Method for preparing natural haematochrome zinc porphyrin

A technology of natural red pigment porphyrin zinc, applied in the field of preparation of natural red pigment porphyrin zinc, to achieve the effects of avoiding health hazards, good color rendering effect, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Zn 2+ Preparation of chelatase

[0029] (a) Clean beef liver, pig liver, and animal heart, weigh 100 g of evenly chopped beef liver, pig liver, and animal heart, put them into a pre-cooled tissue grinder, add cooling distilled water of equal quality to grind it.

[0030] (b) Centrifuge the minced meat at 15,000 g for 8-15 min at 4°C, and remove the supernatant.

[0031] (c) The cell tissue in the lower layer was dissolved and mixed with distilled water, centrifuged under the same conditions, and the operation was repeated 2-3 times.

[0032] (d) The obtained cell tissue pellet was stored at 4°C for future use.

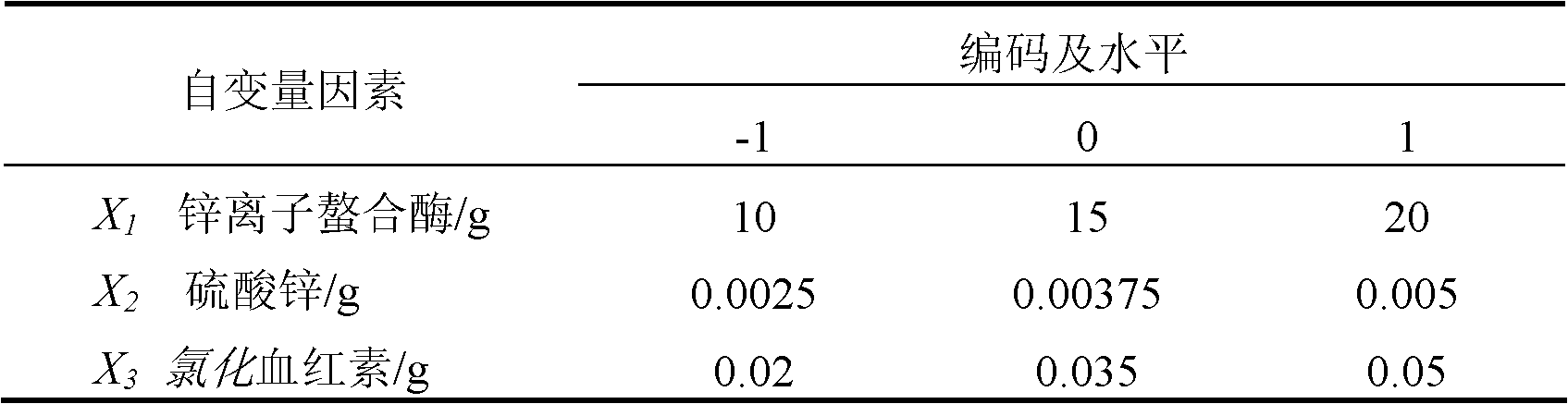

[0033] 2. BBD response surface experimental design optimization

[0034] 2.1 Experimental method

[0035] (a) Weigh the prepared Zn respectively 2+ Chelatease, hemin and zinc sulfate powder, add distilled water to dissolve to a total volume of 100mL, mix well;

[0036] (b) The mixed solution is placed in a water bath, and reacted at 60° C. for 6 hours; ...

Embodiment 2

[0060] (1)Zn 2+ Preparation of chelatase

[0061] With embodiment 1.

[0062] (2) Preparation of porphyrin zinc:

[0063] (a) Weigh the prepared Zn respectively 2+ Chelatease, protoporphyrin disodium and zinc chloride powder, add distilled water to a total volume of 100mL to dissolve and mix, so that Zn 2+ The concentration of chelatase is 0.1g / mL, the concentration of disodium protoporphyrin is 1g / L, and the concentration of zinc chloride is 0.1g / L;

[0064] (b) The mixed solution is placed in a water bath, and reacted at 55° C. for 7 hours;

[0065] (c) 75% acetone of 1 times the volume of the above mixed solution was added to extract zinc porphyrin, and the concentration of zinc porphyrin was detected by the fluorescence spectrophotometry described in Example 1 to be 985.34 mg / L.

[0066] (3) Separation and purification of porphyrin zinc:

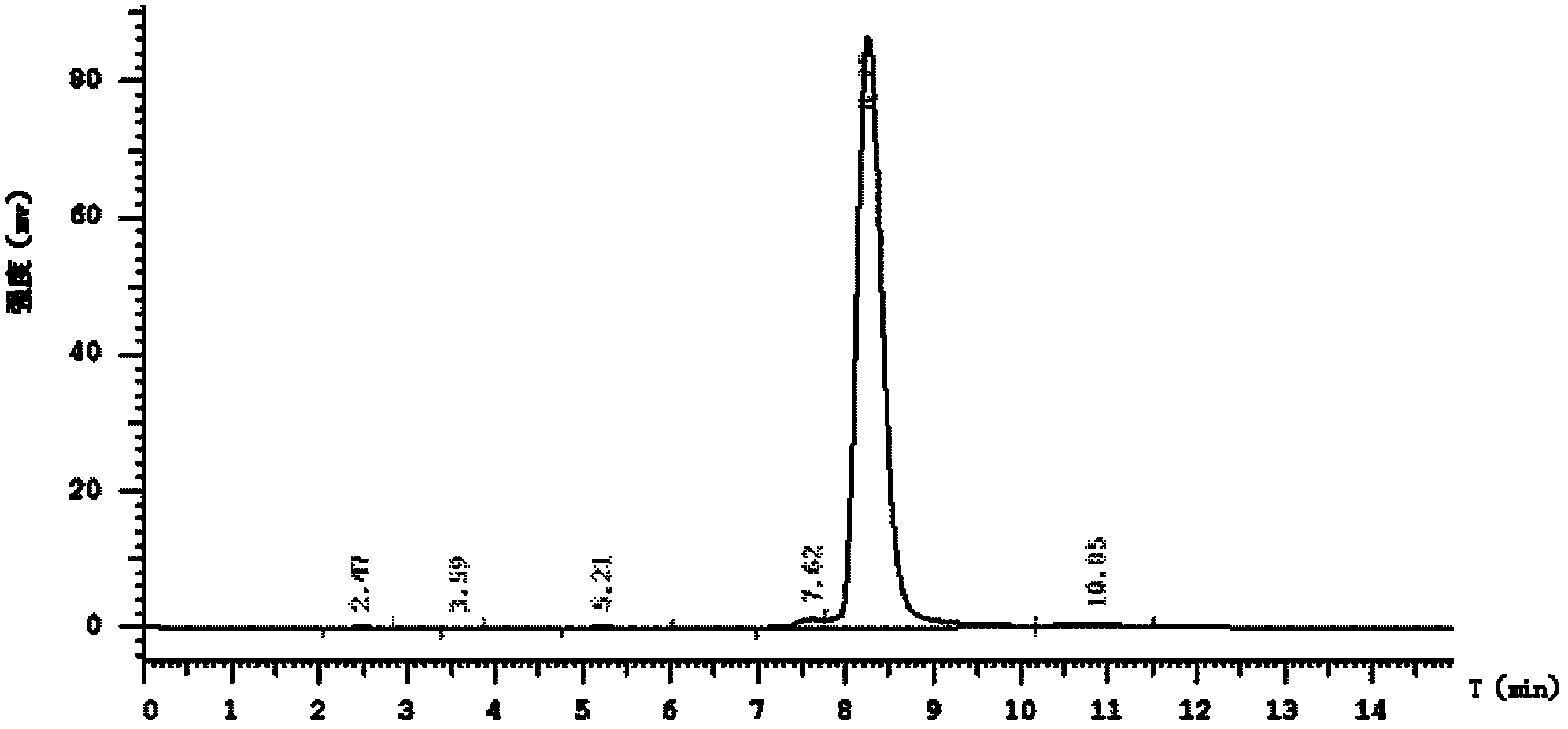

[0067] The prepared porphyrin zinc is separated and purified by high performance liquid chromatography, which specifically includ...

Embodiment 3

[0075] (1)Zn 2+ Preparation of chelatase

[0076] With embodiment 1.

[0077] (2) Preparation of porphyrin zinc:

[0078] (a) Weigh the prepared Zn respectively 2+ Chelatease, hemin and zinc citrate powder, add distilled water to a total volume of 100mL to dissolve and mix, so that Zn 2+ The concentration of chelatase is 0.2g / mL, the concentration of hemin is 3g / L, and the concentration of zinc citrate is 0.8g / L;

[0079] (b) The mixed solution is placed in a water bath, and reacted at 60°C for 5.5h;

[0080] (c) Adding 75% acetone twice the volume of the above mixed solution to extract porphyrin zinc, the concentration of porphyrin zinc detected by the fluorescence spectrophotometry described in Example 1 was 673.21mg / L.

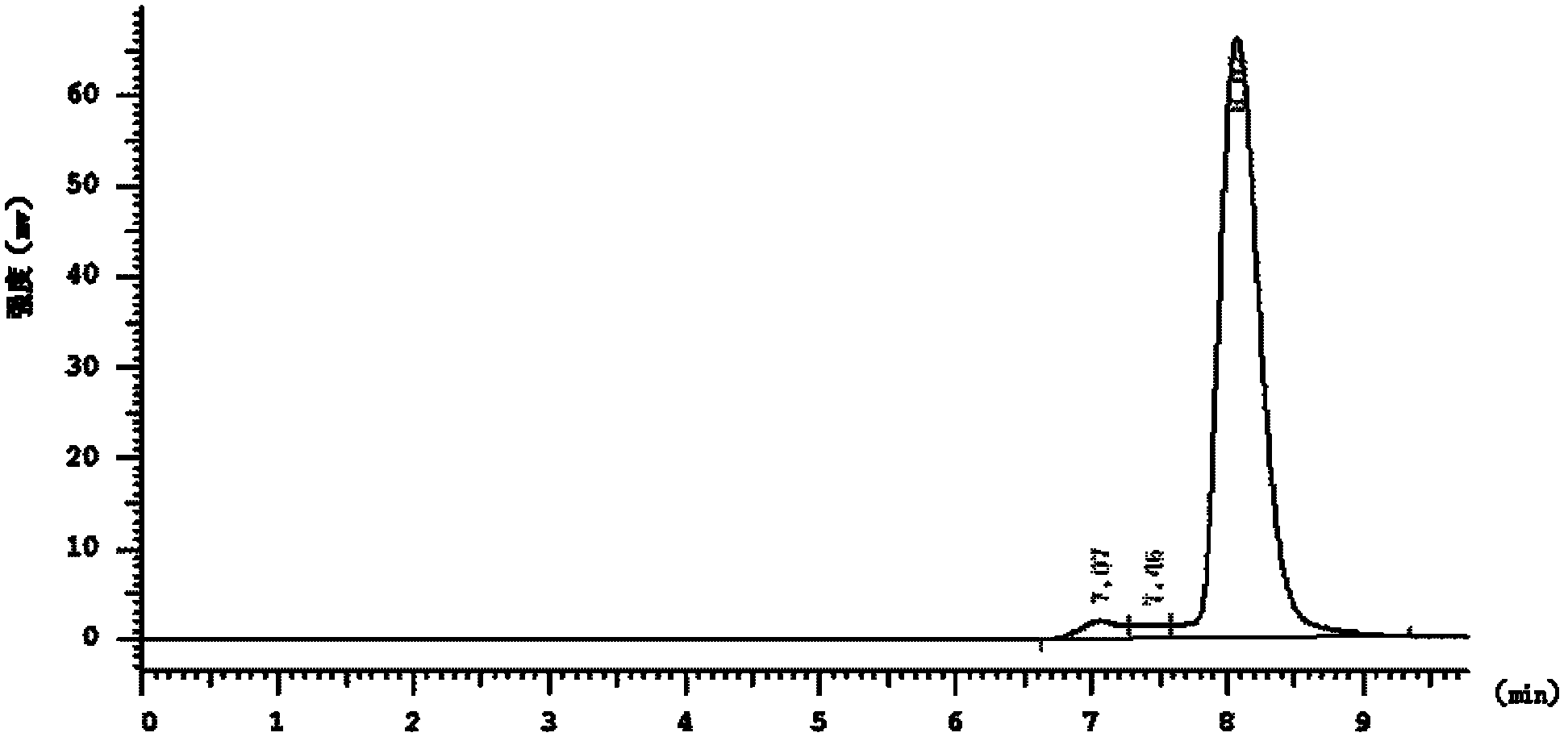

[0081] (3) Separation and purification of porphyrin zinc:

[0082] The prepared porphyrin zinc is separated and purified by high performance liquid chromatography, which specifically includes the following steps:

[0083] (a) Set the column temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com