Preparation method of wide-spectrum and strong-absorption surface-photovoltage type photodetector

A photodetector and photovoltaic technology, which is applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as limited spectral range, complex structure, and limited application range, and achieve broad application prospects and low production costs. Low, wide spectral range effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0029] A specific embodiment of the present invention is: a preparation method of a broad-spectrum, strong-absorbing surface photovoltaic photodetector, the specific method of which is:

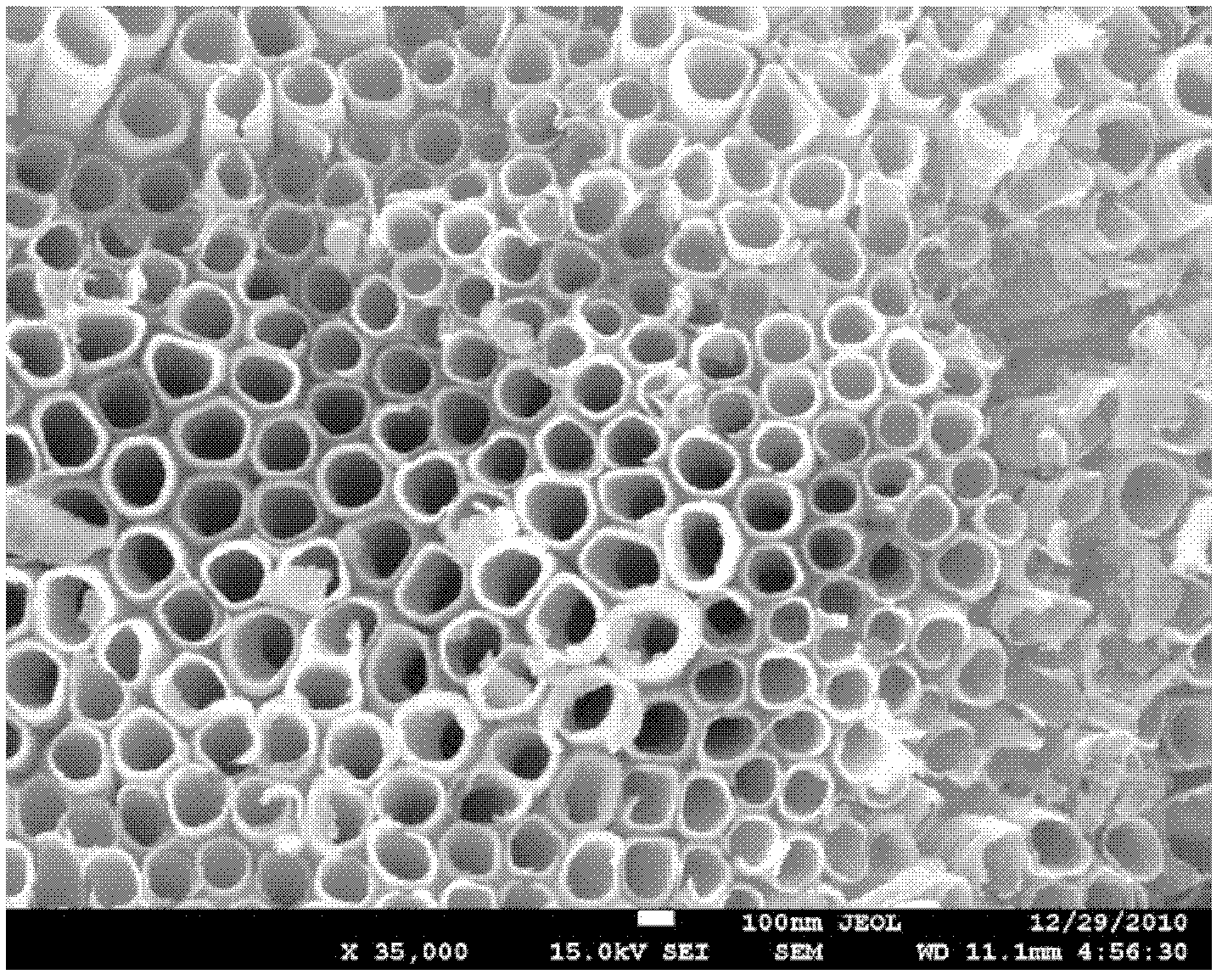

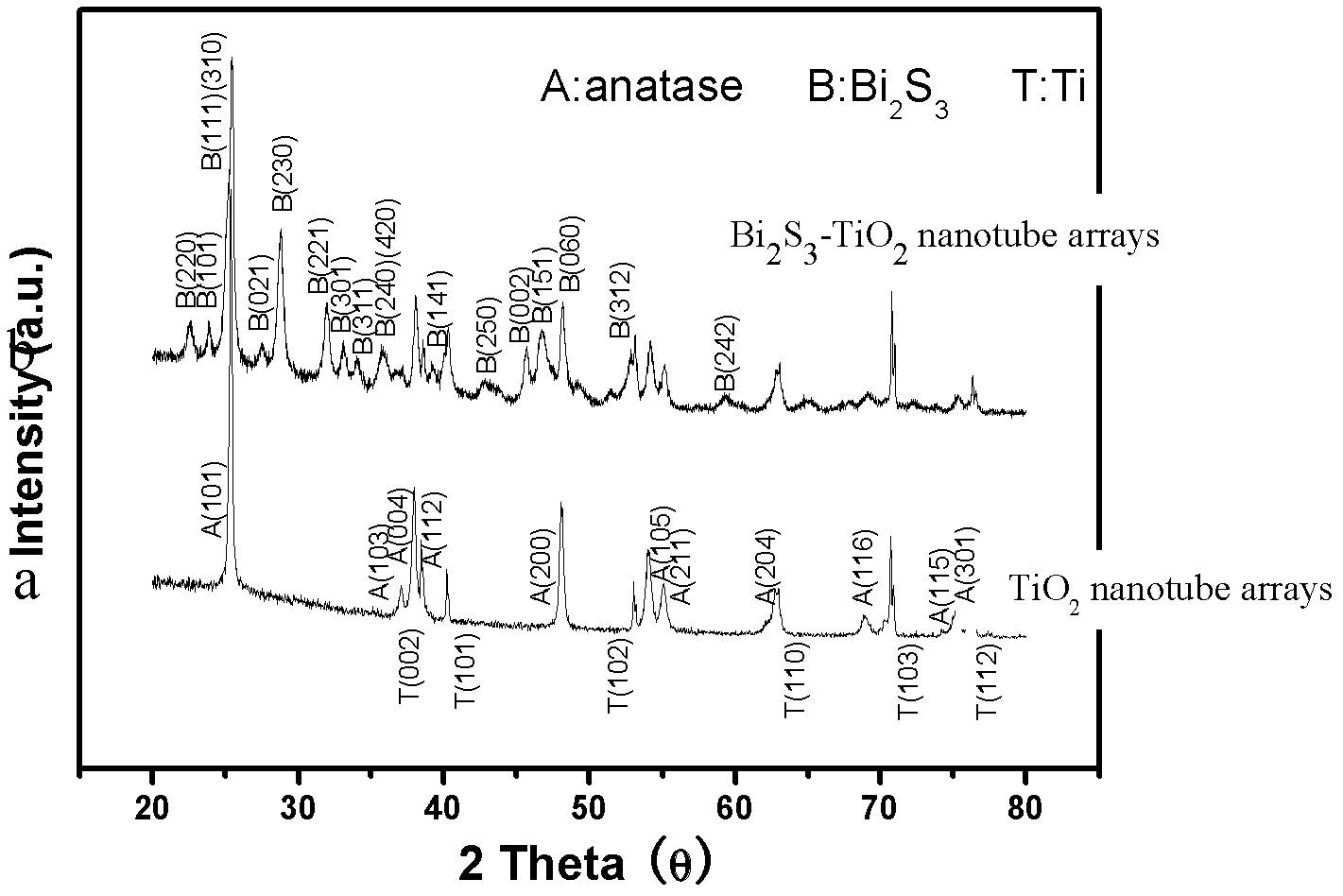

[0030] a. TiO 2 Fabrication and Crystallization of Nanotube Arrays

[0031] With titanium foil as anode, platinum as cathode, 0.25wt% NH 4 The ethylene glycol solution of F is the electrolyte, and the titanium foil is anodized for 3 hours; the titanium foil is taken out, rinsed with deionized water, and ultrasonically treated for 5 minutes to obtain amorphous TiO on the titanium foil. 2 nanotube arrays;

[0032] Titanium foil and its amorphous TiO 2 The nanotube array was heated up to 450°C at a rate of 3°C / min, held for 3 hours and annealed for 3 hours, and finally cooled to room temperature with the furnace, that is, anatase TiO was formed on the titanium foil immersed in the electrolyte. 2 Nanotube array, no product attached to the part of the titanium foil that is not immersed in the ...

Embodiment 2

[0046] The specific approach in this example is

[0047] a. TiO 2 Fabrication and Crystallization of Nanotube Arrays

[0048] With titanium foil as anode, platinum as cathode, 0.25wt% NH 4 The ethylene glycol solution of F is the electrolyte, and the titanium foil is anodized for 6 hours; the titanium foil is taken out, rinsed with deionized water, and ultrasonically treated for 8 minutes to obtain amorphous TiO on the titanium foil. 2 nanotube arrays;

[0049] Titanium foil and its amorphous TiO 2 The nanotube array is heated up to 450°C at a rate of 20°C / min, held for 3.5 hours, and finally cooled to room temperature with the furnace, that is, anatase TiO is formed on the titanium foil immersed in the electrolyte. 2 Nanotube array, no product attached to the part of the titanium foil that is not immersed in the electrolyte;

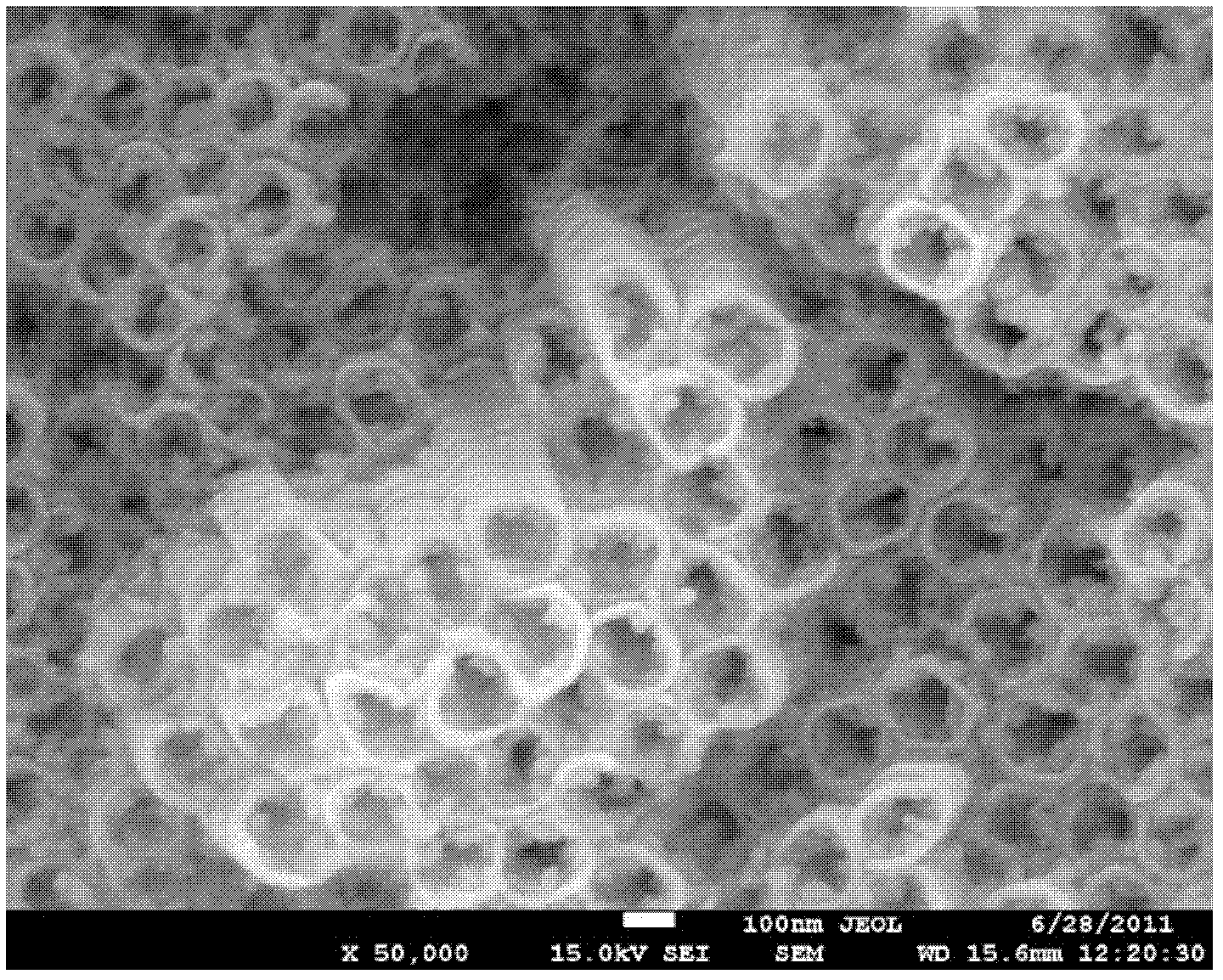

[0050] b. Preparation of Bi by hydrothermal method 2 S 3 -TiO 2 nanotube array

[0051] Na 2 S 2 o 3 Added to 0.008mol / L Bi(NO 3 ) 3 The ...

Embodiment 3

[0058] The specific approach in this example is

[0059] a. TiO 2 Fabrication and Crystallization of Nanotube Arrays

[0060] With titanium foil as anode, platinum as cathode, 0.25wt% NH 4 The ethylene glycol solution of F is the electrolyte, and the titanium foil is anodized for 5 hours; the titanium foil is taken out, rinsed with deionized water, and ultrasonically treated for 6 minutes to obtain amorphous TiO on the titanium foil. 2 nanotube arrays;

[0061] Titanium foil and its amorphous TiO 2 The nanotube array was heated to 450°C at a rate of 10°C / min, held for 4 hours, and finally cooled to room temperature with the furnace, that is, anatase TiO was formed on the titanium foil immersed in the electrolyte. 2 Nanotube array, no product attached to the part of the titanium foil that is not immersed in the electrolyte;

[0062] b. Preparation of Bi by hydrothermal method 2 S 3 -TiO 2 nanotube array

[0063] Na 2 S 2 o 3 Added to 0.009mol / L Bi(NO 3 )3 The react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com