Germanium-silicon heterojunction bipolar transistor and manufacturing method thereof

A heterojunction bipolar and transistor technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of high R&D cost of advanced technology, difficulty in realizing characteristic frequency, and toxicity of compound semiconductors, etc., to achieve inhibition Current collector effect, increase BVCEO, reduce the effect of collector resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

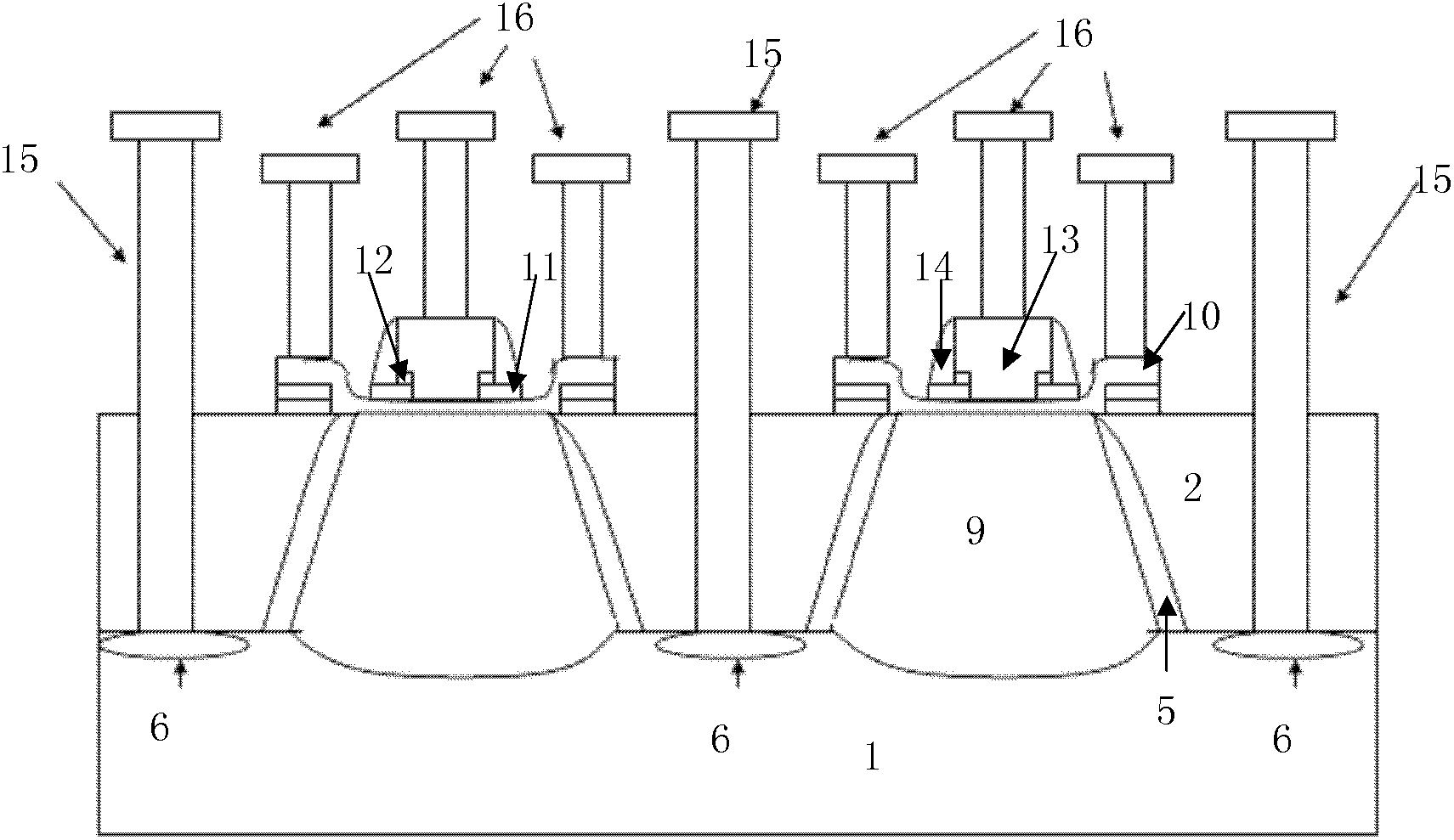

[0044] Such as figure 1 Shown is a schematic diagram of the structure of a germanium-silicon heterojunction bipolar transistor according to an embodiment of the present invention. The germanium-silicon heterojunction bipolar transistor in the embodiment of the present invention is formed on a P-type silicon substrate 1, and the isolation structure of the active region is a shallow trench isolation 2. The germanium-silicon heterojunction bipolar transistor includes:

[0045] A collector region 9 is composed of an N-type ion implantation region formed in the active region, and the depth of the collector region 9 is greater than the depth of the bottom of the shallow trench isolation 2 .

[0046] A pseudo-buried layer (NBL) 6, composed of arsenic ion implantation regions formed at the bottom of the shallow trench isolation 2 on both sides of the active region, the pseudo-buried layer 6 extends into the active region and connects with the The collector region 9 is in contact with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com