Multi-element piezoelectric composite material and preparation method and application thereof

A piezoelectric composite material and composite material technology, applied in the field of piezoelectric composite materials and their preparation, can solve the problems of complex transducer array methods, waste of raw materials, difficult operation, etc., achieve broad application prospects, simple and consistent preparation process good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

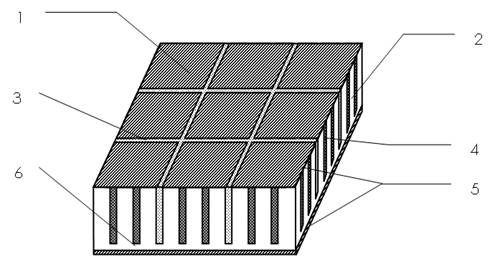

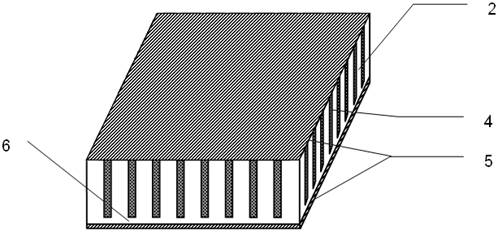

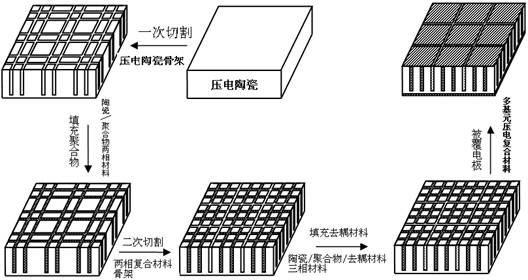

Embodiment 1

[0063] Using PZT4 piezoelectric ceramic sheet, piezoelectric constant d 33 210pC·N -1 , the electromechanical coupling coefficient K t 49.67%, mechanical quality factor Q m is 48.6, relative permittivity ε r 999, the material thickness is 15.1mm. The polymer adopts epoxy resin with good fluidity (AB grouting resin), and the ratio of epoxy resin to curing agent is 4:1. The decoupling material is HL-2288 silica gel, the filling width is 0.5mm, and the ratio of silica gel to curing agent is 1:0.02. According to the above-mentioned preparation process, the number of primitives is 6 (3×2), and the number of ceramic pillars in each primitive is 9 (3×3). The cross-sectional size of each ceramic pillar is 1.5mm×1.5mm, and the height of the ceramic pillar is The performance of the obtained multi-element piezoelectric composite material is as follows:

[0064] (1) Piezoelectric, dielectric and electromechanical coupling properties

[0065] Table 1 shows the piezoelectric, ...

Embodiment 2

[0073] Using PZT4 piezoelectric ceramic sheet, piezoelectric constant d 33 210pC·N -1 , the electromechanical coupling coefficient K t 49.67%, mechanical quality factor Q m is 48.6, relative permittivity ε r 999, the material thickness is 15.1mm. The polymer adopts epoxy resin (AB grouting resin) with good fluidity, and the mass ratio of epoxy resin to curing agent is 4:1. The decoupling material is HL-2288 silica gel, the filling width is 0.5mm, and the ratio of silica gel to curing agent is 1:0.02. According to the above preparation process, the number of bases is 6 (3×2), the number of ceramic columns in each base unit is 9 (3×3), the cross-sectional size of each ceramic column is 1 mm×1 mm, and the height of the ceramic column is 13.3 mm, the ceramic column volume fraction is 42.06%, and the substrate thickness is 1.8mm. The properties of the multi-element piezoelectric composite obtained are as follows:

[0074] (1) Piezoelectric, dielectric and electromechan...

Embodiment 3

[0083] Using PZT4 piezoelectric ceramic sheet, piezoelectric constant d 33 281pC·N -1 , the electromechanical coupling coefficient K t 34.3%, relative permittivity ε r It is 1121, and the material thickness is 15.5mm. Both the polymer and the decoupling material use HL-2288 silica gel, and the ratio of silica gel to curing agent is 1:0.02. Since the polymer and the decoupling material are the same, one cutting and one filling are sufficient, and the number of bases is 45 (9×5), each base contains 9 ceramic columns (3×3), each The cross-sectional size of the ceramic column is 2mm×2mm, the height of the ceramic column is 13.5mm, the volume fraction of the ceramic column is 64.36%, and the base thickness is 2mm. The performance of the obtained multi-element piezoelectric composite material is as follows:

[0084] (1) Piezoelectric, dielectric and electromechanical coupling properties

[0085] Randomly select 5 primitives (such as Figure 7 shown), the piezoelectric, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com