Attapulgite/hydrotalcite compound flame retardant material and preparation method thereof

An attapulgite and composite flame retardant technology, which is applied in the field of attapulgite/hydrotalcite composite flame retardant materials and their preparation, can solve the problems of unsatisfactory smoke suppression effect of flame retardant materials, and achieves excellent reinforcing effect, inhibits long big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

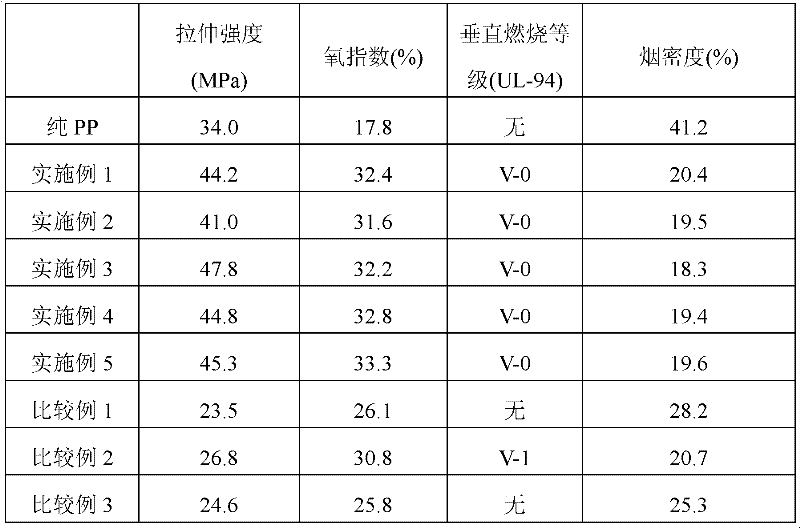

Examples

Embodiment 1

[0021] 1. To 2048 grams of solid Mg (NO 3 ) 2 ·6H 2 O and 1500 g of solid Al(NO 3 ) 3 9H 2 Add deionized water into O to make 10 liters of mixed solution A;

[0022] 2. To 40 liters, the molar concentration is 1mol L -1 Add 790 grams of solid ammonium bicarbonate to ammonia water to prepare mixed solution B;

[0023] 3. Heat up 6000 grams of attapulgite water-dispersed slurry with a mass percentage of 10% to 80°C, add 154.8 grams of potassium stearate, and while stirring, add mixed solution A and Mix solution B, keep the temperature of the system at 80°C during the process, and the pH value of the system is 11.0. After adding the mixed solution A, stop adding the mixed solution B dropwise, continue to stir and keep it warm for 5 hours, and then pass carbon dioxide gas to the pH of the system. Value is 8.5, obtains attapulgite / hydrotalcite composite slurry;

[0024] 4. Filtration, washing, vacuum drying of the filter cake at 80°C for 10 hours, and pulverization by a QYF...

Embodiment 2

[0026] 1. To 3248 grams of solid MgCl 2 ·6H 2 O and 966 grams of solid Al(Cl) 3 ·6H 2 Add deionized water into O to make 10 liters of mixed solution A;

[0027] 2. To 30 liters, the molar concentration is 3mol L -1 Add 2370 grams of solid ammonium bicarbonate to ammonia water to prepare mixed solution B;

[0028] 3. Heat up 32.3 kg of attapulgite water-dispersed slurry with a mass percentage of 5% to 100°C, add 35.6 g of sodium laurate, and while stirring, add mixed solution A into the attapulgite slurry and mix For solution B, the temperature of the process maintenance system is 100°C, and the pH value of the system is 11.5. After adding the mixed solution A, stop adding the mixed solution B dropwise, continue to stir and keep it warm for 2 hours, and then pass carbon dioxide gas to the pH value of the system. Be 8.0, obtain attapulgite / hydrotalcite composite slurry;

[0029] 4. Filtration and washing, the filter cake was air-dried at 100°C for 3 hours, and pulverized b...

Embodiment 3

[0031] 1. To 2218 grams of solid MgSO 4 ·7H 2 O and 999.6 g of solid Al 2 (SO 4 ) 3 18H 2 Add deionized water into O to make 40 liters of mixed solution A;

[0032] 2. To 120 liters, the molar concentration is 0.5mol L -1 Add 2370 grams of solid ammonium bicarbonate to ammonia water to prepare mixed solution B;

[0033]3. Heat up 13.25 kg of attapulgite water-dispersed slurry with a mass percentage of 20% to 70°C, add 219 g of sodium oleate, and while stirring, add mixed solution A into the attapulgite slurry and mix Solution B, the temperature of the process maintenance system is 70°C, and the pH value of the system is 10.0. After adding the mixed solution A, stop adding the mixed solution B dropwise, continue to stir and keep it warm for 24 hours, and then pass carbon dioxide gas to the pH value of the system Be 9.0, obtain attapulgite / hydrotalcite composite slurry;

[0034] 4. Filter, wash, dry the cake at 110°C for 2 hours, and pulverize it with a QYF-100 airflow m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com