Paraquat-containing water dispersible granules and preparation method thereof

A technology of dispersible granules and paraquat, which is applied in botany equipment and methods, herbicides, algicides, biocides, etc. It can solve the problems of easy ingestion and poisoning by users, high toxicity to humans, etc., and achieve good weeding effect , use the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

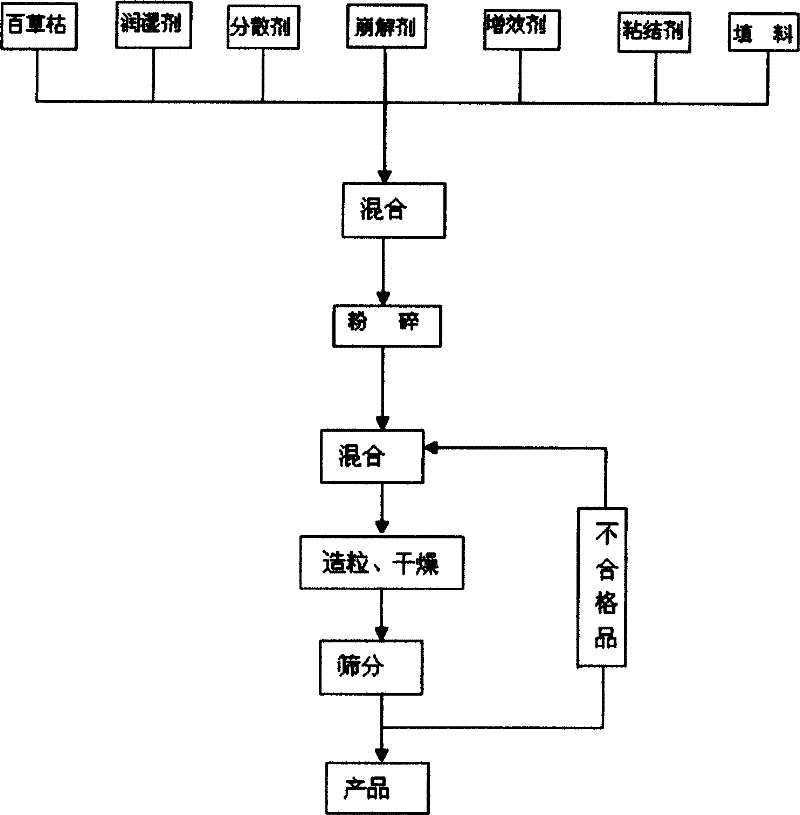

Method used

Image

Examples

Embodiment 1

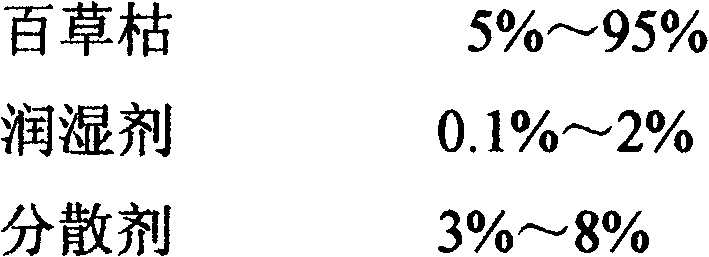

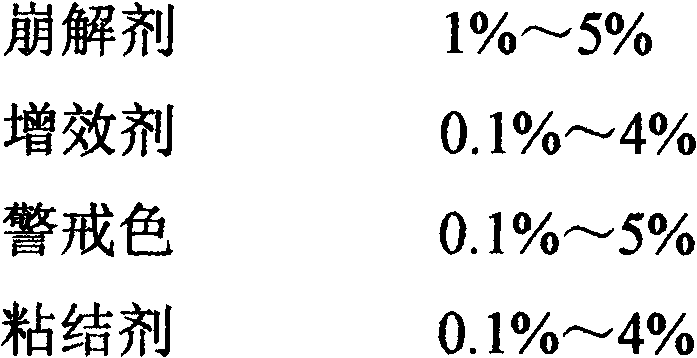

[0029] (1) Select raw materials according to the following components and mix them uniformly: 80g of paraquat technical (weight percentage), 1g of wetting agent sodium lauryl sulfate, 4g of dispersant fatty alcohol polyoxyethylene ether, binder polyoxyethylene ether Ethylene glycol 2g, synergist white sugar 7g, disintegrant anhydrous sodium sulfate 6g;

[0030] (2) Pulverize the above materials to 300-500 mesh;

[0031] (3) Add 6-112 grams of water to the obtained powder to knead, fully mix, then granulate and dry;

[0032] (4) Sieve the dried granules to obtain 95 g of paraquat-containing water-dispersible granules with a content of 75%, and the remaining material can be re-entered into the recycling process.

[0033] After inspection, the content of paraquat in the prepared dispersible granules is 75.2% (weight percent), moisture 0.3% (weight percent), pH value 6.7, sieve rate (through 75um) 98%, fully dissolved in water, lasting The foaming property is 17ml / 1min, the wett...

Embodiment 2

[0035] (1) Select raw materials according to the following components, and mix them uniformly: 80 g of paraquat technical (weight percentage), 1 g of wetting agent sodium lauryl sulfate, 4 g of dispersant alkylphenol polyoxyethylene ether, binder Starch 5g, diatomaceous earth 10%;

[0036] (2) Pulverize the above materials to 300-500 mesh;

[0037] (3) Add 6-112 grams of water to the obtained powder to knead, fully mix, then granulate and dry;

[0038] (4) Sieve the dried granules to obtain 96 g of paraquat-containing water-dispersible granules with a content of 75%, and the remaining material can be re-entered into the recycling process.

[0039] After inspection, the content of paraquat in the prepared dispersible granules is 75.2% (weight percent), moisture 0.3% (weight percent), pH value 6.9, sieve rate (through 75um) 98%, suspension rate 94%, durable The foaming property is 15ml / 1min, the wetting time is 40s, and the accelerated heat storage stability is qualified.

Embodiment 3

[0041] (1) Select raw materials according to the following components, and mix them uniformly: paraquat technical (weight percentage) 80g, wetting agent nonylphenol polyoxyethylene ether 1g, dispersant naphthalenesulfonic acid formaldehyde condensate 5g, filler lactose 14g %;

[0042] (2) Pulverize the above materials to 300-500 mesh;

[0043] (3) Add 6-12 grams of water to the obtained powder to knead, fully mix, then granulate and dry;

[0044] (4) Sieve the dried granules to obtain 96 g of paraquat-containing water-dispersible granules with a content of 75%, and the remaining material can be re-entered into the recycling process.

[0045] After inspection, the content of paraquat in the prepared dispersible granules is 75.2% (weight percent), moisture 0.3% (weight percent), pH value 6.9, sieving rate (passing 75um) 98%, fully dissolved in water, durable The foaming property is 9ml / 1min, the wetting time is 32s, and the accelerated heat storage stability is qualified. It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com