Ultrasound, magnetic field, pulse electrocoagulation and membrane composite waste water treatment method, and apparatus thereof

A pulsed electric and membrane composite technology, applied in the field of ultrasonic, pulsed electric flocculation and membrane composite technology to treat wastewater and magnetic field, can solve the problems of fast decline rate of membrane flux, shortened replacement cycle, high investment cost, etc., and achieves good clarification effect. , reduce energy consumption, the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

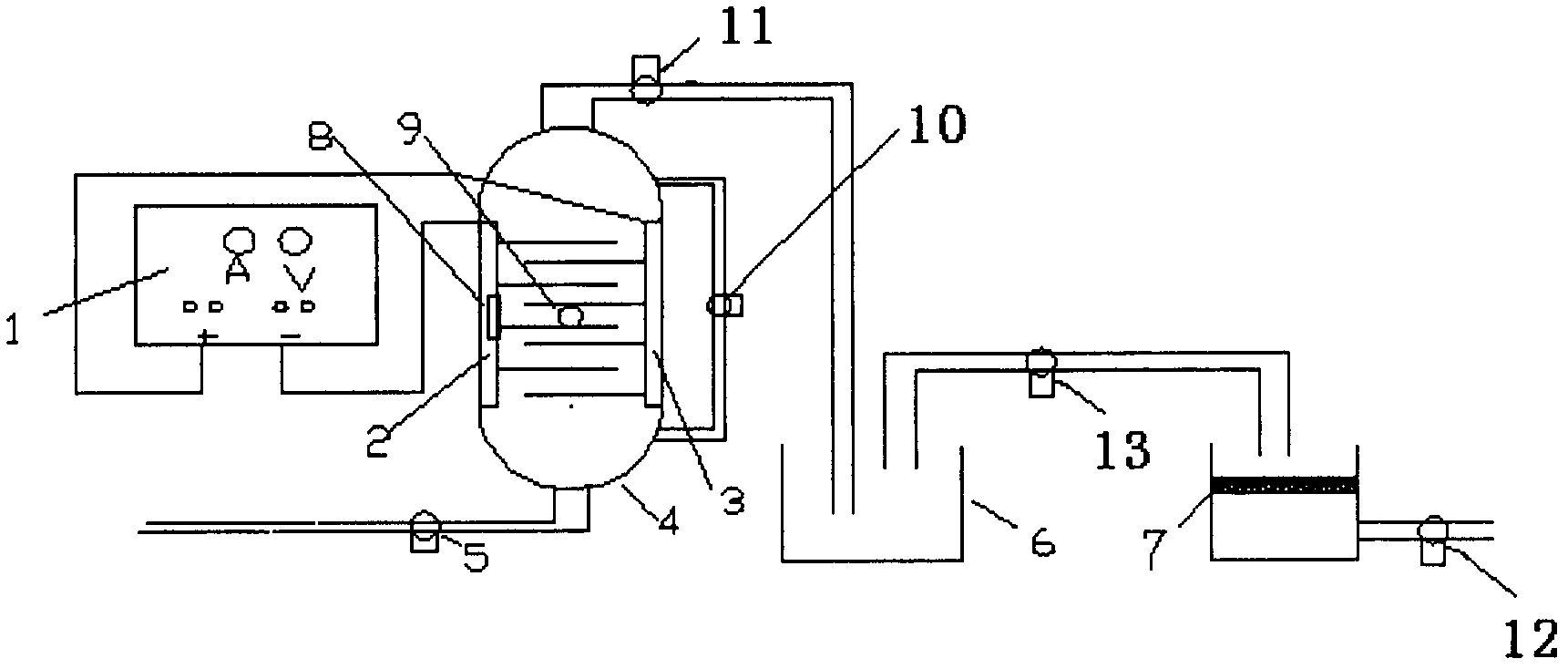

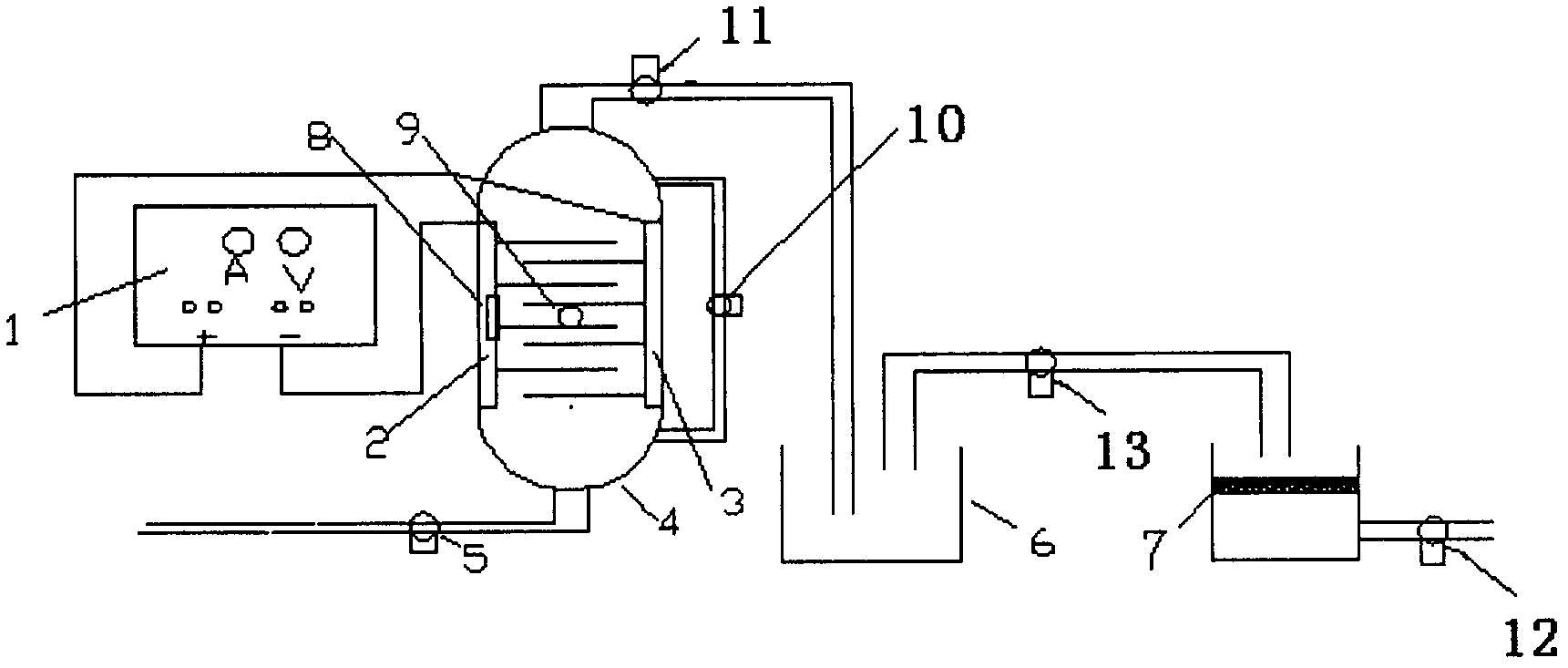

[0035] Dealing with heavy metals containing Cr 6+ Wastewater, the treatment process conditions of electrocoagulation reactor 4 are: electrocoagulation voltage: 6V, current: 38A, electrocoagulation treatment time 5min, ultrasonic frequency: 20KHZ, ultrasonic power: 100W, magnetic field strength 0.1T, 4 sets of electrode plates arranged in parallel , the distance between the electrode plates is 3.0cm, the anode is made of iron plate, the cathode is made of aluminum plate, when Cr 6+ When the concentration is about 50g / L, after being treated by the device of the present invention, the heavy metal Cr 6+ The removal rate was 98%. The electrode dissolution time was extended by 19%, and the electrode passivation time was extended by 26%.

Embodiment 2

[0037] Dealing with heavy metals containing Zn 2+ 、Cu 2+ 、Cr 6+ Wastewater, electrocoagulation reactor 4 treatment process conditions are: electrocoagulation voltage: 27V, current: 8A, electrocoagulation treatment time 12min, ultrasonic frequency: 40KHZ, ultrasonic power: 400W, magnetic field strength 0.2T, 4 sets of electrode plates arranged in parallel , the distance between the electrode plates is 3.0cm, the anode is made of iron plate, the cathode is made of aluminum plate, when Zn 2+ 、Cu 2+ 、Cr 6+ When the concentration is about 20g / L, after being treated by the device of the present invention, the heavy metal Zn 2+ 、Cu 2+ 、Cr 6+ The removal rates were 92%, 95%, and 96%, respectively. The electrode dissolution time was extended by 18%, and the electrode passivation time was extended by 23%.

Embodiment 3

[0039] To treat papermaking wastewater, the treatment process conditions of electrocoagulation reactor 4 are: electrocoagulation voltage: 5V, current: 15A, electrocoagulation treatment time 5min, ultrasonic frequency: 40KHZ, ultrasonic power: 300W, magnetic field strength 0.3T, 4 groups arranged in parallel Electrode plates, the distance between the electrode plates is 3.0cm, the anode adopts an iron plate, and the cathode adopts an aluminum plate. When the influent CODcr is at 400mg / L and AOX is at about 6mg / kg slurry, after the waste water is treated by the device of the present invention, CODcr, AOX The removal rates were 92% and 88%, respectively. The electrode dissolution time was extended by 20%, and the electrode passivation time was extended by 28%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com