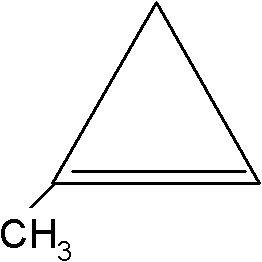

1-methylcyclopropene preparation and preparation method thereof

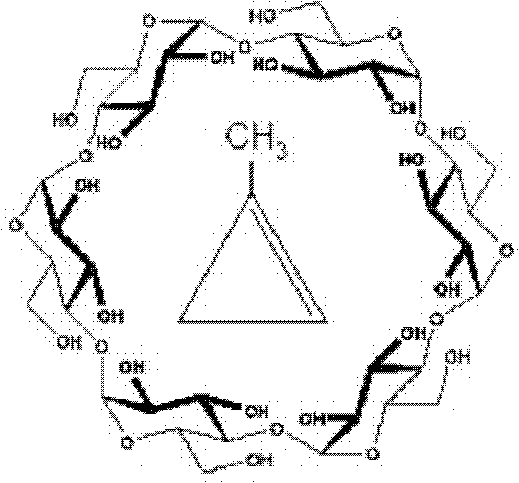

A methylcyclopropene and preparation technology, which is applied in botany equipment and methods, biocides, animal repellants, etc., can solve the problems of restricting large-scale use, complicated production process, high price, etc., and achieve high efficiency of storage and release , convenient transportation and storage, and the effect of extending the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

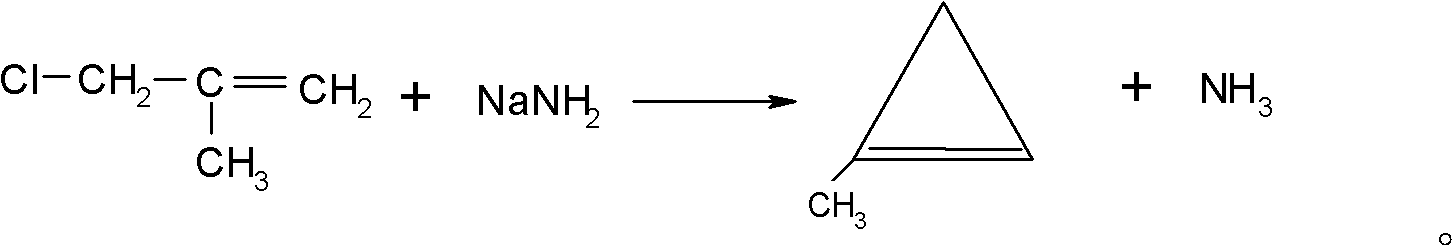

Method used

Image

Examples

Embodiment 1

[0049] Activated carbon is used as the preparation of the 1-MCP preparation of adsorbent, comprises the following steps:

[0050] 1) Activation of activated carbon:

[0051] According to the following ratio: mix 250mL of 0.3mol / L hydrochloric acid and 250mL of 0.1mol / L nitric acid, then add 100g of 60-80 mesh coconut shell activated carbon, stir at room temperature for 30 minutes and then filter, wash the filter cake with deionized water until neutral , After drying at 250°C, activate at 600°C for more than 1 hour. After the above steps, the metal ions and organic matter in the activated carbon can be removed.

[0052] 2) Adsorption of 1-MCP by activated carbon

[0053] According to the following ratio: 10mL liquid paraffin, 10g powdered sodium amide and 0.4g hexamethyldisilazane were added to the reactor, and 20g 3-chloro-2- Methyl propylene was added dropwise into the flask, and the generated gas passed through two washing bottles and an absorbing bottle successively unde...

Embodiment 2

[0064] Activated carbon is used as the preparation of the 1-MCP preparation of adsorbent, comprises the following steps:

[0065] 1) Activation of activated carbon:

[0066] According to the following ratio: mix 250mL of 0.3mol / L hydrochloric acid and 250mL of 0.15mol / L nitric acid, then add 100g of 60-80 mesh coconut shell activated carbon, stir at room temperature for 30 minutes and filter, and wash the filter cake with deionized water until neutral , After drying at 200°C, activate at 800°C for more than 1 hour. After the above steps, the metal ions and organic matter in the activated carbon can be removed.

[0067] 2) Adsorption of 1-MCP by activated carbon

[0068] According to the following ratio: 10mL liquid paraffin, 10g powdered sodium amide and 0.4g hexamethyldisilazane were added to the reactor, and 20g 3-chloro-2- Methyl propylene was added dropwise into the flask, and the generated gas passed through two washing bottles and an absorbing bottle successively unde...

Embodiment 3

[0072] Preparation and Application of Zeolite Adsorbed 1-MCP Preparation

[0073] Wash the 5A zeolite with a particle size of 2-4mm in water, dry it at 200°C and activate it at 750°C for 2 hours; then suspend the zeolite in water according to the proportion of adding 500g of zeolite to 1500mL of water;

[0074] The preparation of 1-MCP, the carrying and scrubbing of nitrogen are the same as in Example 1. The 1-MCP carried by nitrogen is passed into the water suspended with zeolite for adsorption. Gas 1.5g; add 0.002% p-hydroxyanisole by zeolite mass, mix thoroughly and store in airtight.

[0075] The release operation is as follows: a total of 1.3 g of gas is released after heating the zeolite preparation to 80° C., and the purity is 98.6% after detection by GC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com