Comprehensive treatment process of waste gold-bearing activated carbon

A comprehensive treatment and activated carbon technology, applied in the direction of improving process efficiency, can solve problems such as low efficiency, weakened ability to absorb gold and silver, and incomplete treatment, so as to increase economic benefits, improve comprehensive utilization of resources, and improve gold and silver recovery. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

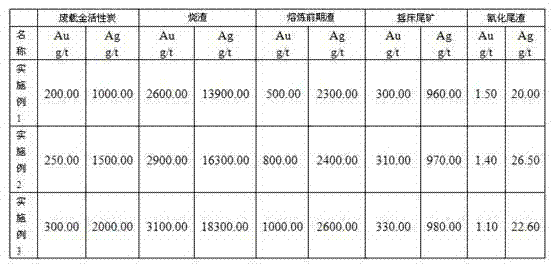

Embodiment 1

[0021] The technique of the comprehensive treatment of waste gold-loaded activated carbon of the present embodiment,

[0022] The process for the comprehensive treatment of waste gold-loaded activated carbon comprises the following steps:

[0023] 1. Use a charcoal furnace to incinerate to remove charcoal and enrich gold and silver

[0024] Put an appropriate amount of gold-loaded activated carbon containing 200 g / t of gold and 1000 g / t of silver into the charcoal furnace in batches. The temperature is controlled at 800 ° C and fully incinerated for 2.5 hours to enrich the gold and silver in the slag;

[0025] 2. Finely grind the slag and treat it on a shaking table

[0026] The slag enriched in gold and silver is finely ground to a fineness of 150 meshes, and added to a shaker for grading treatment to obtain shaker concentrate and shaker tailings rich in gold and silver. The shaker concentrate contains 1000 g / t of gold, The silver content is 7000 g / t, and the gold content o...

Embodiment 2

[0036] A process for the comprehensive treatment of spent gold-loaded activated carbon, comprising the following steps:

[0037] 1. Use a charcoal furnace to incinerate to remove charcoal and enrich gold and silver

[0038] Put an appropriate amount of gold-loaded activated carbon containing 250 g / t gold and 1500 g / t silver into the charcoal furnace in batches, and control the temperature at 880°C, and fully incinerate for 3 hours to enrich the gold and silver in the slag;

[0039] 2. Finely grind the slag and treat it on a shaking table

[0040] The slag enriched in gold and silver is finely ground to a fineness of 200 meshes, and added to a shaker for grading treatment to obtain shaker concentrate and shaker tailings rich in gold and silver. The shaker concentrate contains 1300 g / t of gold. The silver content is 7500 g / t, and the gold content of the shaker tailings is 550 g / t;

[0041] 3. Shaking table concentrate batching smelting treatment

[0042] The shaker concentrat...

Embodiment 3

[0050] A process for the comprehensive treatment of spent gold-loaded activated carbon, comprising the following steps:

[0051] 1. Use a charcoal furnace to incinerate to remove charcoal and enrich gold and silver

[0052] Put an appropriate amount of waste gold-loaded activated carbon containing 300 g / t gold and 2000 g / t silver into the charcoal furnace in batches, control the temperature at 900°C, and fully incinerate for 3.5 hours to enrich the gold and silver in the slag;

[0053] 2. Finely grind the slag and treat it on a shaking table

[0054] The slag enriched in gold and silver is finely ground to a fineness of 300 meshes, and then added to a shaker for grading treatment to obtain a shaker concentrate and shaker tailings rich in gold and silver. The shaker concentrate contains 1500 g / t of gold. The silver content is 8000 g / t, and the gold content of the shaker tailings is 800 g / t;

[0055] 3. Shaking table concentrate batching smelting treatment

[0056]Dry the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com