MRESI (multichannel rotating electrospray ionization) mass spectrometric analysis ion source

An electrospray ionization and mass spectrometry analysis technology, applied in the field of chemical analysis, can solve the problems of inability to realize simultaneous analysis of complex samples, low sample utilization rate, and inability to analyze samples with multiple spray solvents at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

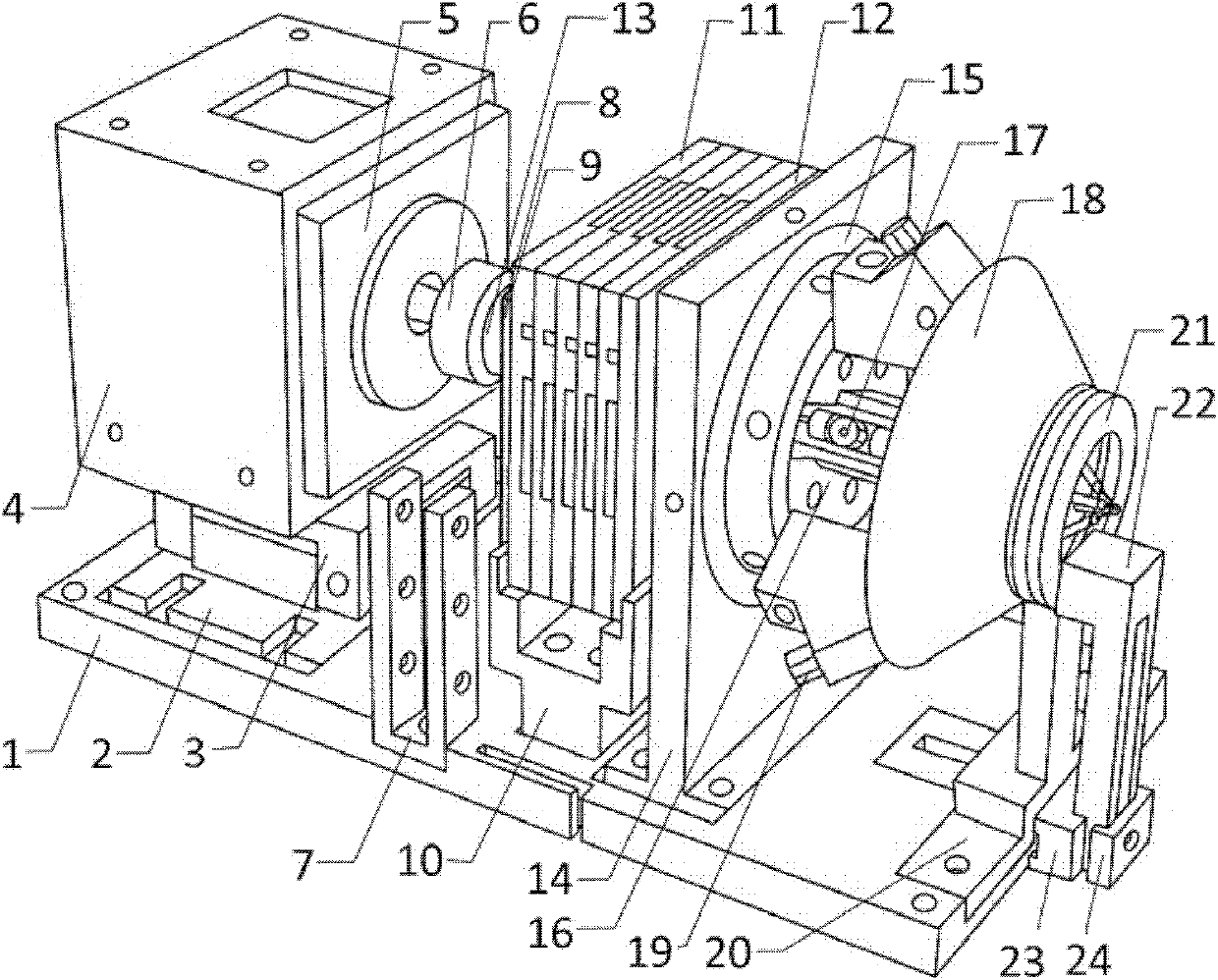

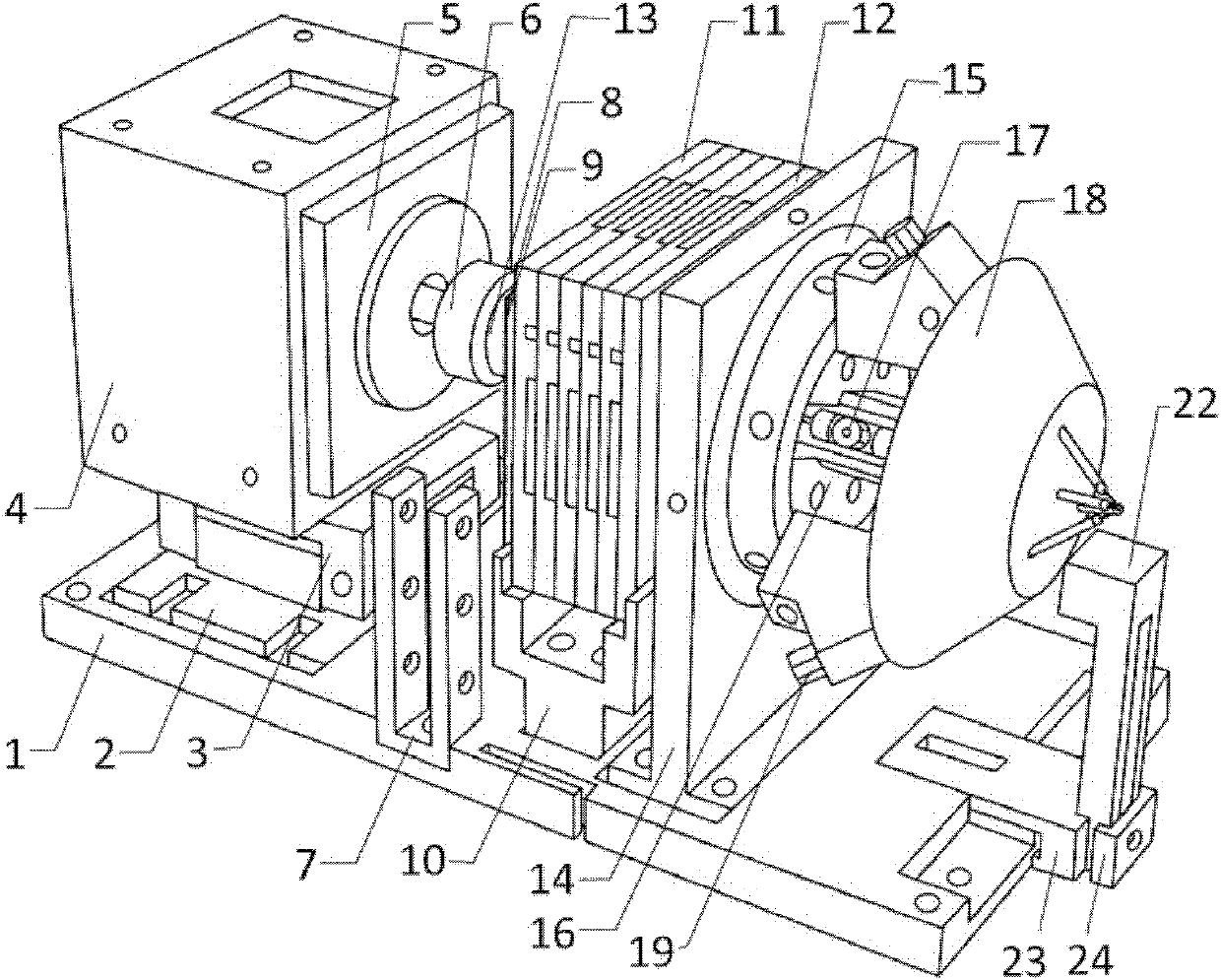

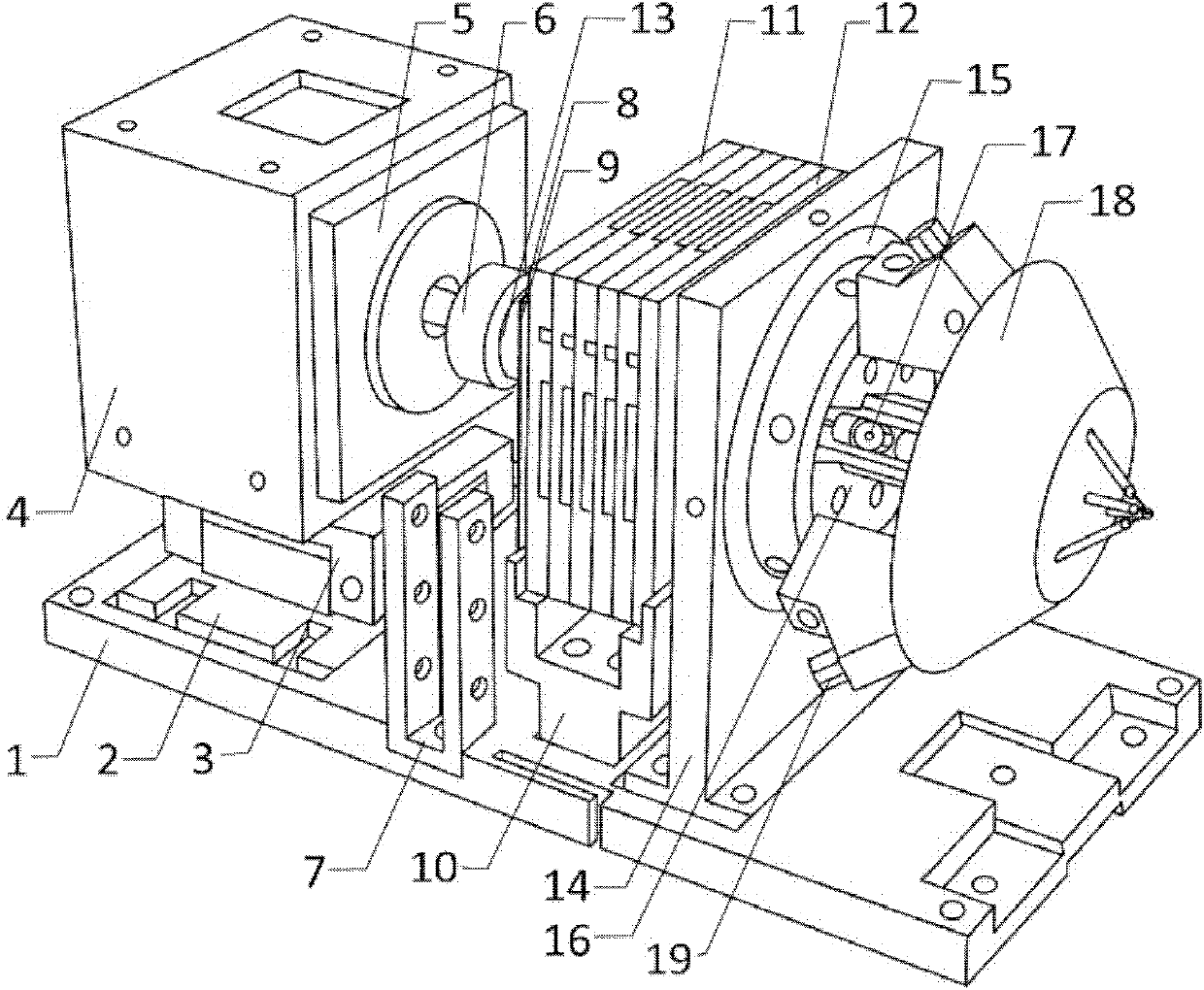

[0020] Refer to the following Figure 1 to Figure 10 Examples of the present invention will be described.

[0021] In order to make the above objects, features and advantages more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] The invention provides a multi-channel rotary electrospray ionization mass spectrometry ion source, which can be equipped with a plurality of spray needles equipped with independent pipelines and independent circuits, and these spray needles rotate with the stepping motor at the same time, so that the The spray (electrospray or electroneutral spray) is evenly mixed and enters the mass spectrometry inlet at the same time.

[0023] The ion source structure of the multi-channel rotary electrospray ionization mass spectrometry analysis provided by the invention is as follows: Figure 1-Figure 3 , including a base 1, a motor adjustment part, inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com