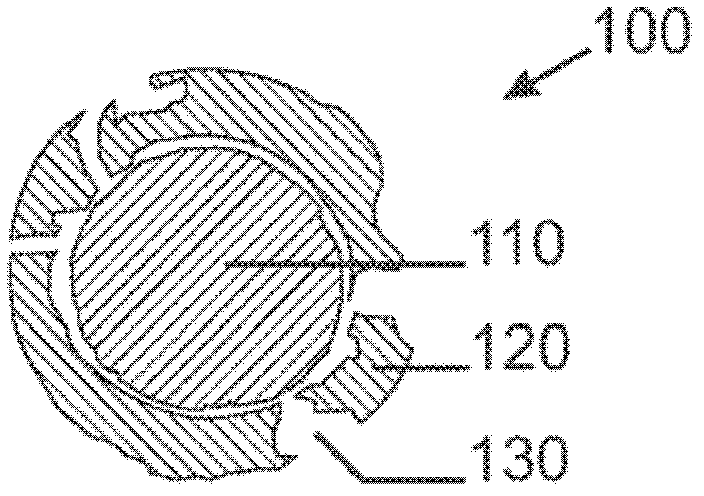

A fixed abrasive sawing wire with a rough interface between core and outer sheath

A technology of consolidating abrasives and sawing wires, which is applied in the direction of abrasives, manufacturing tools, metal sawing equipment, etc., and can solve the problems of increasing kerf loss, loss of useful materials, and loss of core wire strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0093] According to a first example of the present invention, according to methods known in the art, chemically from 0.01 wt% high carbon content wire rod (nominal diameter 5.5 mm) was descaled. The wires were dry drawn to 3.25 mm, sorbitized and again dry drawn to a median diameter D of 1.10 mm.

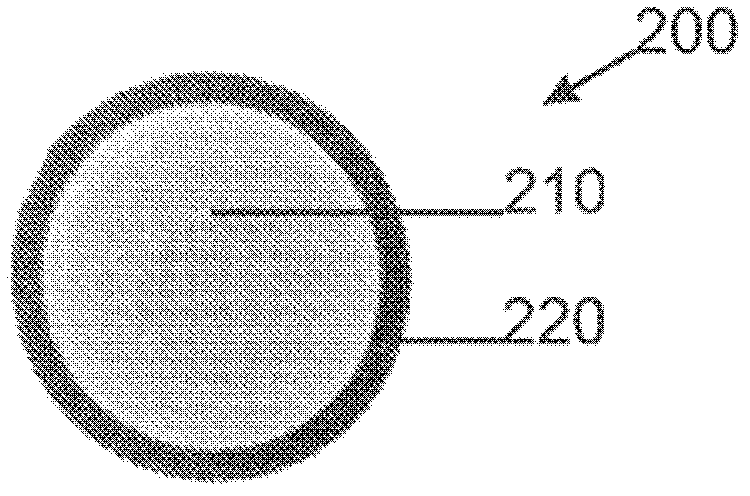

[0094]A copper plating having a thickness Δ of 99 microns or approximately 446.5 grams per kilogram of core wire was electroplated onto this intermediate diameter wire, resulting in an overall diameter D' of 1.298 mm. This is the second middle line. figure 2 A metallographic cross-section of the wire 200 is shown in . The interface between the steel core 210 and the copper sheath 220 is smooth and shows no appreciable roughness. No interdiffusion or alloying between copper and steel occurs.

[0095] In a wet wire drawing operation, the second intermediate wire was sequentially drawn through successively smaller dies until a sheathed core diameter of 205 microns was obtained, wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com