Visible-light response calcium-bismuth composite oxide catalyst and preparation method thereof

A technology of composite oxides and catalysts, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Complicated process and other issues, to achieve high commercial application prospects, good visible light degradation activity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

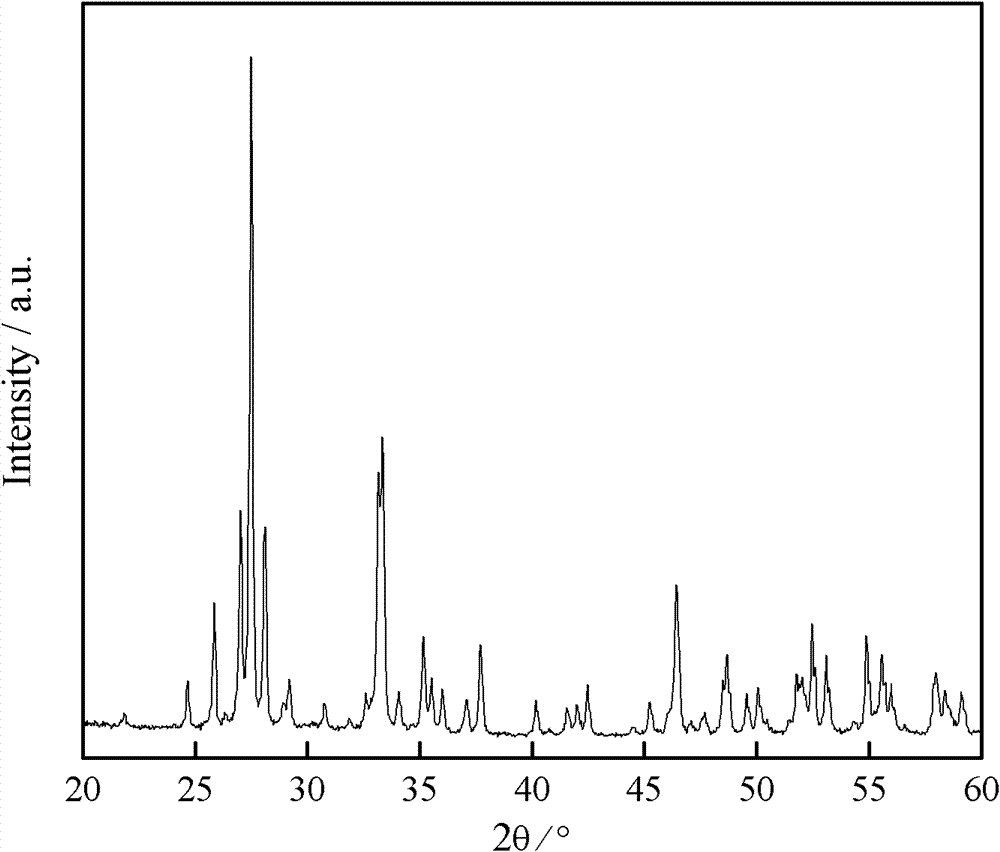

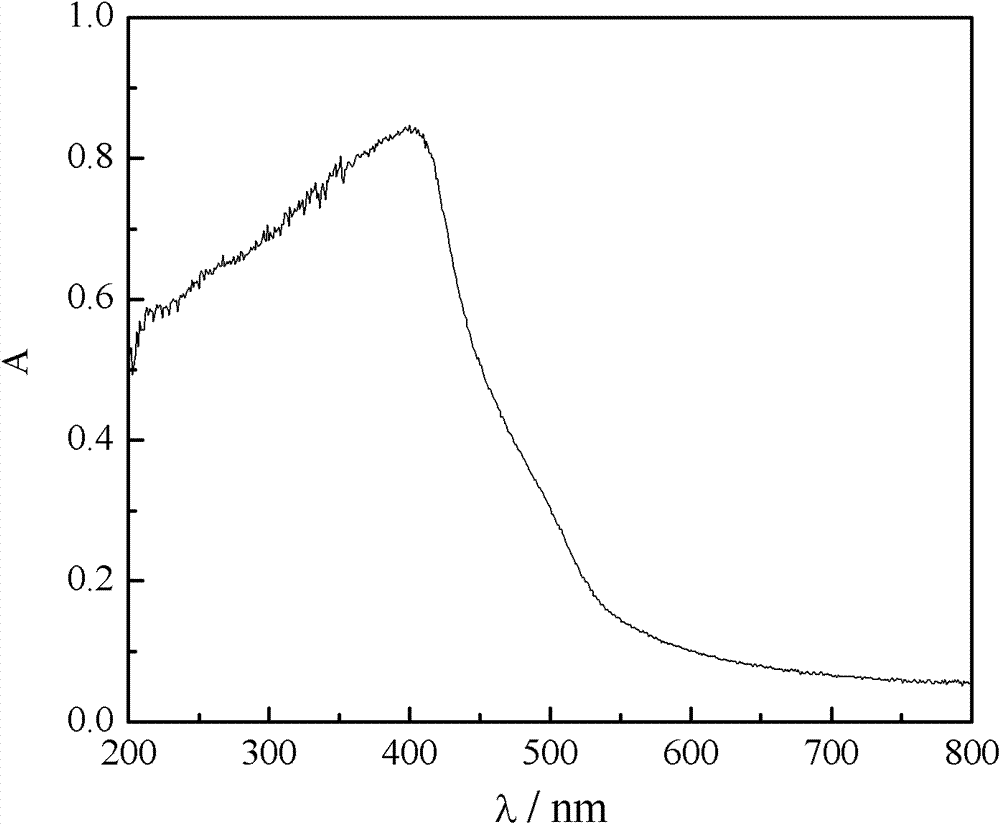

Embodiment 1

[0016] Weigh 9.799g of bismuth nitrate, add 4mL of concentrated nitric acid and 20mL of deionized water, stir and dissolve to obtain a bismuth nitrate solution. Weigh 2.385g of calcium nitrate, add 10mL of deionized water, stir and dissolve to obtain a calcium nitrate solution. Weigh 1.468g of EDTA, add 2mL of 35% ammonia water to dissolve to obtain EDTA solution. The calcium nitrate solution was then added dropwise to the bismuth nitrate solution with stirring, followed by the EDTA solution. Add 35% ammonia water dropwise to adjust the pH to 8 to form a white precipitate. Stir and age for 5 hours and filter with suction. The obtained solid is dried in an oven at 120°C for 12 hours, taken out and ground, and finally roasted in a muffle furnace at 500°C for 12 hours. Calcined CaBi at 500°C after natural cooling 7 o 11.5 catalyst.

Embodiment 2

[0018] Weigh 9.799g of bismuth nitrate, add 4mL of concentrated nitric acid and 20mL of deionized water, stir and dissolve to obtain a bismuth nitrate solution. Weigh 2.385g of calcium nitrate, add 10mL of deionized water, stir and dissolve to obtain a calcium nitrate solution. Weigh 1.468g of EDTA, add 2mL of 35% ammonia water to dissolve to obtain EDTA solution. The calcium nitrate solution was then added dropwise to the bismuth nitrate solution with stirring, followed by the EDTA solution. Add 35% ammonia water dropwise to adjust the pH to 8 to form a white precipitate. Stir and age for 5 hours and filter with suction. The obtained solid is dried in an oven at 120°C for 12 hours, taken out and ground, and finally roasted in a muffle furnace at 550°C for 12 hours. Calcined CaBi at 550°C after natural cooling 7 o 11.5 catalyst.

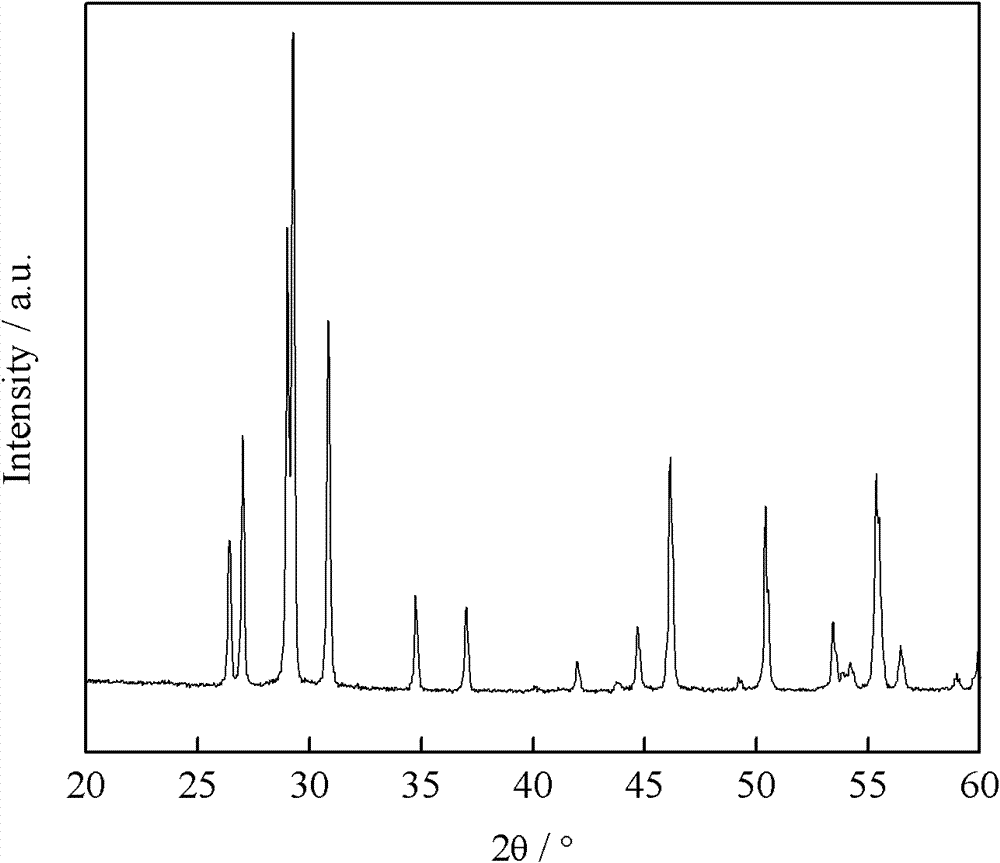

Embodiment 3

[0020] Weigh 9.799g of bismuth nitrate, add 4mL of concentrated nitric acid and 20mL of deionized water, stir and dissolve to obtain a bismuth nitrate solution. Weigh 2.385g of calcium nitrate, add 10mL of deionized water, stir and dissolve to obtain a calcium nitrate solution. Weigh 1.468g of EDTA, add 2mL of 35% ammonia water to dissolve to obtain EDTA solution. The calcium nitrate solution was then added dropwise to the bismuth nitrate solution with stirring, followed by the EDTA solution. Add 35% ammonia water dropwise to adjust the pH to 8 to form a white precipitate. Stir and age for 5 hours and then suction filter. The obtained solid is dried in an oven at 120°C for 12 hours, taken out and ground, and finally roasted in a muffle furnace at 600°C for 12 hours. Calcined CaBi at 600°C after natural cooling 7 o 11.5 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com