Catalyst used for preparing synthetic natural gas by using coal derived synthesis gas and preparation method thereof

A technology for synthesizing natural gas and coal-based synthesis gas, which is applied in the fields of gas fuel, petroleum industry, fuel, etc., can solve the problems of few industrialization achievements, etc., and achieve the effects of high activity and stability, easy production and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

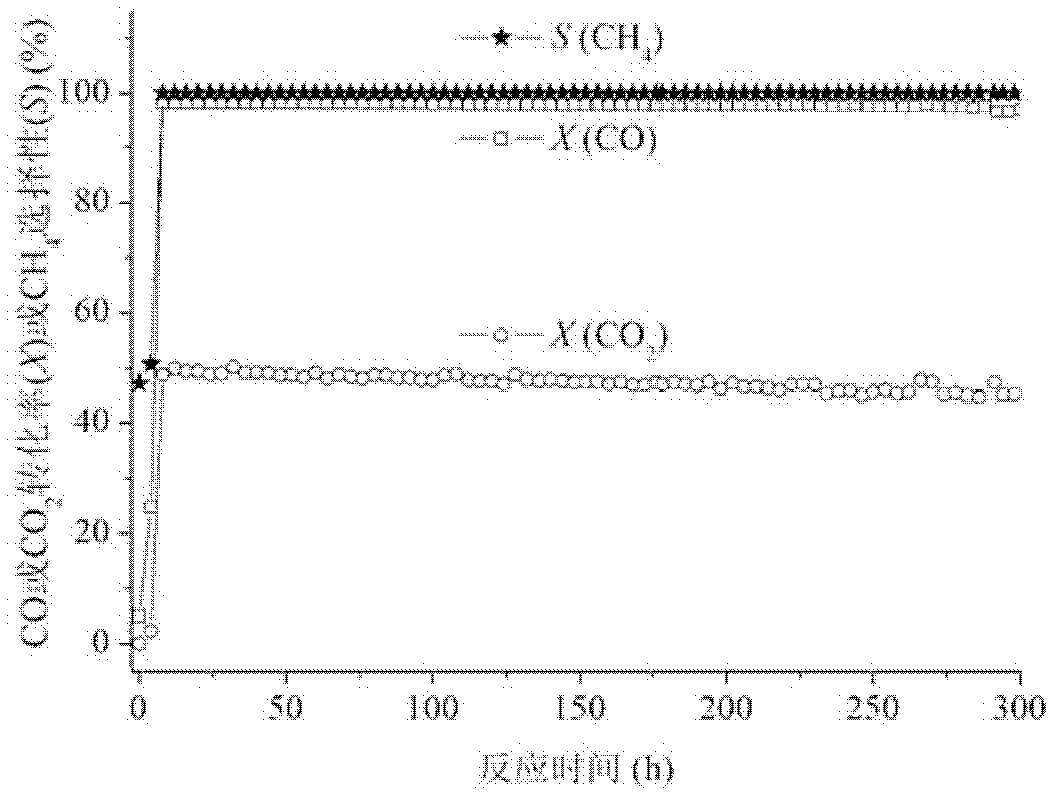

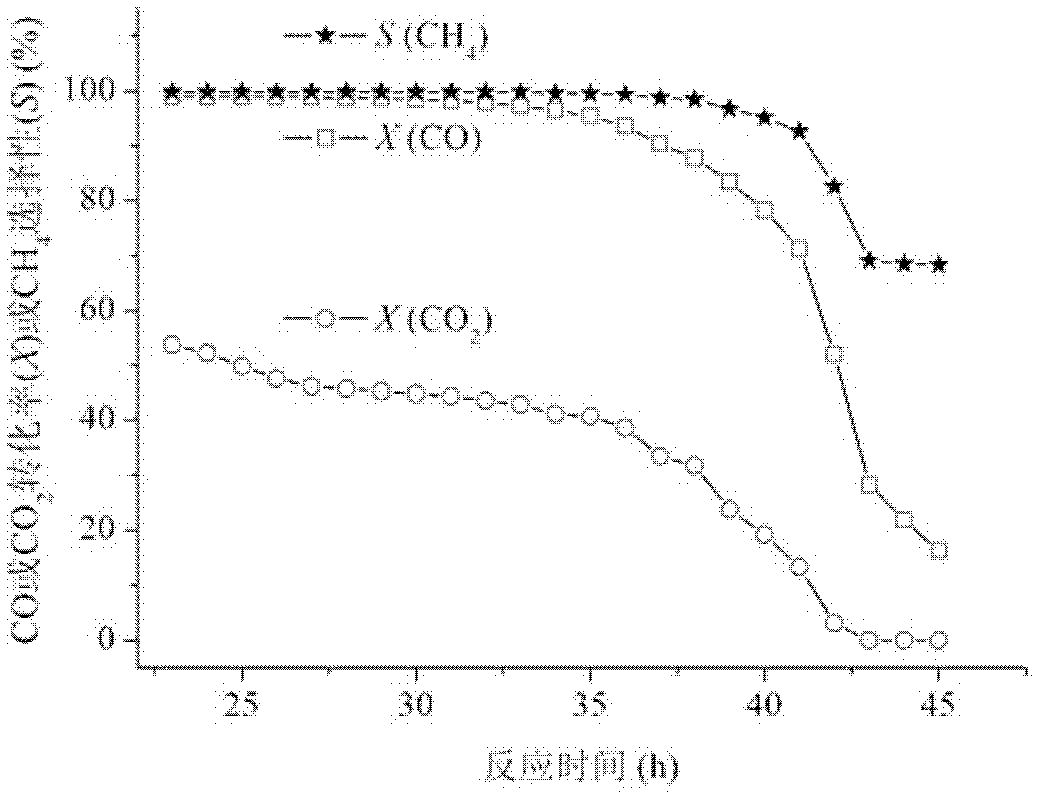

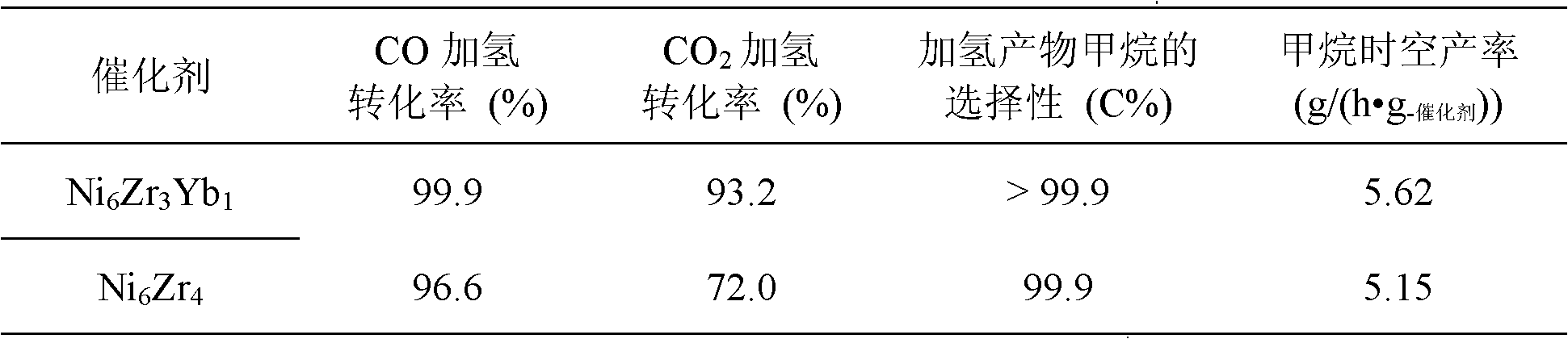

Examples

Embodiment 1

[0021] 6.98gNi(NO 3 ) 2 ·6H 2 O, 4.72gZr(NO 3 ) 4 ·3H 2 O and 1.87g Yb(NO 3 ) 3 ·6H 2 O (purity are all AR grade) mixed together, add 90mL deionized water to prepare solution A.

[0022] 7.46g AR grade anhydrous K 2 CO 3 Dissolve in 90mL deionized water to prepare solution B; at 80°C, inject solutions A and B into a reaction vessel at an equal velocity (injection rate: 12mL / min), and carry out under the condition of constant temperature at 80°C and constant stirring. coprecipitation reaction, by regulating the K 2 CO 3 Add the amount of aqueous solution to keep the pH value of the precipitation solution in the range of 7.2 to 7.8. After the addition, continue to stir for 30 minutes and then stop stirring. Immediately filter the feed solution, and the obtained precipitate is washed with deionized water until it reaches K in the eluent. + The ion concentration is below 0.ppm (detected by flame ion absorption method), after filtration, the filter cake is dried at 110°...

Embodiment 2

[0032] 8.14gNi(NO 3 ) 2 ·6H 2 O, 4.72gZr(NO 3 ) 4 ·3H 2 O and 1.87g Yb(NO 3 ) 3 ·6H 2 O (purity are all AR grade) mixed together, add 90mL deionized water to prepare solution A; another 8.06g AR grade anhydrous K 2 CO 3 Dissolve in 90mL deionized water to prepare solution B; at 90°C, inject solutions A and B into a reaction vessel at an equal velocity (injection speed: 12mL / min), and carry out under the condition of constant temperature at 90°C and constant stirring. coprecipitation reaction, by regulating the K 2 CO 3 Add the amount of aqueous solution to keep the pH value of the precipitation solution in the range of 7.2 to 7.8. After the addition, continue to stir for 30 minutes, then stop stirring, and filter the feed solution immediately; the obtained precipitate is washed with deionized water until K in the eluent. + The ion concentration is below 0.1ppm (detected by flame ion absorption method), after filtration, the filter cake is dried at 110°C for 24 hours...

Embodiment 3

[0035] 5.82gNi(NO 3 ) 2 ·6H 2 O, 4.72gZr(NO 3 ) 4 ·3H 2 O and 1.87g Yb(NO 3 ) 3 ·6H 2 O (purity are all AR grade) mixed together, add 90mL deionized water to prepare solution A; another 6.94g AR grade anhydrous K 2 CO 3 Dissolve in 90mL deionized water to prepare solution B; at 80°C, inject solutions A and B into a reaction vessel at an equal velocity (injection speed: 12mL / min), and carry out under the condition of constant temperature at 80°C and constant stirring. coprecipitation reaction, by regulating the K 2 CO 3 Add the amount of aqueous solution to keep the pH value of the precipitation solution in the range of 7.2 to 7.8. After the addition, continue to stir for 30 minutes, then stop stirring, and filter the feed solution immediately; the obtained precipitate is washed with deionized water until K in the eluent. + The ion concentration is below 0.1ppm (detected by flame ion absorption method), after filtration, the filter cake is dried at 110°C for 24 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com