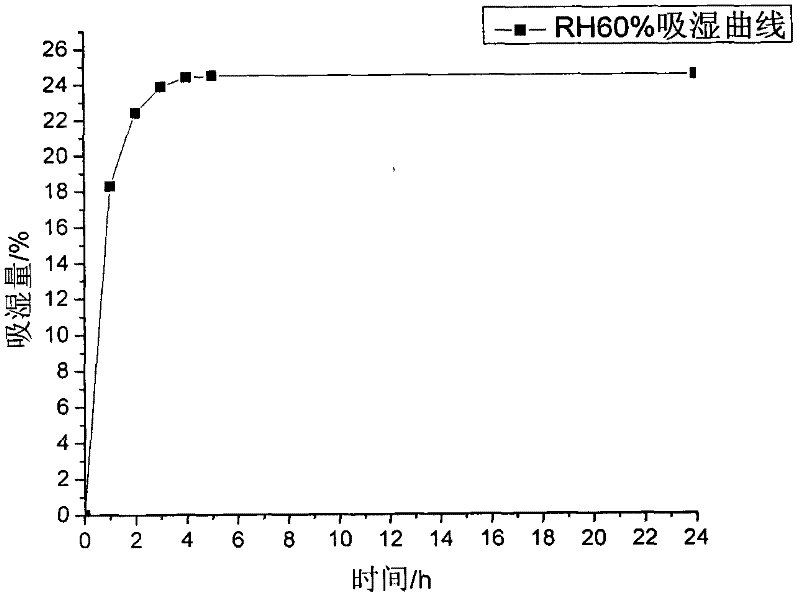

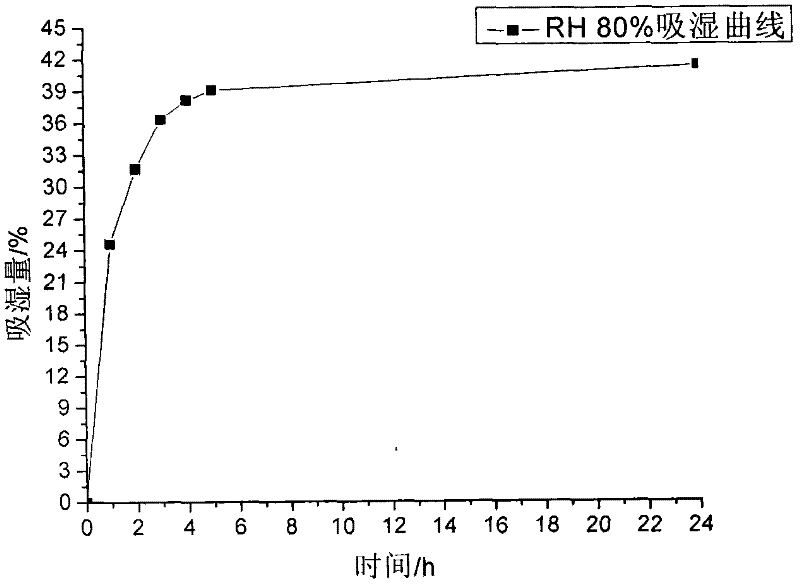

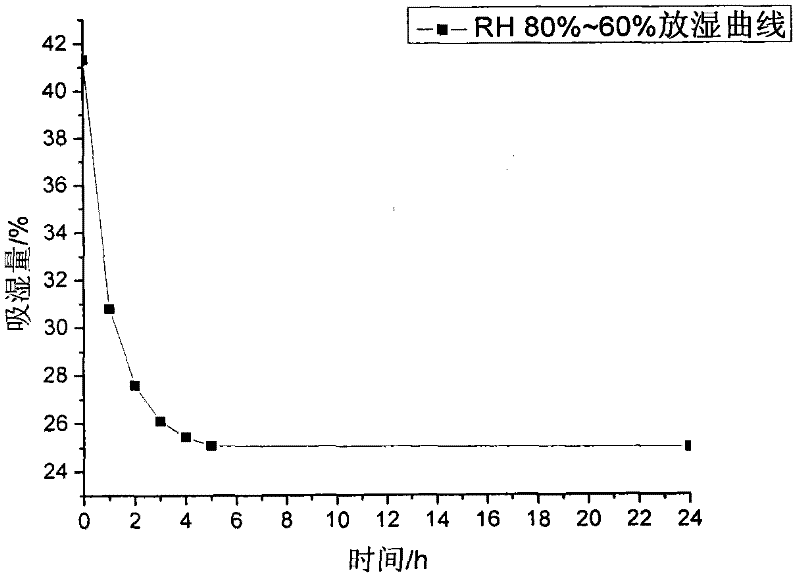

The invention provides a composite silica gel humidity adjusting agent, wherein a silica gel is taken as a matrix, and the silica gel is compounded with inorganic salt, so that the silica gel humidity adjusting agent is prepared. The weight of the inorganic salt is 3-20% of that of the composite silica gel humidity adjusting agent. The composite silica gel humidity adjusting agent is characterized by being prepared through the following steps of: dipping the silica gel into an inorganic salt water or alcoholic solution with a certain concentration, filtering, drying, and sieving so as to obtain a plurality of white spherical grains, wherein the grain diameters of the white spherical grains are within the range from 1.0mm to 5.0mm. The composite silica gel humidity adjusting agent has the advantages that the composite silica gel humidity adjusting agent is an accurate humidity adjusting and controlling product, a reaction can be quickly preformed in the case that the humiture of an external environment is changed, and the humiture within a certain space range can be kept constant by the means that the steam is absorbed and desorbed. The wet capacity of the composite silica gel humidity adjusting agent is more than or equal to that of similar adjusting products at home and abroad; and the composite silica gel humidity adjusting agent is stable in performance under a normal temperature, easy to pack, convenient to carry, nonhazardous, lower in regeneration temperature after the composite silica gel humidity adjusting agent is used, and reusable, thereby being a product which is environmentally-friendly and energy-saving.

Description

technical field [0001] The invention relates to a humidity control material, which has a good effect especially on the control of the relative humidity of the microenvironment of cultural relics collected in museums. Composite silica gel humidity control agent can control the relative humidity of a relatively closed space with a certain volume within a certain range, and adjust the humidity by automatically absorbing and dehumidifying the humidity by sensing the change of ambient temperature and humidity, without consuming power, and can be recycled and utilized. A new type of debugging material with high precision, low carbon and environmental protection. Background technique [0002] The relative humidity of indoor air is an important parameter to measure the indoor environment. Proper humidity is of great significance to human health, indoor air quality, product production process, product quality and article protection. The national "Air Quality Standard" stipulates th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J20/10

Inventor 张文清夏玮张楠张玉龙罗曦芸吴来明

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com