Adhesive layer, adhesive member, method for producing same, and image display device

A technology of adhesive layer and manufacturing method, applied in the direction of adhesive type, ester copolymer adhesive, film/sheet adhesive, etc., can solve the problem that water-dispersed adhesive is difficult to apply to optical applications, etc. problem, to achieve the effect of preventing air bubbles from mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

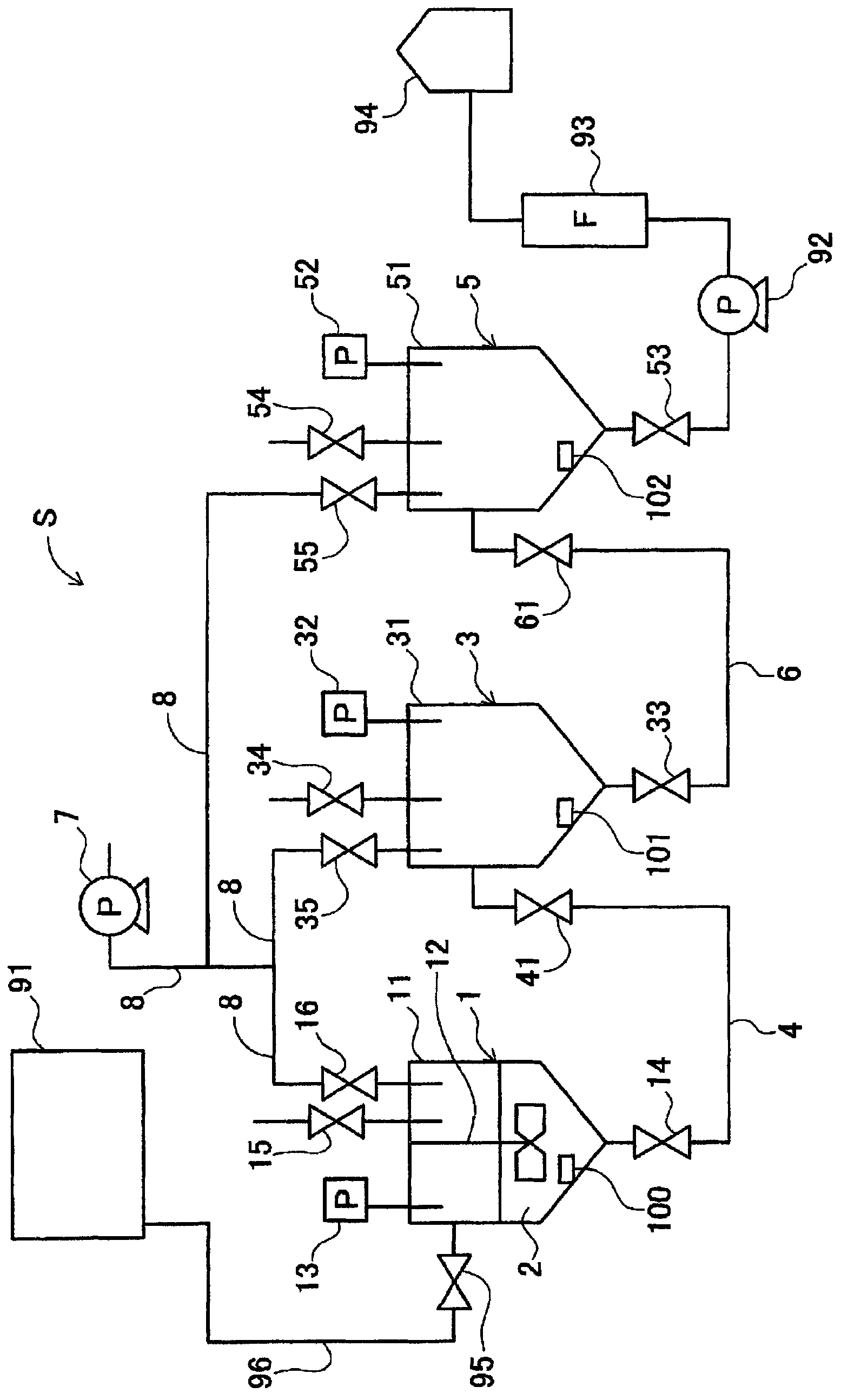

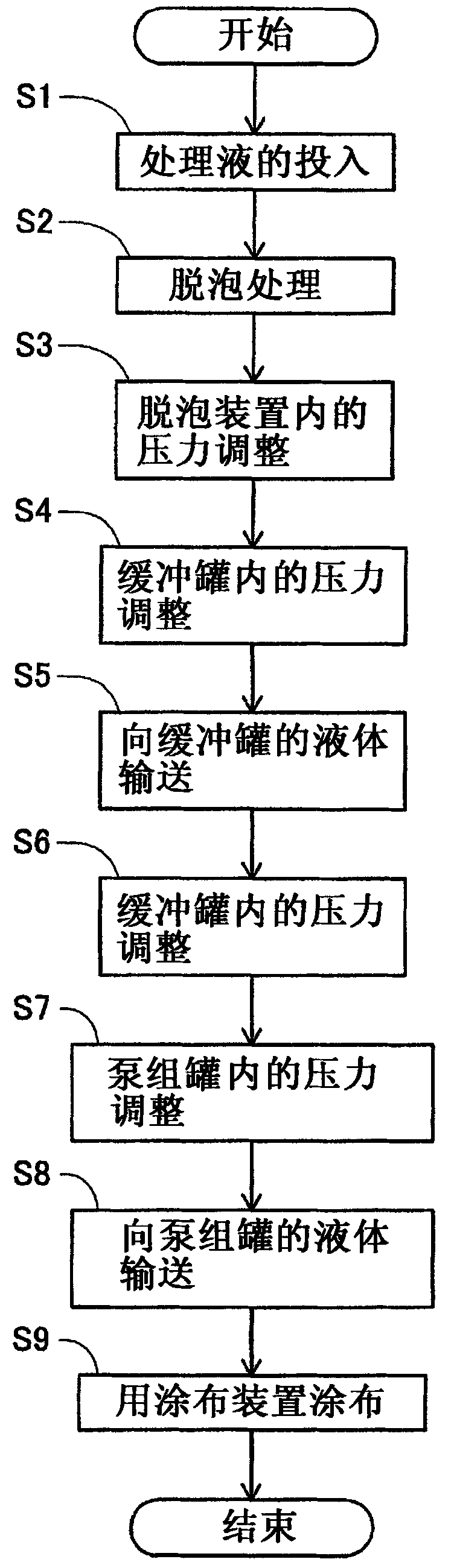

Method used

Image

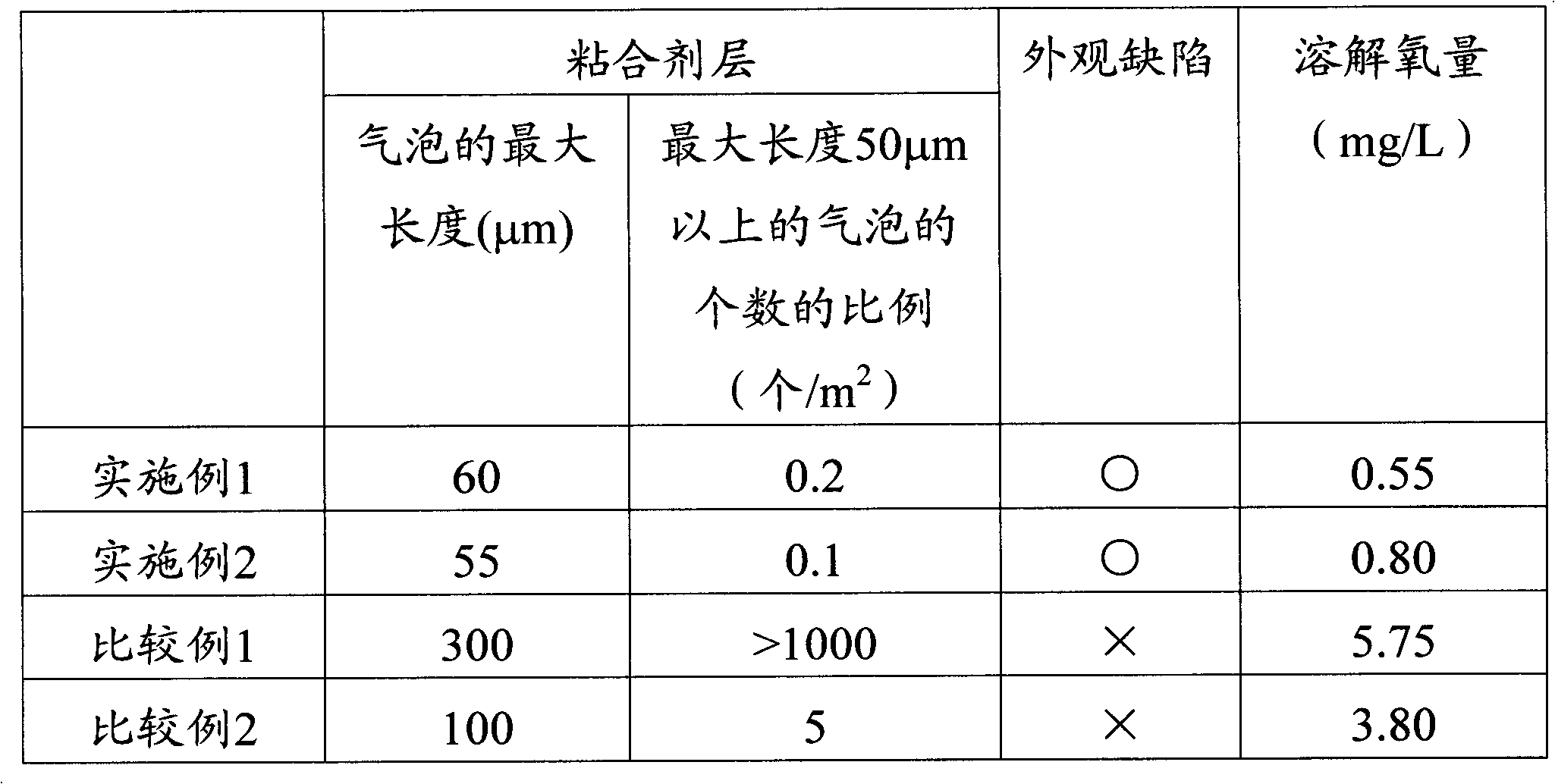

Examples

Embodiment 1

[0155] (preparation of pre-emulsion)

[0156] Add 92 parts of butyl acrylate, 6 parts of methacrylic acid, 2 parts of mono[poly(oxypropylene) methacrylate] phosphate (the average degree of polymerization of propylene oxide is about 5.0), 0.03 parts of 3- Methacryloxypropyl-trimethoxysilane (KBM-503, manufactured by Shin-Etsu Chemical Co., Ltd.) was mixed to prepare a mixture of reaction components. Next, 46.6 g of reactive emulsifier Aqualon HS-10 (Daiichi Kogyo Pharmaceutical Co., Ltd.) and 346 g of ion-exchanged water were added to 388 g of the prepared reaction component mixture. Manufacturing), stirred at 5000 (l / min) for 5 minutes, forced emulsification, and prepared monomer pre-emulsion.

[0157] (Preparation of emulsion solution of water-dispersed copolymer)

[0158] In the reaction vessel with cooling pipe, nitrogen inlet pipe, thermometer and stirrer, add 156g, 219g ion-exchanged water in the monomer pre-emulsion prepared above, then, replace the reaction vessel wit...

Embodiment 2

[0176] (Preparation of Water Dispersible Adhesive)

[0177]30 parts of water and 0.3 parts of ammonium persulfate were added to a reaction vessel provided with a cooling pipe, a nitrogen introduction pipe, a thermometer and a stirring device, and nitrogen replacement was carried out for 1 hour while stirring. 95 parts of 2-ethylhexyl acrylate, 5 parts of acrylic acid, and 1.0 part (in terms of solid content) of polyoxyethylene lauryl as an emulsifier were added dropwise to the above container over 3 hours at 80°C with 70 parts of water What was obtained by emulsifying ammonium ether sulfate (trade name "HITENOL LA-16" of Daiichi Kogyo Pharmaceutical Co., Ltd.) was further aged at 80° C. for 2 hours. Thereafter, it was cooled to room temperature, and the pH was adjusted to 8 with 10% by weight of ammonia water to obtain a copolymer emulsion. In this copolymer emulsion, 0.1 part (in terms of solid content) of Nippon Shokubai Co., Ltd. as a water-soluble crosslinking agent conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com