Gypsum marble and its preparation method

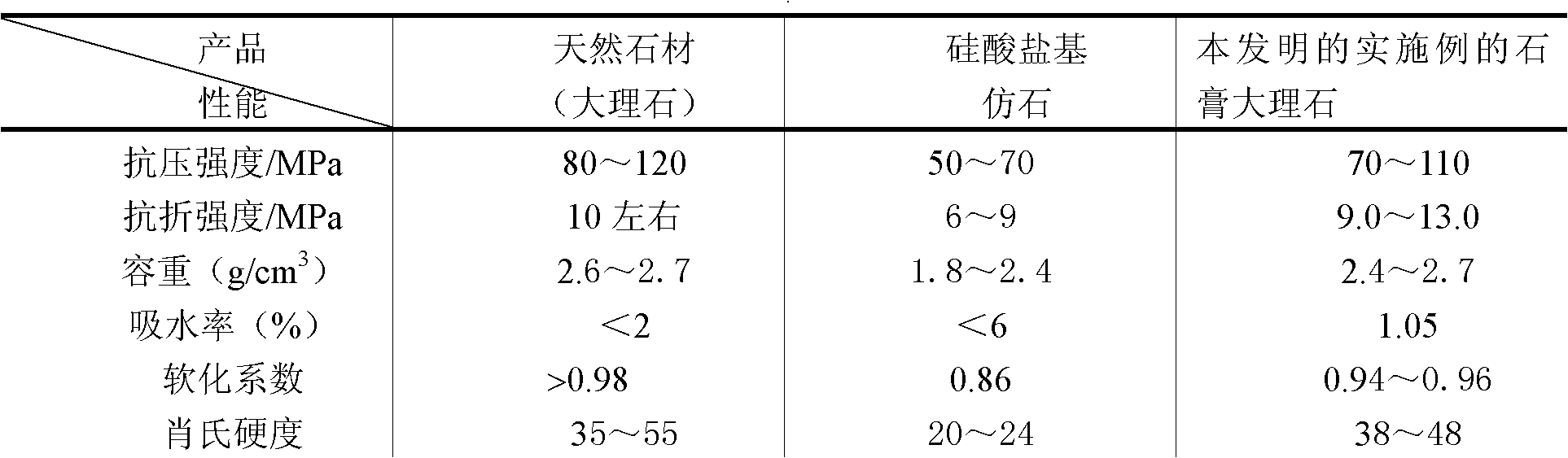

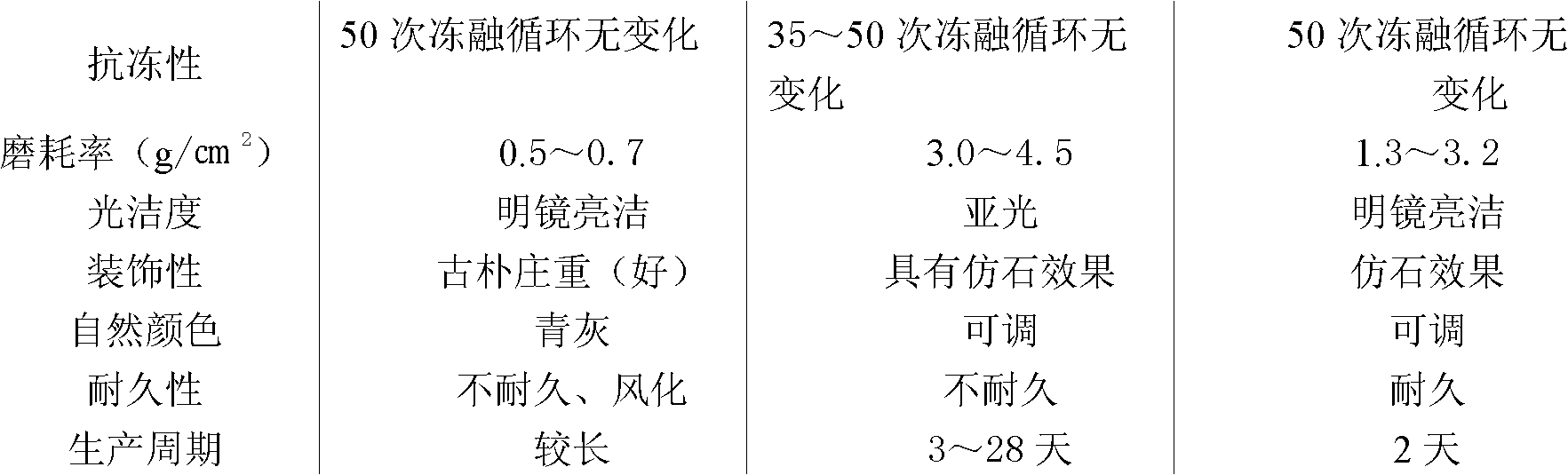

A marble and gypsum technology, applied in the field of gypsum marble and preparation, can solve the problems of lack of coherence and integrity of product application, technical bottleneck, single product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

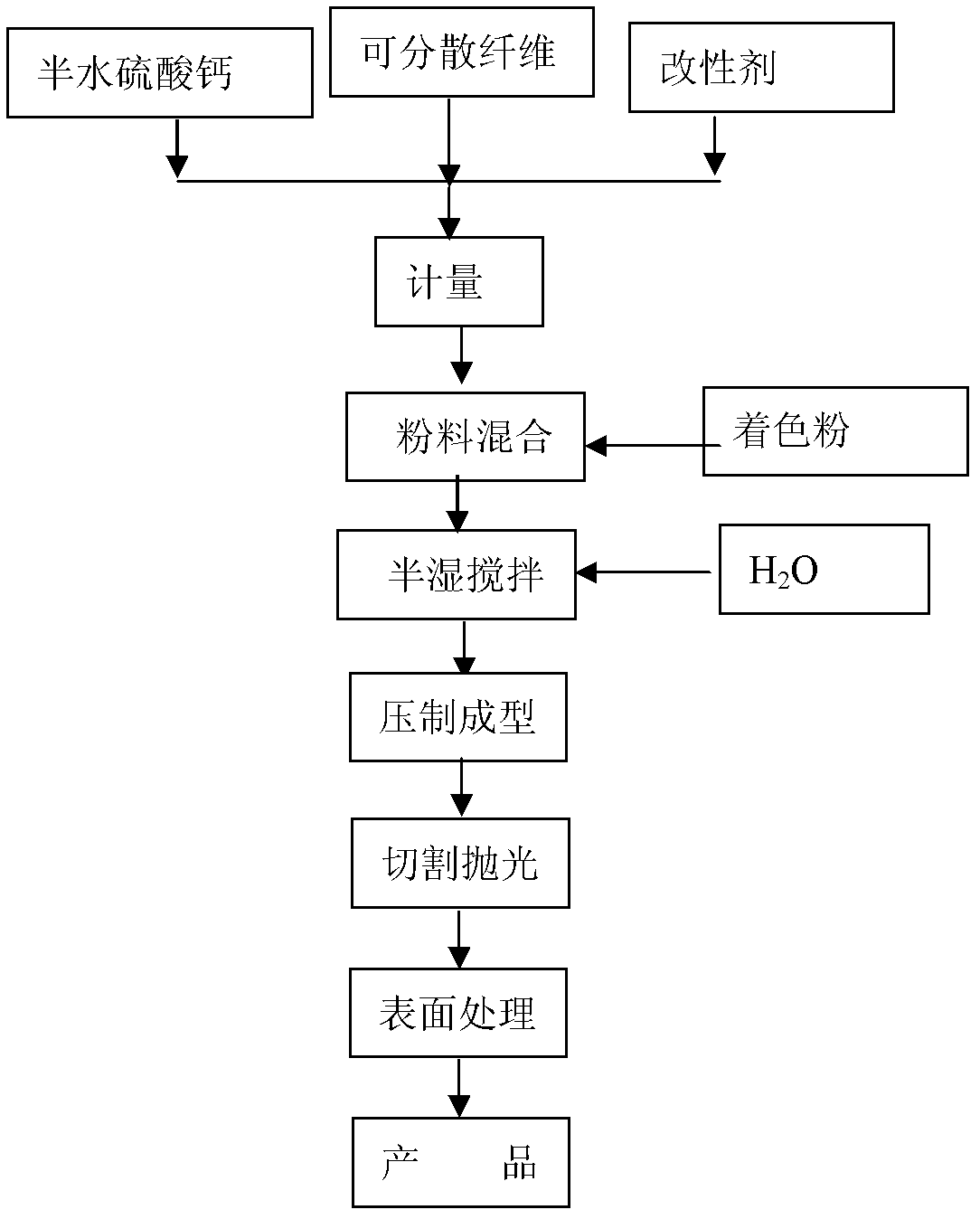

Method used

Image

Examples

Embodiment 1

[0029] 1) Formula composition (substance measurement units are parts by mass):

[0030] (1) Calcium sulfate hemihydrate: 100 parts of natural alpha type;

[0031] (2) Dispersible fiber: 3.0 parts of acrylic fiber, fiber length 8mm;

[0032] (3) Modifier: 0.8 part of dispersible powder, 0.0024 part of potassium aluminum sulfate, 0.0012 part of calcium chloride, 0.8 part of waterproof silicon powder;

[0033] (4) Coloring powder: fluorescent white 2.0 parts

[0034] (5) Clear water: 18.63 parts

[0035] 2) Process:

[0036] 1) Continuous powder metering: natural α-type calcium sulfate hemihydrate, propylene fiber, modifier, and coloring powder are respectively continuously metered by a spiral reamer and a fiber chopping machine;

[0037] 2) Continuous mixing of dry powder: each powder is continuously measured and then enters the spiral reamer mixing device to realize continuous stirring of standard powder and continuous measurement of standard powder;

[0038] 3) Continuous...

Embodiment 2

[0044] 1) Formula composition (substance measurement units are parts by mass):

[0045] (1) Calcium sulfate hemihydrate: 20 parts of natural α type, 80 parts of natural β type;

[0046] (2) Dispersible fibers: 1.0 parts of acrylic fiber, 4.0 parts of glass fiber, with a length of 6.5 mm to 8 mm;

[0047] (3) Modifier: 0.6 part of dispersible powder, 0.0018 part of aluminum potassium sulfate, 0.0012 part of calcium chloride, 0.6 part of waterproof silicon powder;

[0048] (4) Toner: 6.0 parts of bright red water-soluble toner

[0049] (5) Clear water: 18.63 parts

[0050] 2) Process:

[0051] 1) Continuous metering of powder: natural α-type calcium sulfate hemihydrate, 80 parts of natural β-type, acrylic fiber, glass fiber, modifier, and coloring powder are respectively continuously metered by a spiral reamer and a fiber chopping machine;

[0052] 2) Continuous mixing of dry powder: each powder is continuously measured and then enters the spiral reamer mixing device to realiz...

Embodiment 3

[0059] 1) Formula composition (substance measurement units are parts by mass):

[0060] (1) Calcium sulfate hemihydrate: 50 parts of desulfurization-α type, 50 parts of desulfurization-β type;

[0061] (2) Dispersible fibers: 2.0 parts of acrylic fiber, 2.0 parts of glass fiber, with a length of 6.5 mm to 8 mm;

[0062] (3) Modifier: 0.3 part of dispersible powder, 0.0009 part of potassium aluminum sulfate, 0.0006 part of calcium chloride, 0.3 part of waterproof silicon powder;

[0063] (4) Coloring powder: 0.05 parts of blue glass powder

[0064] (5) Clear water: 18.63 parts

[0065] 2) Process:

[0066] 1) Continuous metering of powder: desulfurization α-type calcium sulfate hemihydrate, desulfurization β-type 80 parts, acrylic fiber, glass fiber, modifier, and coloring powder are respectively continuously metered by a spiral reamer and a fiber chopping machine;

[0067] 2) Continuous mixing of dry powder: each powder is continuously measured and then enters the spiral r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com