Preparation method of macroporous large specific surface magnetic photocatalyst Fe3O4/TiO2

A high specific surface, visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve difficulties and other problems, and achieve the effect of simple method, rapid solid-liquid separation, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

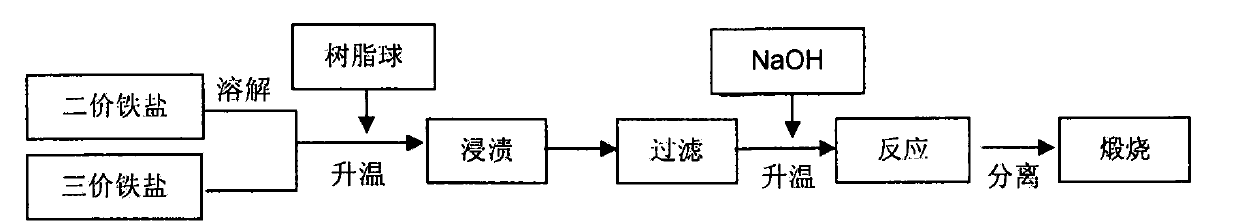

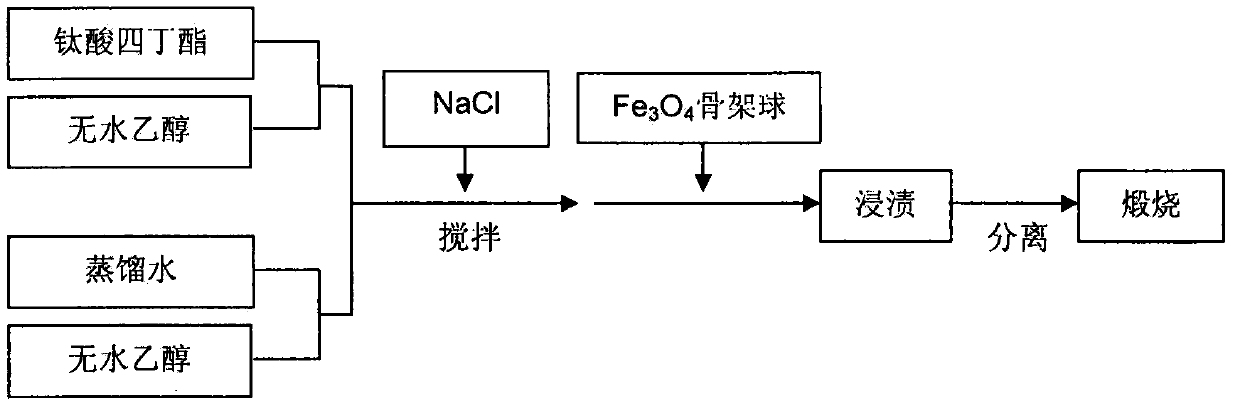

[0025] Fe(NO 3 ) 2 ·6H 2 O and Fe 2 (SO 4 ) 3 9H 2 O is dissolved in 50mL distilled water according to the iron ion molar ratio of 1:2, and is prepared into an aqueous solution with a total iron ion molar fraction of 1.8%, and is added to the 2In the four-necked bottle with the device and thermometer, start stirring and add 10 parts of macroporous cross-linked polystyrene microspheres to it, the system is heated up to 45°C, and the temperature is maintained for 4h, then poured out, filtered and collected. Add polystyrene microspheres into a 100mL Erlenmeyer flask with a stopper, and put the flask into a constant temperature water bath. When the temperature rises to 80°C, add 5 parts of sodium hydroxide to it, shake gently for 1min and then keep the temperature After reacting for 50min and cooling to room temperature, Fe was obtained by magnetic separation 3 o 4 / polystyrene microspheres, put them into a muffle furnace, calcinate at 600°C for 5h in a nitrogen atmosphere...

Embodiment 4

[0029] FeCl 2 4H 2 O and Fe(NO 3 ) 3 9H 2 O is dissolved in 50mL distilled water according to the iron ion molar ratio of 1:2, and is prepared into an aqueous solution with a total iron ion molar fraction of 1.9%, and is added to the 2 In the four-necked bottle of the device and thermometer, start stirring and add 8 parts of macroporous cross-linked polydivinylbenzene microspheres to it, the system is heated up to 55°C, and the temperature is maintained for 3h, then poured out, filtered and collected. Pore cross-linked polydivinylbenzene microspheres were added to a 100mL Erlenmeyer flask with a stopper, and the flask was placed in a constant temperature water bath. When the temperature rose to 65°C, 4 parts of sodium hydroxide was added to it, and gently Shake for 1 min, then react at constant temperature for 1 h, cool to room temperature, and obtain Fe by magnetic separation 3 o 4 / polydivinylbenzene microspheres, put them into a muffle furnace, calcinate at 800°C fo...

Embodiment 5

[0031] FeSO 4 ·7H 2 O and FeCl 3 ·6H 2 O is dissolved in 50mL distilled water according to the iron ion molar ratio of 1:2, and is prepared into an aqueous solution with a total iron ion molar fraction of 3%, and is added to the 2 In the four-necked bottle with the device and thermometer, start stirring and add 7 parts of macroporous cross-linked polyacrylonitrile microspheres to it, the system is heated up to 45°C, keep this temperature for 5h, pour out, filter and collect the impregnated macroporous cross-linked polyacrylonitrile microspheres. Add polyacrylonitrile microspheres into a 100mL Erlenmeyer flask with a stopper, and put the flask into a constant temperature water bath. When the temperature rises to 70°C, add 5 parts of sodium hydroxide to it, shake gently for 1min and then keep the temperature After reacting for 45min and cooling to room temperature, Fe was obtained by magnetic separation 3 o 4 / polyacrylonitrile microspheres, put them into a muffle furnace, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com