Quick field drying method for alfalfa hay blending

A technology of alfalfa and drying method, which is applied to the preservation method, application and animal feed of animal feed raw materials, which can solve the problems of weak foundation of hay preparation technology, decline of hay product quality, high water content of alfalfa hay, and achieve reduction of stems and leaves The effects of separation, low production cost, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

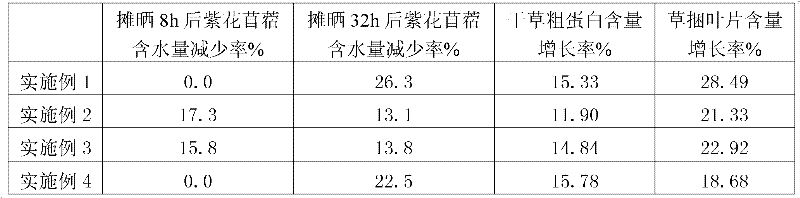

Examples

Embodiment 1

[0038] A field rapid drying method prepared from alfalfa hay, comprising the following steps:

[0039] (1) Pretreatment

[0040] Before the alfalfa is harvested, the drying aid solution is sprayed on the alfalfa. The spraying amount per ton of alfalfa is 15L. The components of the drying aid solution are as follows, all in parts by weight: 2 parts of potassium carbonate, 0.5 parts of potassium hydroxide, 97.5 parts of water.

[0041] (2) Mowing

[0042] The mowing started on May 16, 2010 (the budding stage), the mowing stubble was 4cm-5cm, and the fresh grass yield was 26.05t / hm 2 .

[0043] (3) Flatten

[0044] The distance between the two pressing rollers of the mowing and flattening machine was set to 10 cm, and the stems of the mowed alfalfa were crushed.

[0045] (4) Tanning

[0046] The alfalfa after fracturing the stalks is directly spread in the field, and the alfalfa is arranged in rows, each row has a thickness of 20cm-30cm, a width of 1.1m-1.2m, and the distan...

Embodiment 2

[0052] A field rapid drying method prepared from alfalfa hay, comprising the following steps:

[0053] (1) Pretreatment

[0054] Before the alfalfa is harvested, the drying aid solution is sprayed onto the alfalfa. The spraying amount per ton of alfalfa is 10 L. The components of the drying aid solution are as follows, all in parts by weight: 2 parts of potassium carbonate, 2 parts of potassium chloride, 96 parts of water;

[0055] (2) Mowing

[0056] Started mowing on June 28, 2010 (sprouting stage), with 4cm to 5cm of stubble remaining, and fresh grass yield of 23.10t / hm 2 .

[0057] (3) Flatten

[0058] The distance between the two pressing rollers of the mowing and flattening machine was set at 15 cm, and the stems of the mowed alfalfa were crushed.

[0059] (4) Tanning

[0060] The alfalfa after the stem fracturing is directly spread in the field, and the alfalfa is placed in rows. The thickness of each row is 20cm-30cm, the width is 1.1m-1.2m, and the distance betwee...

Embodiment 3

[0066] A field rapid drying method prepared from alfalfa hay, comprising the following steps:

[0067] (1) Pretreatment

[0068] Before the alfalfa is harvested, the drying aid solution is sprayed onto the alfalfa. The spraying amount per ton of alfalfa is 10 L. The components of the drying aid solution are as follows, all in parts by weight: 3 parts of potassium carbonate, 1.5 parts of sodium bicarbonate, 95.5 parts of water;

[0069] (2) Mowing

[0070] On August 18, 2010 (early flowering stage), the mowing started, the stubble was 4cm~5cm, and the fresh grass yield was 30.20t / hm 2 .

[0071] (3) Flatten

[0072] The distance between the two pressing rollers of the mowing and flattening machine is set to 20 cm, and the stems of the mowed alfalfa are crushed.

[0073] (4) Tanning

[0074] The alfalfa after the stem fracturing is directly spread in the field, and the alfalfa is placed in rows. The thickness of each row is 20cm-30cm, the width is 1.1m-1.2m, and the distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com