Method for treating domestic garbage

A technology of domestic waste and treatment method, which is applied in the field of domestic waste treatment to achieve the effect of low cost, high recovery rate and high income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

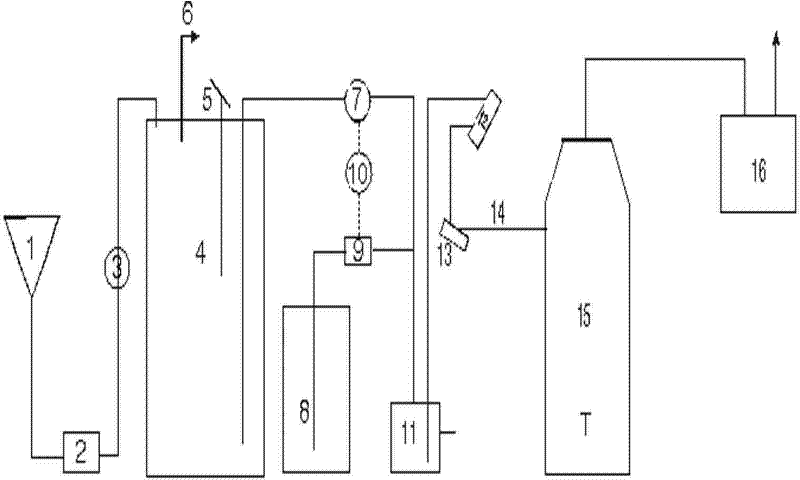

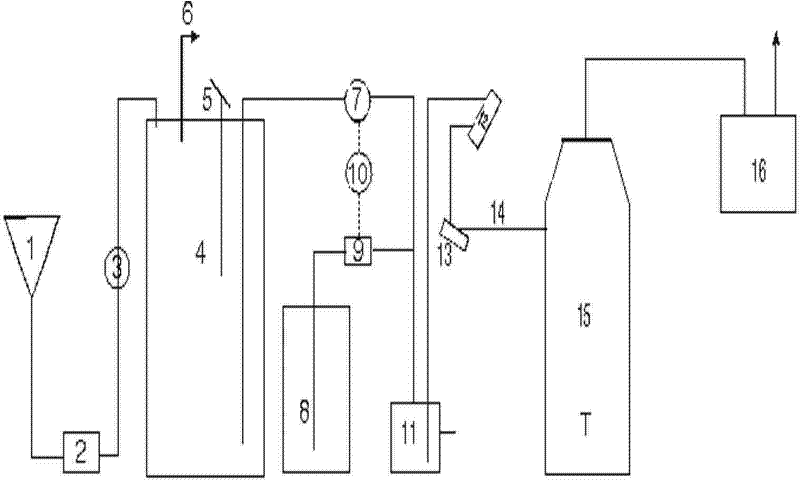

[0016] The domestic waste processed in this embodiment is kitchen waste, and the dry powder is diatomaceous earth powder. The food waste disposal method includes the following steps:

[0017] (1) Homogenization: send the garbage to the homogenizer through the feeding port 1 for homogenization treatment to 50 meshes;

[0018] (2) Fermentation: The homogenized food waste is sent to the fermentor 4 through the slurry pump 3 for anaerobic fermentation. The fermentor 4 is equipped with a solar heat conduction tube 5 to heat the fermenter, and ferment at 20°C. Today, the biogas produced during fermentation is sent to the living area for lighting or as a life heat source through the biogas exhaust pipe 6 located on the top of the tank, and the excess biogas is sent to the kiln 15 to be burned into ceramsite with mud balls;

[0019] (3) Mixing into mud ball: the fermented garbage mixture is pumped into the pre-mixing tank 11 through the limited pump 7; the diatomaceous earth powder in the d...

Embodiment 2

[0022] The domestic waste processed in this embodiment is kitchen waste, and the dry powder is lime powder. The food waste disposal method includes the following steps:

[0023] (1) Homogenization: send the garbage to the homogenizer through the feeding port 1 for homogenization treatment to 100 meshes;

[0024] (2) Fermentation: The homogenized food waste is sent to the fermentor 4 through the slurry pump 3 for anaerobic fermentation. The fermentor 4 is equipped with a solar heat conduction tube 5 to heat the fermenter and ferment at 28°C. Today, the biogas produced during fermentation is sent to the living area for lighting or as a life heat source through the biogas exhaust pipe 6 located on the top of the tank, and the excess biogas is sent to the kiln 15 to be burned into ceramsite with mud balls;

[0025] (3) Mixing into mud ball: the fermented garbage mixture is pumped into the pre-mixing tank 11 through the limited pump 7; the diatomaceous earth powder in the dry powder tank...

Embodiment 3

[0028] The domestic waste processed in this embodiment is kitchen waste, and the dry powder is a mixture of limestone powder and diatomaceous earth powder, and the weight ratio of the two is 1:1. The food waste disposal method includes the following steps:

[0029] (1) Homogenization: send the garbage to the homogenizer through the feeding port 1 for homogenization treatment to 200 meshes;

[0030] (2) Fermentation: The homogenized food waste is sent to the fermentor 4 through the slurry pump 3 for anaerobic fermentation. The fermenter 4 is equipped with a solar heat pipe 5 to heat the fermenter and ferment at 35°C 10 Today, the biogas produced during fermentation is sent to the living area for lighting or as a life heat source through the biogas exhaust pipe 6 located on the top of the tank, and the excess biogas is sent to the kiln 15 to be burned into ceramsite with mud balls;

[0031] (3) Mixing into mud ball: the fermented garbage mixture is pumped into the pre-mixing tank 11 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com