Direct reduction-magnetic separation method of vanadium titanomagnetite

A vanadium-titanium-magnetite and magnetic separation technology is applied in the field of metallurgy, which can solve problems such as in-depth research, and achieve the effects of low reaction temperature, low energy consumption and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

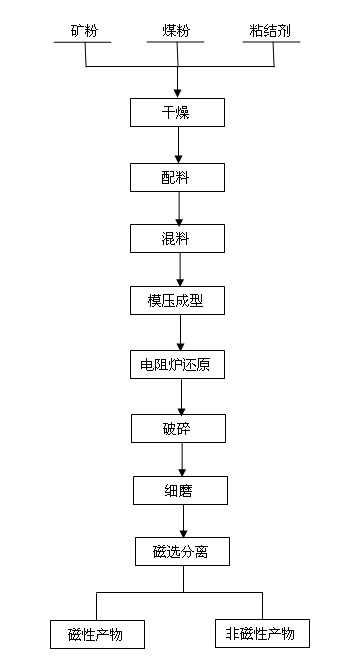

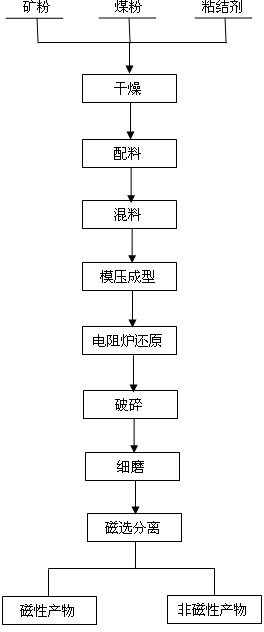

Image

Examples

Embodiment 1

[0026] Mix vanadium-titanium magnetite and anthracite coal powder according to the mass ratio of 80:20, and then grind them to -0.074mm. According to the mass percentage, add 3% polyvinyl alcohol as a binder, and place the mixture in polyurethane Put it in a ball mill tank, and then put it in a ball mill. After 24 hours of dry mixing, form a block under a molding pressure of 50Mpa to form a billet. Put the billet into a crucible, cover it with coal powder, cover the crucible lid, and put it into a resistance furnace. , reduced at 1350°C for 60min, the C / O molar ratio was 1.2, after the reduction was completed, the reduced product was crushed to -0.074mm, and then put into a magnetic separation tube for magnetic separation under a strong magnetic field of 220KA / m After 10 minutes, the reduction product was separated by magnetic separation to obtain direct reduced iron with an iron grade of 87.41%, and the iron recovery rate reached 94.99%. The metal V content in the magnetic pro...

Embodiment 2

[0028] Mix and dry vanadium-titanium magnetite and anthracite powder according to the mass ratio of 85:15, grind to -0.074mm, add 3% polyvinyl alcohol as a binder according to the mass percentage, and put the mixture in a polyurethane ball mill tank After 24 hours of dry mixing, press molding under the pressure of 30Mpa to form a billet, put the billet into the crucible and cover it with coal powder, cover the crucible lid, put it into the resistance furnace, and heat it at 1300 ℃ reduction for 180min, the C / O molar ratio is 1.4. After the reduction is completed, the reduction rate of the metal obtained after reduction reaches 94.48%. The reduced product is crushed to -0.074mm, and then put into a magnetic separation tube. Magnetic separation was carried out under a strong magnetic field for 10 minutes. After the reduction product was separated by magnetic separation, the iron recovery rate was 90.78%, the V content in the magnetic part was 0.27%, the V content in the non-magne...

Embodiment 3

[0030] Mix and dry the vanadium-titanium magnetite and bituminous coal powder according to the mass ratio of 80:20, grind to -0.074mm, add 3% polyvinyl alcohol as a binder according to the mass percentage, and place the mixture in a polyurethane ball mill After 24 hours of dry mixing, press molding under the pressure of 40Mpa to form a billet, put the billet into the crucible and cover it with coal powder, cover the crucible lid, put it into the resistance furnace, and Reduction at 1250°C for 300 minutes, the C / O molar ratio is 1.2. After the reduction is completed, the reduction rate of the metal obtained after reduction reaches 85.68%. The reduced product is crushed to -0.074mm, and then put into a magnetic separation tube. Magnetic separation was carried out under a strong magnetic field for 10 minutes. After the reduction product was separated by magnetic separation, direct reduced iron with an iron grade of 86.85% was obtained, and the recovery rate was 92.03%. The metal V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com