Optical fiber beam combiner and manufacturing method thereof

An optical fiber combiner and manufacturing method technology, which is applied in the field of pump laser beam combiners, can solve the problems that the optical fiber combiner cannot withstand, the power loss at the fusion point is large, and the structure of the fiber waveguide is damaged, so as to overcome the laser resistance The effect of low power, increased strength, and improved pump coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

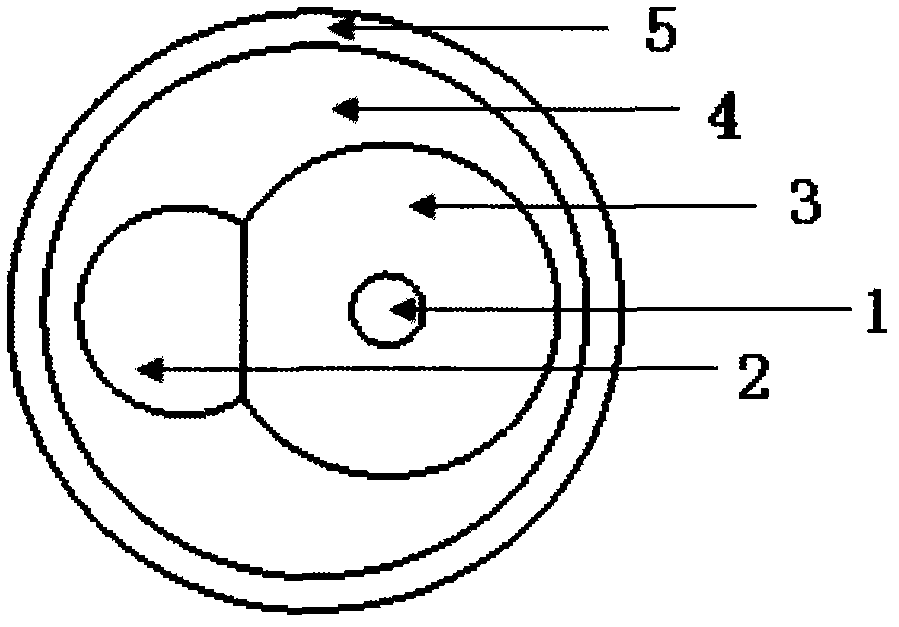

[0033] Example 1: Active fiber glass rod is D-shaped

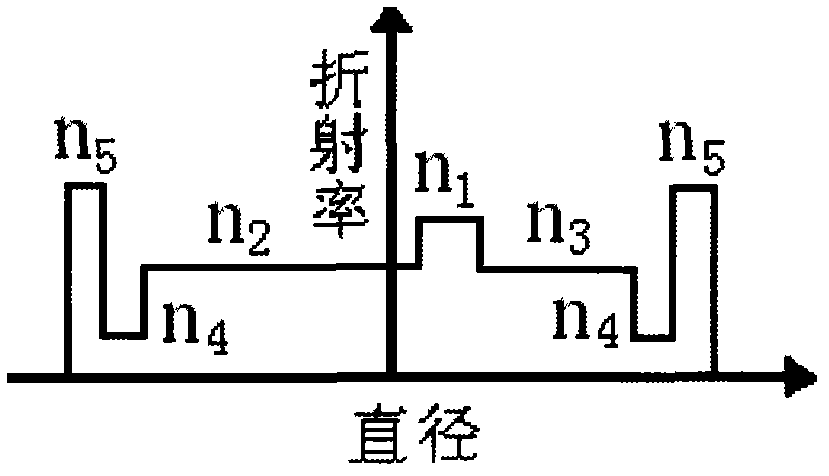

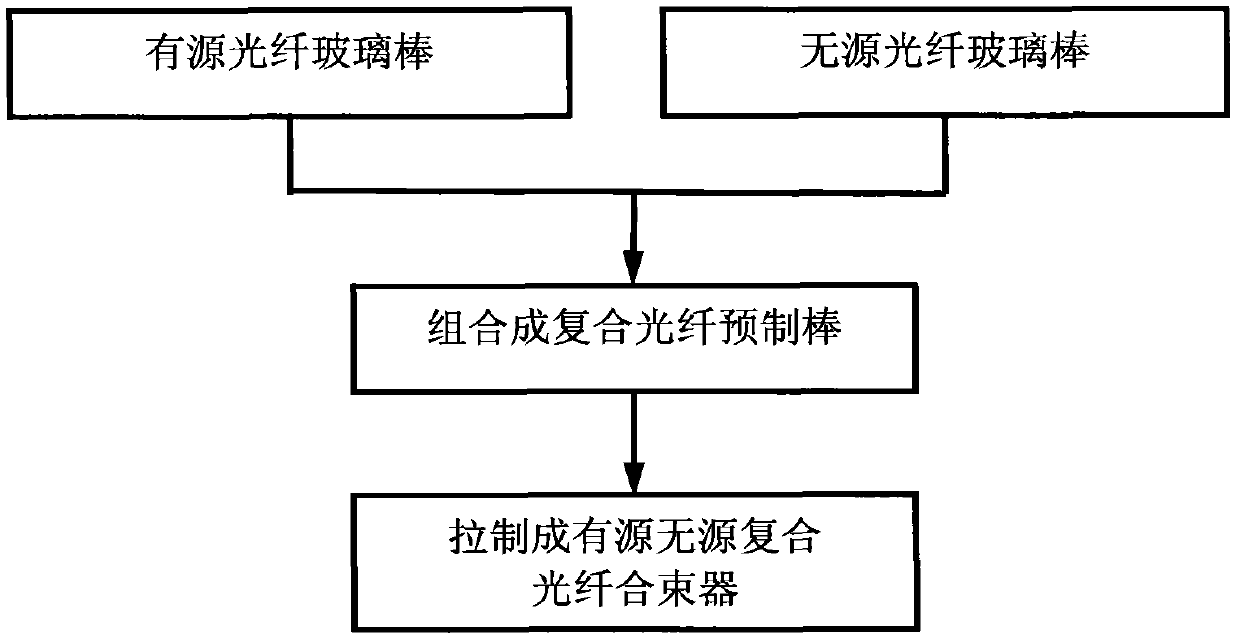

[0034] Take a pre-prepared ytterbium-doped silica glass rod (active fiber), the diameter of the ytterbium-doped core layer is 0.9mm, and the refractive index n of the core 1 of the active fiber 1 =1.4592, the diameter of the silica cladding (the inner cladding 3 of the active fiber) is 18mm, and the refractive index is n 3 =1.4571, grind it into a D shape, and the grinding thickness of the glass rod is 2.25mm; 2 =1.4571, its diameter is 12mm, and the grinding thickness of the glass rod is 2.65mm; then, the D-shaped straight edge of the ytterbium-doped quartz glass rod and the D-shaped straight edge of the coreless pure quartz glass rod are spliced along the axial direction to form Composite fiber preform.

[0035] The composite optical fiber preform is placed on the drawing tower equipment, and the high temperature furnace is heated to 1900 ℃. 4 The UV-curable acrylic paint with = 1.37 is coated on the glass fiber, an...

Embodiment 2

[0037] Example 2: Active fiber glass rod is hexagonal

[0038] Take a pre-prepared ytterbium-doped silica glass rod (active fiber), the diameter of the ytterbium-doped core layer is 1.0mm, and the refractive index n of the core 1 of the active fiber 1 =1.4586, the diameter of the silica cladding (inner cladding 3 of the active fiber) is 15.0 mm, and the refractive index is n 3 =1.4571, grind it into a hexagonal shape, and the grinding thickness of each side of the glass rod is 1.0mm; 2 =1.4571, its diameter is 15mm, and the grinding thickness of the glass rod is 3.70mm; then, a straight edge of the ytterbium-doped quartz glass rod and a straight edge of the coreless pure quartz glass rod are spliced along the axial direction to form a composite Optical fiber preform.

[0039] The composite optical fiber preform is placed on the drawing tower equipment, and the high temperature furnace is heated to 2100 ℃. 4 The UV-curable acrylic paint of = 1.37 is coated on the glass fib...

Embodiment 3

[0041] Example 3: The active optical fiber glass rod is octagonal

[0042] Take a pre-prepared ytterbium-doped silica glass rod (active fiber), the diameter of the ytterbium-doped core layer is 1.5mm, and the refractive index n of the core 1 of the active fiber 1 =1.46036, the diameter of the silica cladding (inner cladding 3 of the active fiber) is 30mm, and the refractive index is n 3 =1.4571, grind it into an octagonal shape, and the grinding thickness of each side of the glass rod is 1.15mm; 2 = 1.4571, its diameter is 20mm, and the grinding thickness of the glass rod is 2.0mm; then, a straight edge of the ytterbium-doped silica glass rod and a straight edge of the coreless pure silica glass rod are spliced along the axial direction to form a composite optical fiber preform.

[0043] The composite optical fiber preform is placed on the drawing tower equipment, and the high temperature furnace is heated to 2200 ℃. 4 The UV-curable acrylic paint of = 1.37 is coated on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com