Transfer plate with metal vertical interconnection structure and manufacture method thereof

A technology of vertical interconnection and manufacturing method, applied in the field of three-dimensional stacking, can solve the problems of complex process and high cost of manufacturing three-dimensional stacked chips, and achieve the effects of simplified process steps, simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

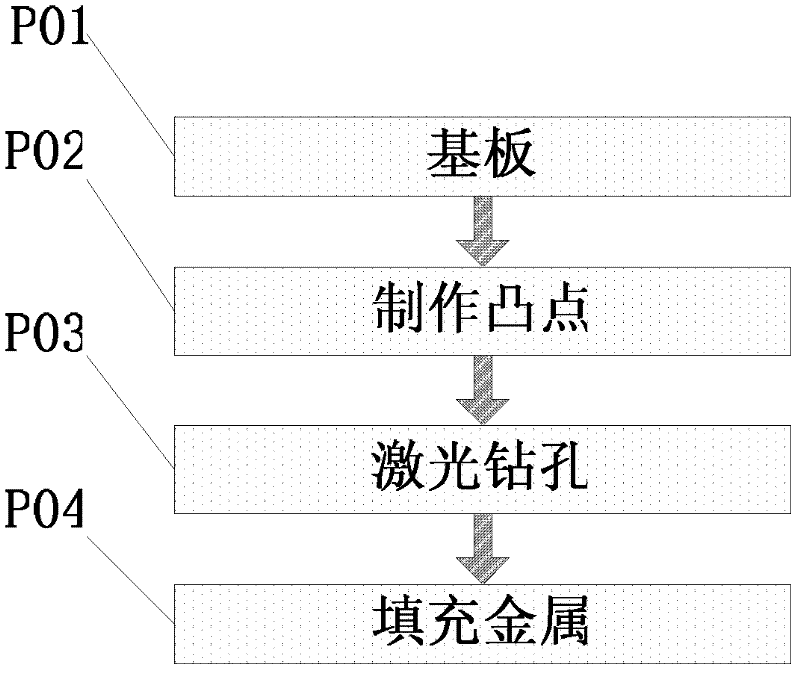

Method used

Image

Examples

Embodiment 1

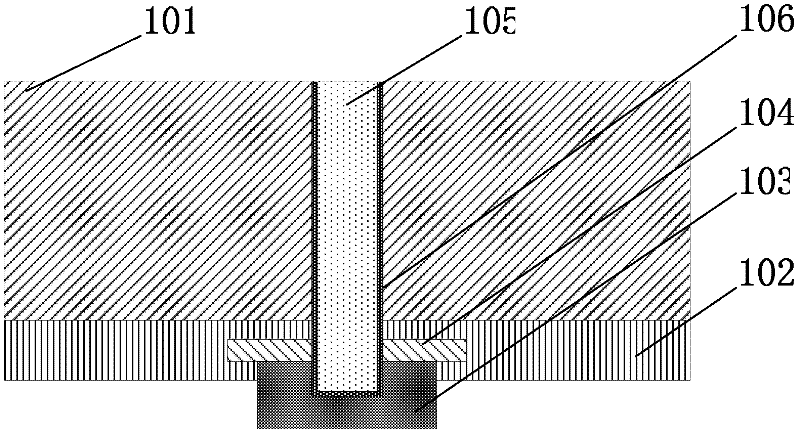

[0044] First, refer to figure 1 Embodiment 1 of the metal vertical interconnection structure applied to three-dimensional stacked chips disclosed in the present invention will be introduced. This Embodiment 1 is a specific structure when the present invention is applied to an interposer.

[0045] in such as figure 1 The shown interposer structure includes a substrate 101 . In this embodiment, the material of the substrate 101 is glass, but it may also be silicon or organic material. There is a passivation layer 102 on the lower surface of the substrate 101 . The material of the passivation layer 102 is polyimide in this embodiment. There is a metal bump structure on the lower surface side of the passivation layer 102, the metal bump structure includes a pad 104, which is buried inside the passivation layer 102, and a metal bump 103 is arranged on the lower surface of the pad 104 . In this embodiment, the pad 104 is made of metal aluminum. In this embodiment, the materia...

Embodiment 2

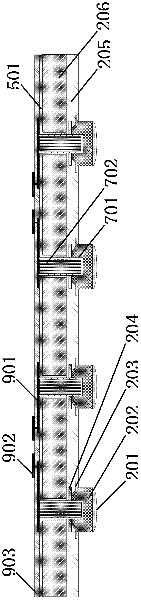

[0055] image 3 A metal vertical interconnection structure applied to three-dimensional stacked chips according to Embodiment 2 of the present invention is depicted. Specifically, this second embodiment is also a specific structure when the present invention is applied to an interposer.

[0056] in such as image 3 In the illustrated interposer, a substrate 206 is included. In Example 2, the substrate 206 is a 4-inch silicon wafer with a thickness of 200 microns. Optionally, the material of the substrate 206 may also be glass or organic material. On the lower surface of the substrate 206 there is a passivation layer 205 . There is a metal bump structure in the passivation layer 205 , a part of the metal bump structure is embedded in the passivation layer 205 , and another part protrudes from the lower surface of the passivation layer 205 .

[0057] Specifically, the metal bump structure includes pads 204 , underlying metal layer 203 , metal pillars 202 and solder 201 . W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com