Method for efficiently denitriding aerobic granular sludge by combining stepwise water feeding with alternate anaerobic and aerobic treatment

An aerobic granular sludge, anaerobic and aerobic technology, applied in water/sludge/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. High cost and other issues, to achieve the effect of broadening the scope of application, improving the optimization of utilization, and increasing the nitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Treatment of carbon and nitrogen (COD∶NH 4 + -N) Synthetic waste water with a ratio of 10.

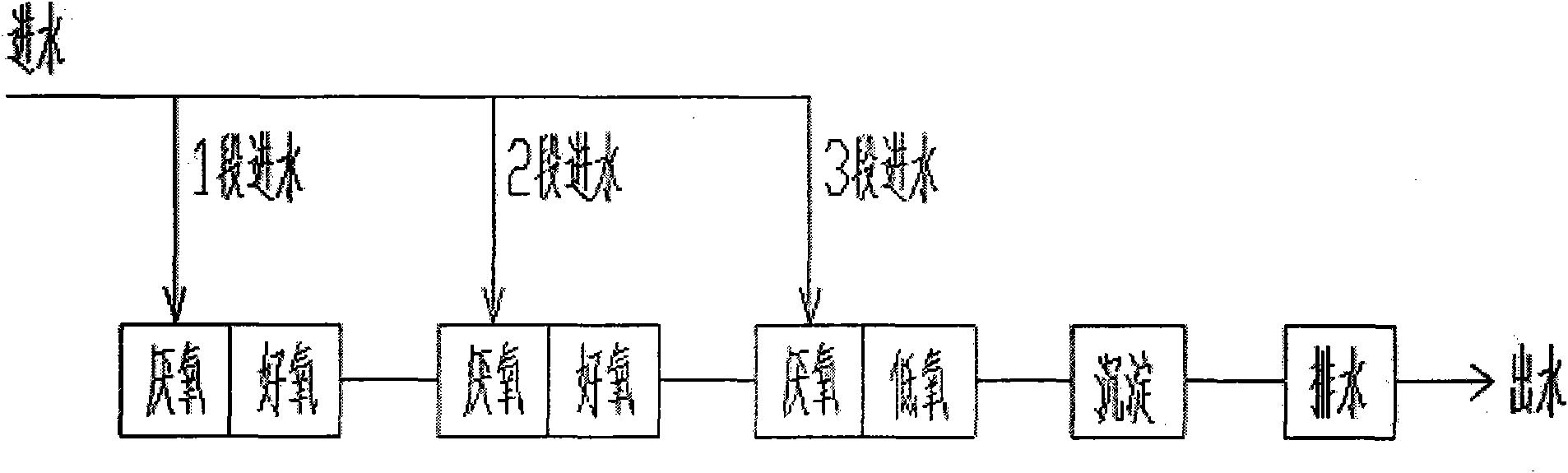

[0032] Adopt the aerobic granular sludge high-efficiency denitrification method of the present invention to carry out wastewater treatment, and the whole operation period is 6 hours; wherein, the three-stage anaerobic stage is set to 30 minutes respectively; the first and second stage aerobic stages are respectively set to 60 minutes; the low oxygen stage (low dissolved oxygen stage) is set to 143 minutes, the precipitation stage is set to 2 minutes, and the drainage stage is set to 5 minutes.

[0033] After adopting the aerobic particle denitrification treatment, the nitrogen removal efficiency is 93%; wherein, the average particle diameter of the particles is 1.5 mm.

Embodiment 2

[0035] Treatment of carbon and nitrogen (COD∶NH 4 + -N) ratio of 5 synthetic waste water.

[0036] The aerobic granular sludge high-efficiency denitrification method of the present invention is used for wastewater treatment, and the entire operation period is 6 hours; wherein, the three anaerobic stages are respectively set to 30 minutes; the first and second aerobic stages are respectively set to 70 minutes and 50 minutes; the low oxygen stage (low dissolved oxygen stage) is set to 143 minutes, the precipitation stage is set to 2 minutes, and the drainage stage is set to 5 minutes.

[0037] After being treated by the denitrification system, the nitrogen removal efficiency is 96%; wherein, the average particle diameter of the particles is 1.3 mm.

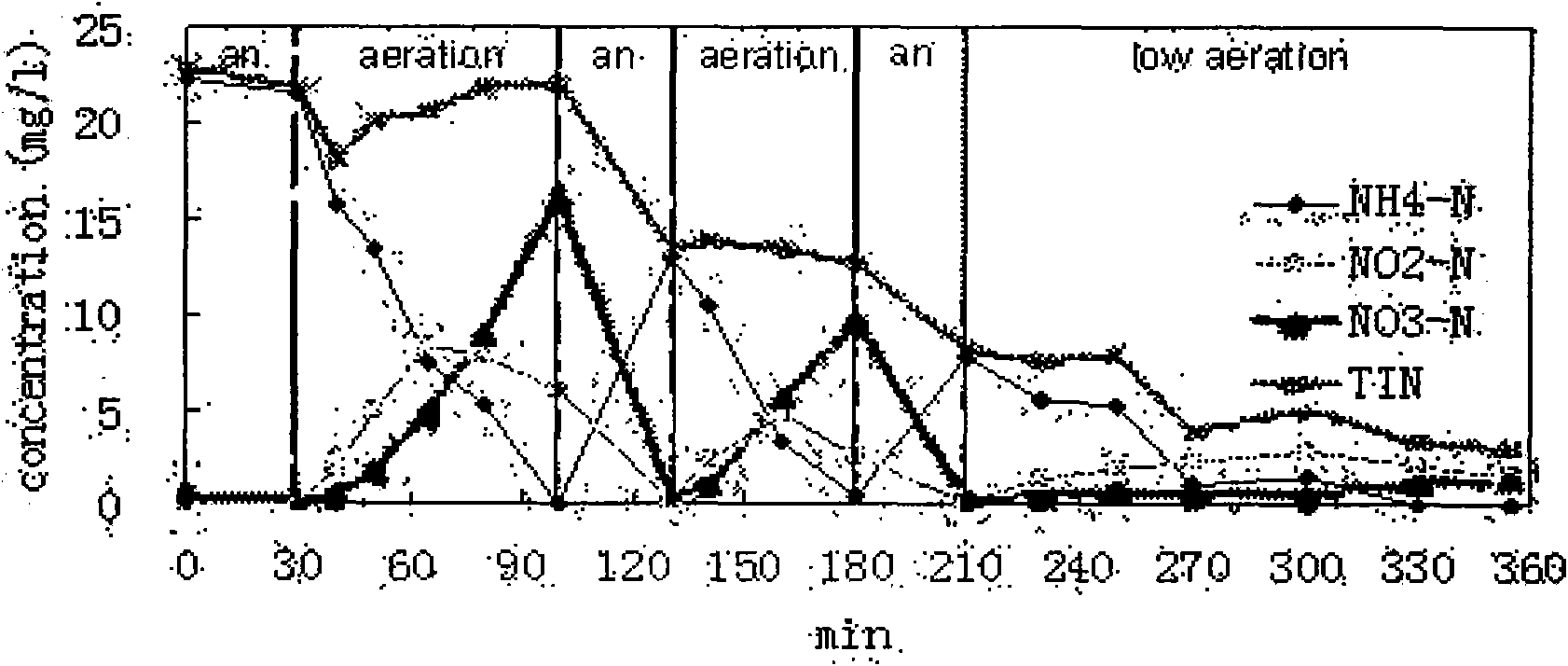

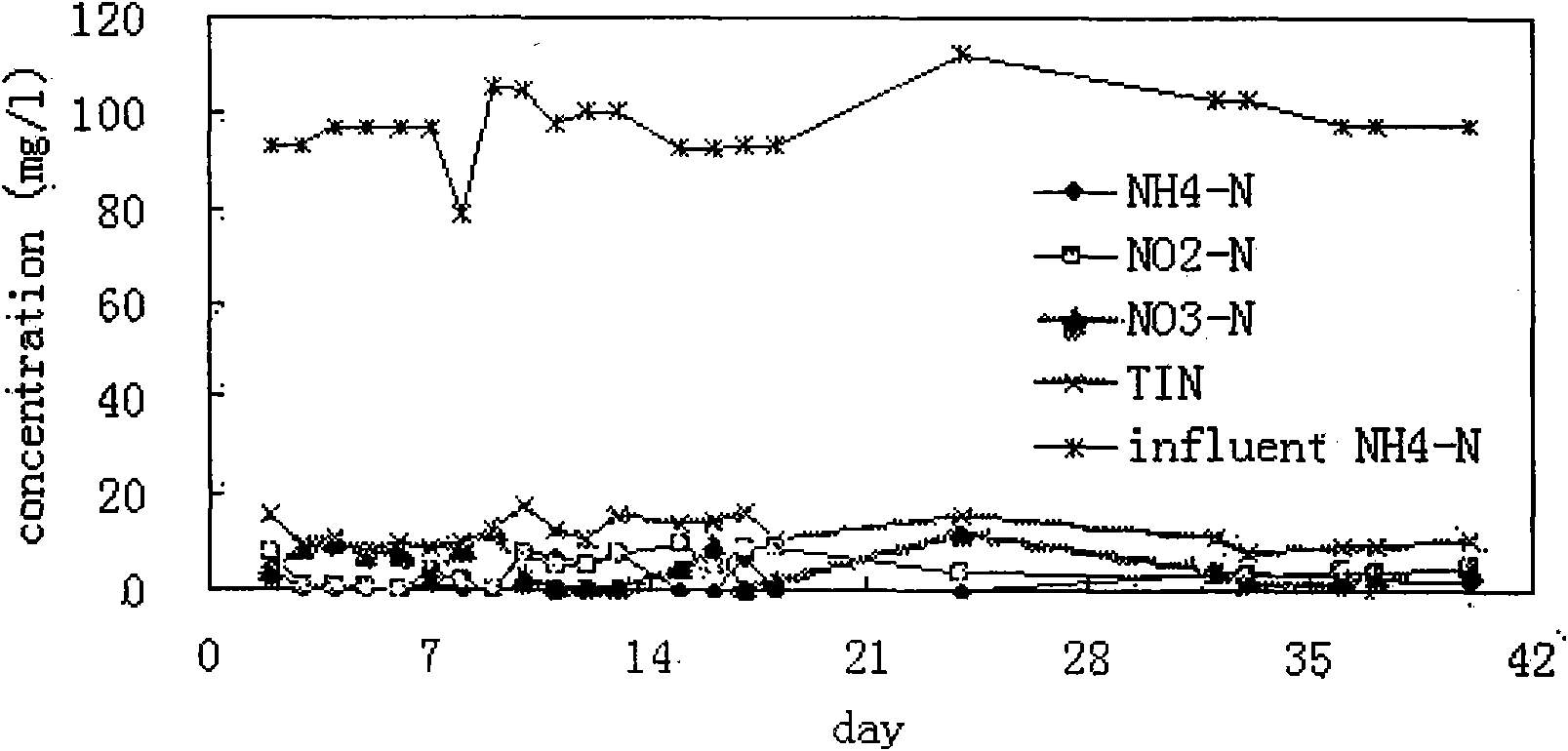

[0038] The typical nitrogen removal situation in the operation cycle in this example is as follows figure 2 As shown, the nitrogen removal conditions during the medium and long-term operation period are as follows image 3 show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com