Composite stabilizing agent for transparent polyvinyl chloride (PVC) material and preparation method thereof

A composite stabilizer and main stabilizer technology, applied in the chemical industry, can solve the problem of high cost, achieve the effect of improving thermal stability, reducing production cost, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

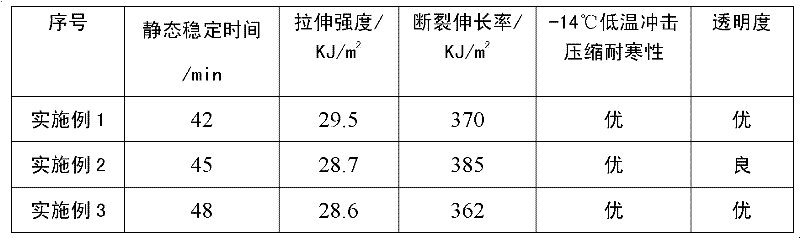

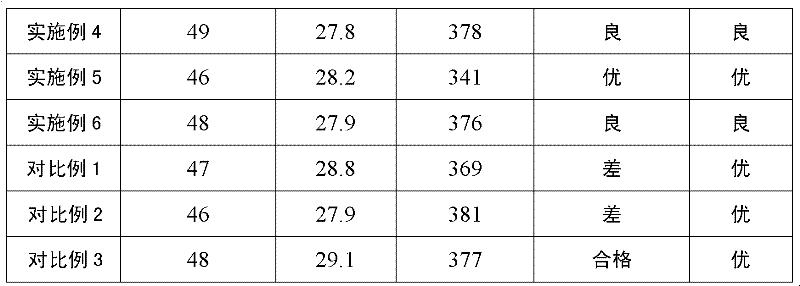

Examples

Embodiment 1

[0016] Prepare the composite stabilizer for transparent PVC according to the following formula and method:

[0017] Formula: main stabilizer: methyl tin mercaptide, 78 parts, lanthanum stearate, 5 parts; auxiliary stabilizer: monophenylenedioctyl phosphite, 4 parts, epoxy soybean oil, 10 parts and mass ratio 1 : 1 part of β-diketone compound formed by mixing rigid benzoylmethane and benzoylmethane, 3 parts; emulsifier: OP-10, 1 part; defoamer: tributyl phosphate, 0.1 part .

[0018] Preparation method: add methyl tin mercaptide, 78 parts, lanthanum stearate, 5 parts and OP-10, 1 part into the reaction kettle and stir, control the stirring speed at 200-500r / min, when the temperature rises to 70-80 At ℃, add phenylenedioctyl phosphite, 4 parts, epoxidized soybean oil, 10 parts and β-diketone mixed with rigid benzoylmethane and benzoylmethane in a mass ratio of 1:1 3 parts of similar compound, 0.1 part of tributyl phosphate was added during the stirring process, stirred for 50-...

Embodiment 2

[0020] Except that the organotin compound is changed to butyltin mercaptide, the others are the same as in Example 1.

Embodiment 3

[0022] Except that the organotin compound was changed to dibutyltin dilaurate, the others were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com