Production method of cefpirome sulfate/ sodium chloride injection non-PVC (polyvinyl chloride) instant matched injection

A technology of sodium chloride injection and cefpirome sulfate, which is applied in the direction of chemical instruments and methods, layered products, liquid materials, etc., can solve the problem of not considering the compatibility of drugs and bags, not considering the impact, and isolation safety no problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

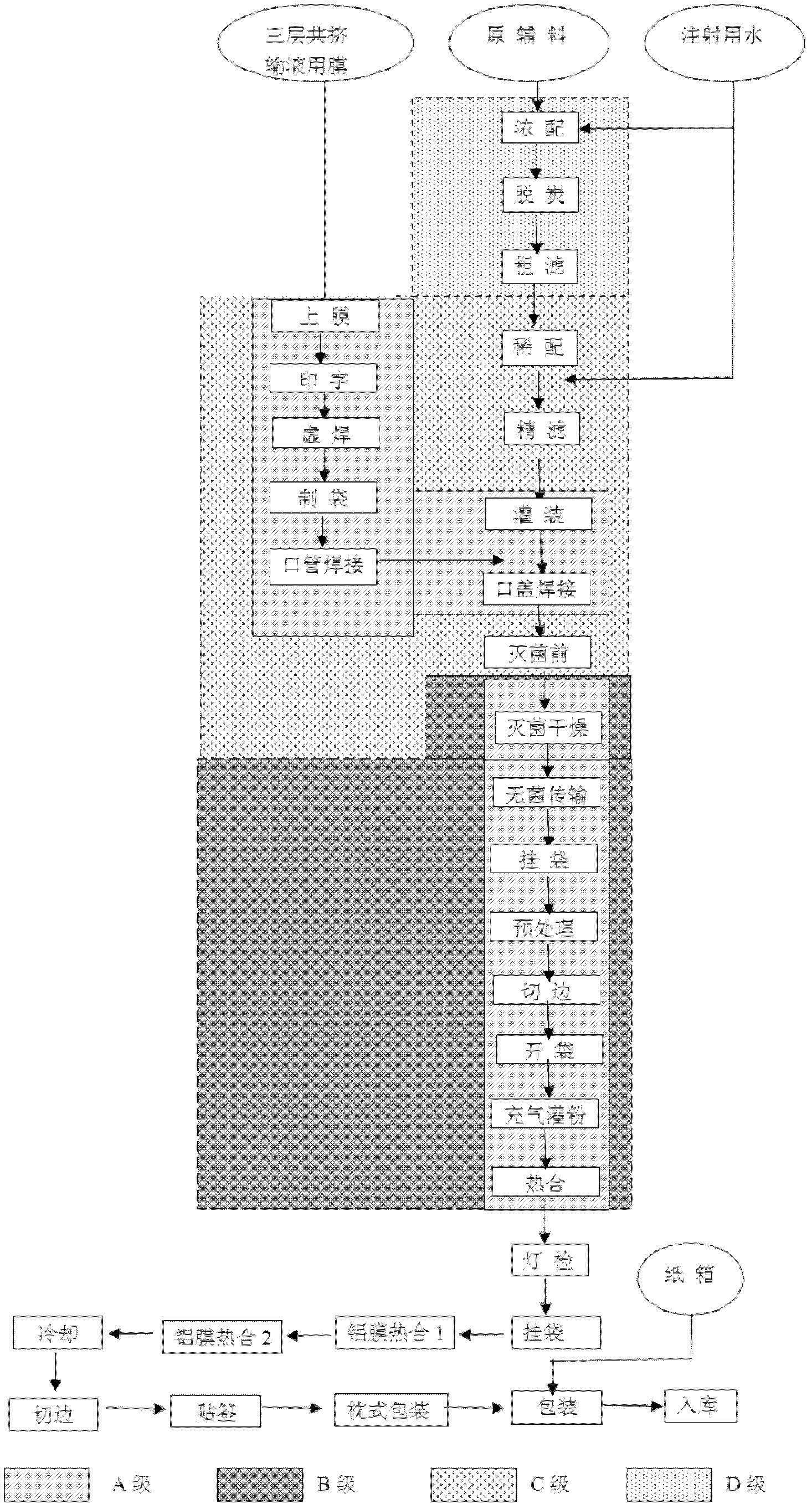

[0049] Embodiment: The process steps include: preparation of liquid medicine, bag making and filling, sterilization and drying, powder injection sub-packaging, light inspection, aluminum foil welding, labeling, and pillow packaging.

[0050] 1) Preparation of medicinal solution: According to the prescription ratio and batch weighing of each raw and auxiliary material, 0.9% sodium chloride injection was prepared according to the method shown in the summary of the invention.

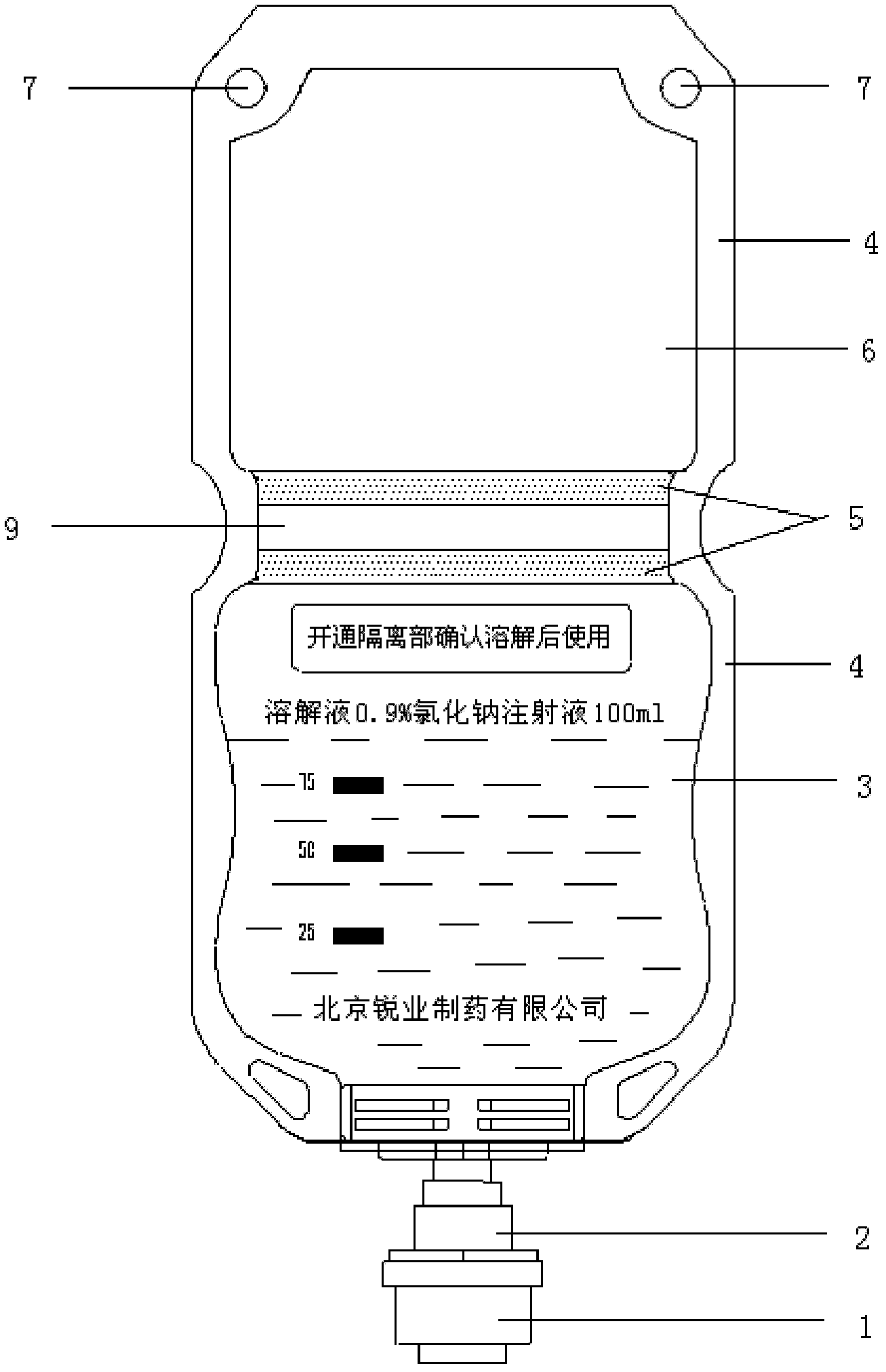

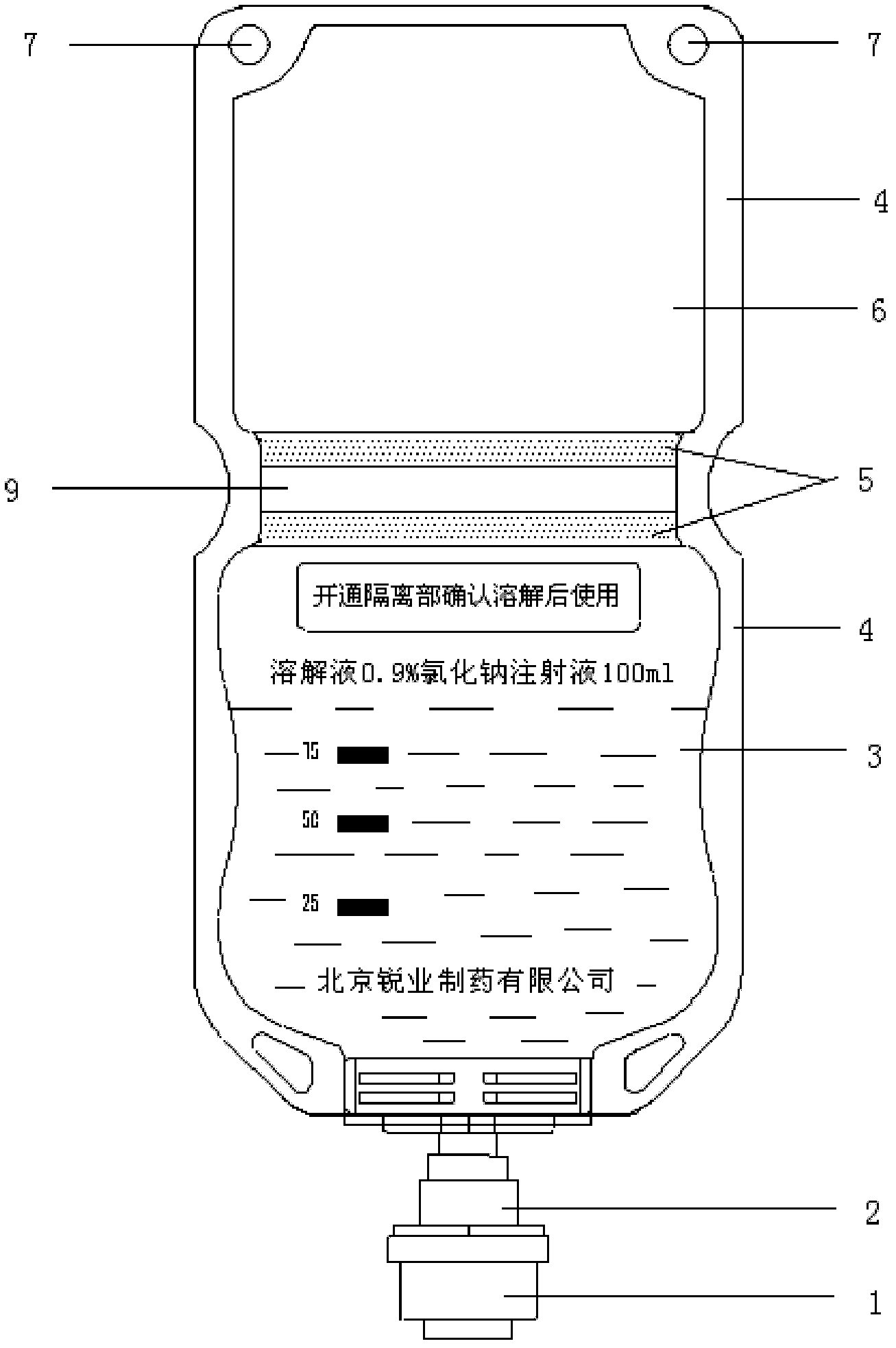

[0051] 2) Bag making and filling: film coating→film pulling→liquid chamber printing→virtual welding 5→peripheral welding→mouth tube 2 delivery→mouth tube 2 preheating→mouth tube 2 welding→mouth tube 2 shaping→tearing waste edge→ Bag transfer→vacuum leak detection→bag overturning and positioning→bag receiving→liquid chamber 3 filling with 0.9% sodium chloride injection solution→melt sealing of polypropylene combination cap 1 and mouth tube 2→bottom bag by manipulator to produce figure 2 The bag shown has a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat seal strength | aaaaa | aaaaa |

| Pressure resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com