Visible-light response calcium-bismuth composite oxide catalyst and preparation method thereof

A composite oxide, catalyst technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the limitations of practical wide application, low utilization of visible light, preparation Complex process and other problems, to achieve high commercial application prospects, good visible light degradation activity, and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

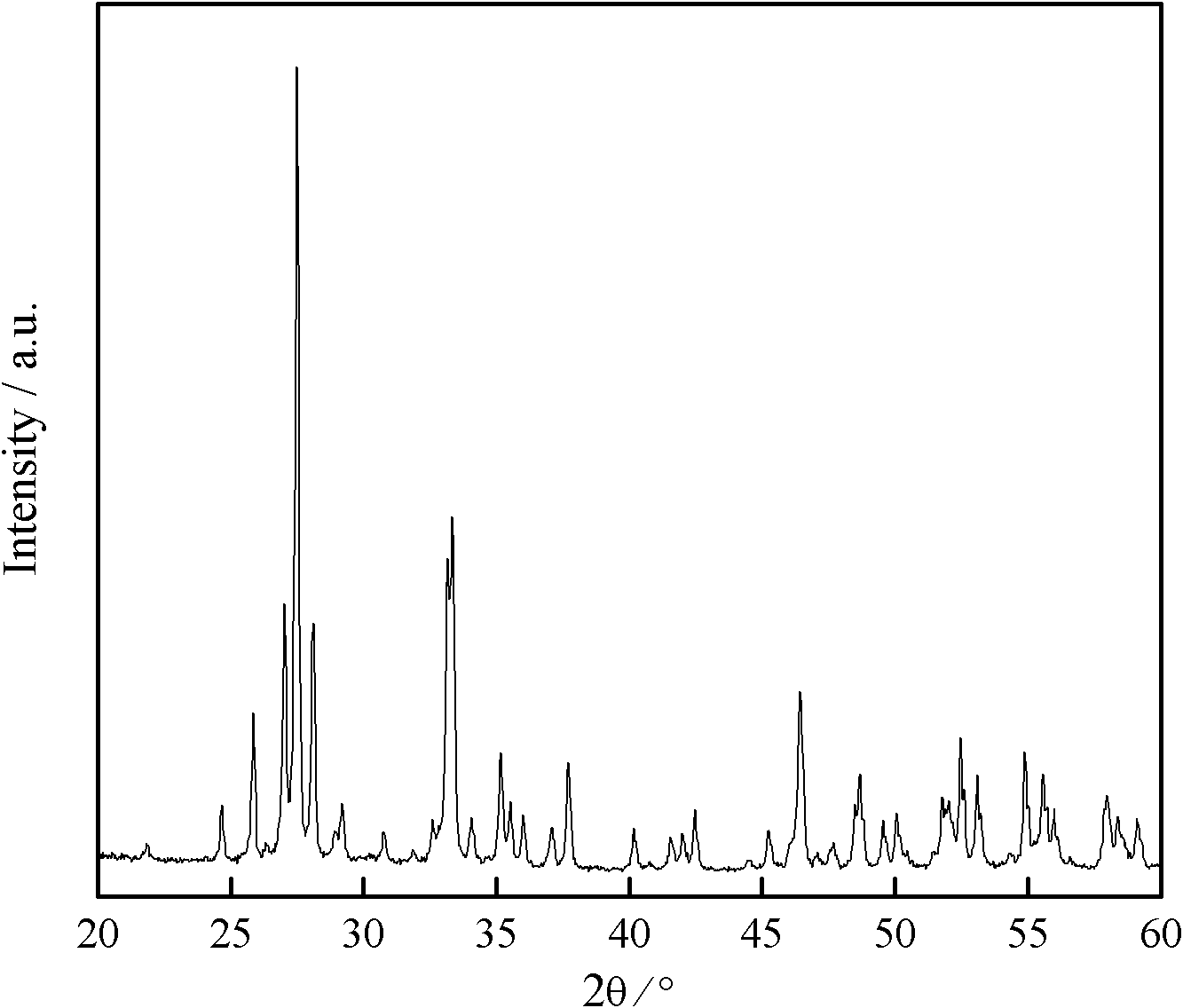

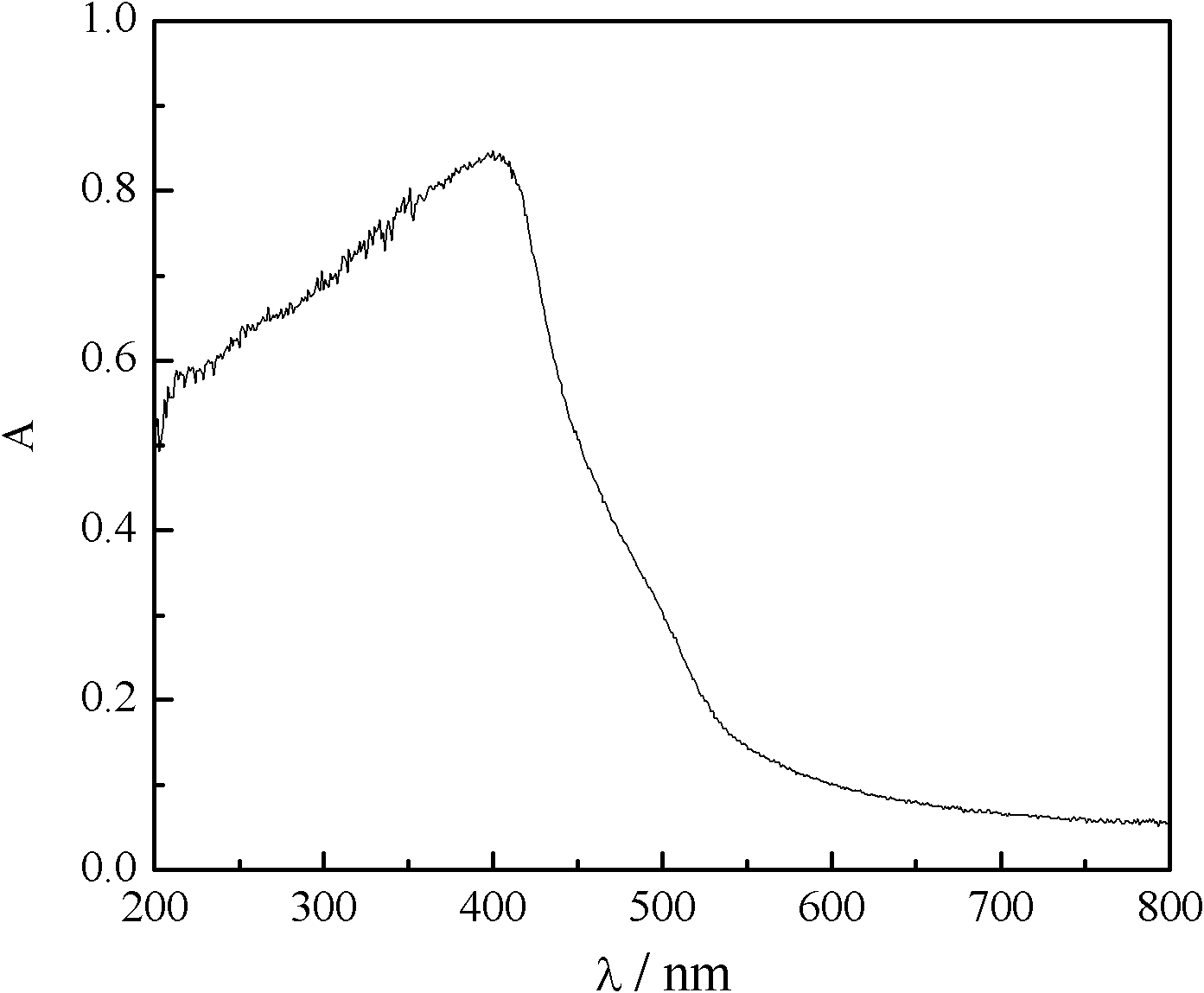

Embodiment 1

[0016] Weigh 9.799g of bismuth nitrate, add 4mL of concentrated nitric acid and 20mL of deionized water, stir and dissolve to obtain a bismuth nitrate solution. Weigh 2.385g of calcium nitrate, add 10mL of deionized water, stir and dissolve to obtain a calcium nitrate solution. Weigh 1.468g of EDTA, add 2mL of 35% ammonia water to dissolve to obtain EDTA solution. The calcium nitrate solution was then added dropwise to the bismuth nitrate solution with stirring, followed by the EDTA solution. Add 35% ammonia water dropwise to adjust the pH to 8 to form a white precipitate. Stir and age for 5 hours and filter with suction. The obtained solid is dried in an oven at 120°C for 12 hours, taken out and ground, and finally roasted in a muffle furnace at 500°C for 12 hours. Calcined CaBi at 500°C after natural cooling 7 o 11.5 catalyst.

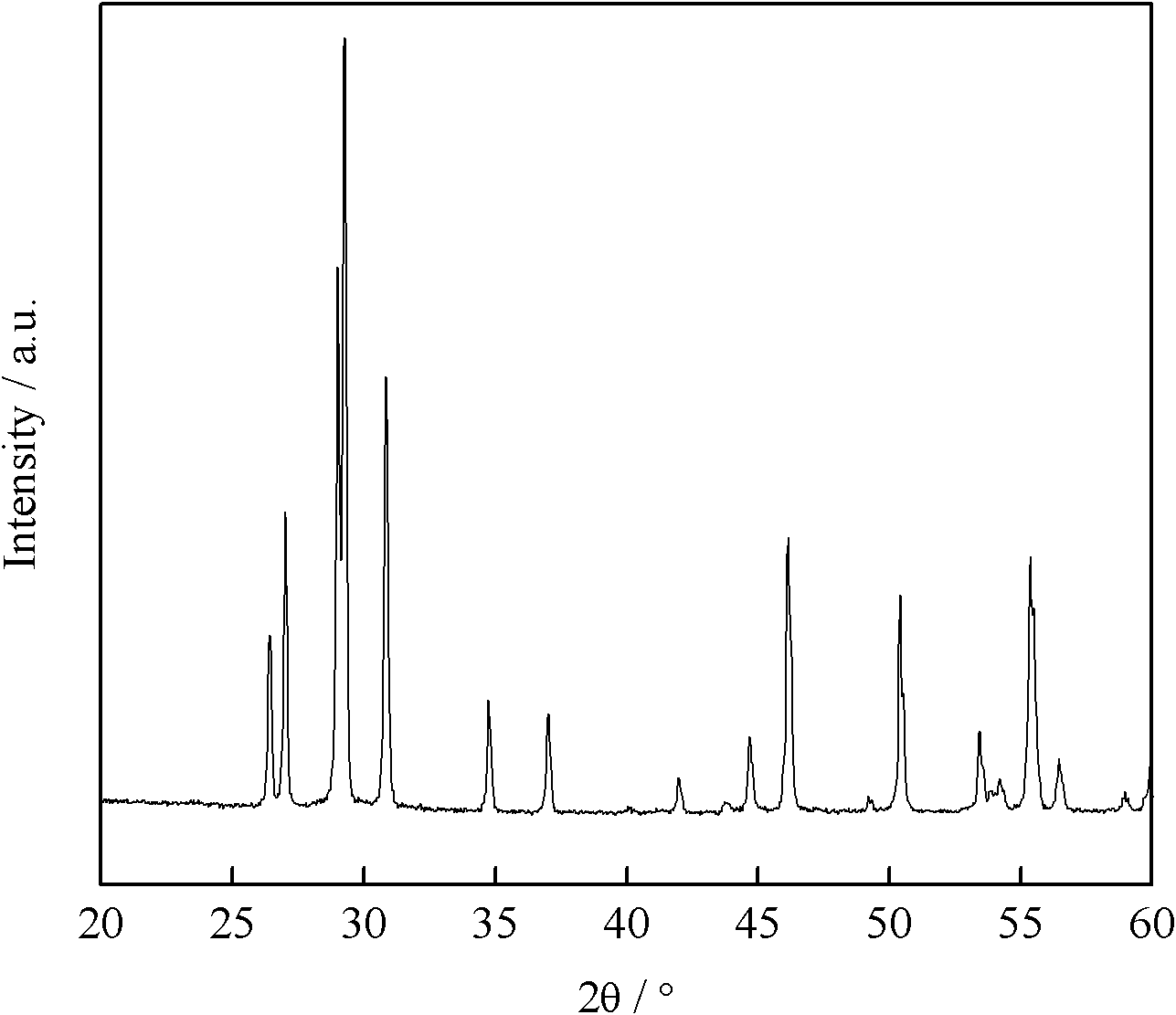

Embodiment 2

[0018] Weigh 9.799g of bismuth nitrate, add 4mL of concentrated nitric acid and 20mL of deionized water, stir and dissolve to obtain a bismuth nitrate solution. Weigh 2.385g of calcium nitrate, add 10mL of deionized water, stir and dissolve to obtain a calcium nitrate solution. Weigh 1.468g of EDTA, add 2mL of 35% ammonia water to dissolve to obtain EDTA solution. The calcium nitrate solution was then added dropwise to the bismuth nitrate solution with stirring, followed by the EDTA solution. Add 35% ammonia water dropwise to adjust the pH to 8 to form a white precipitate. Stir and age for 5 hours and filter with suction. The obtained solid is dried in an oven at 120°C for 12 hours, taken out and ground, and finally roasted in a muffle furnace at 550°C for 12 hours. Calcined CaBi at 550°C after natural cooling 7 o 11.5 catalyst.

Embodiment 3

[0020] Weigh 9.799g of bismuth nitrate, add 4mL of concentrated nitric acid and 20mL of deionized water, stir and dissolve to obtain a bismuth nitrate solution. Weigh 2.385g of calcium nitrate, add 10mL of deionized water, stir and dissolve to obtain a calcium nitrate solution. Weigh 1.468g of EDTA, add 2mL of 35% ammonia water to dissolve to obtain EDTA solution. The calcium nitrate solution was then added dropwise to the bismuth nitrate solution with stirring, followed by the EDTA solution. Add 35% ammonia water dropwise to adjust the pH to 8 to form a white precipitate. Stir and age for 5 hours and then suction filter. The obtained solid is dried in an oven at 120°C for 12 hours, taken out and ground, and finally roasted in a muffle furnace at 600°C for 12 hours. Calcined CaBi at 600°C after natural cooling 7 o 11.5 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com