Benzene chloride tail gas recovering and purifying method

A tail gas recovery and benzene chlorination technology, which is applied to chemical instruments and methods, separation methods, and dispersed particle separation, can solve problems such as high product benzene consumption, material loss, and environmental pollution, and achieve large processing capacity and overall High efficiency and environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

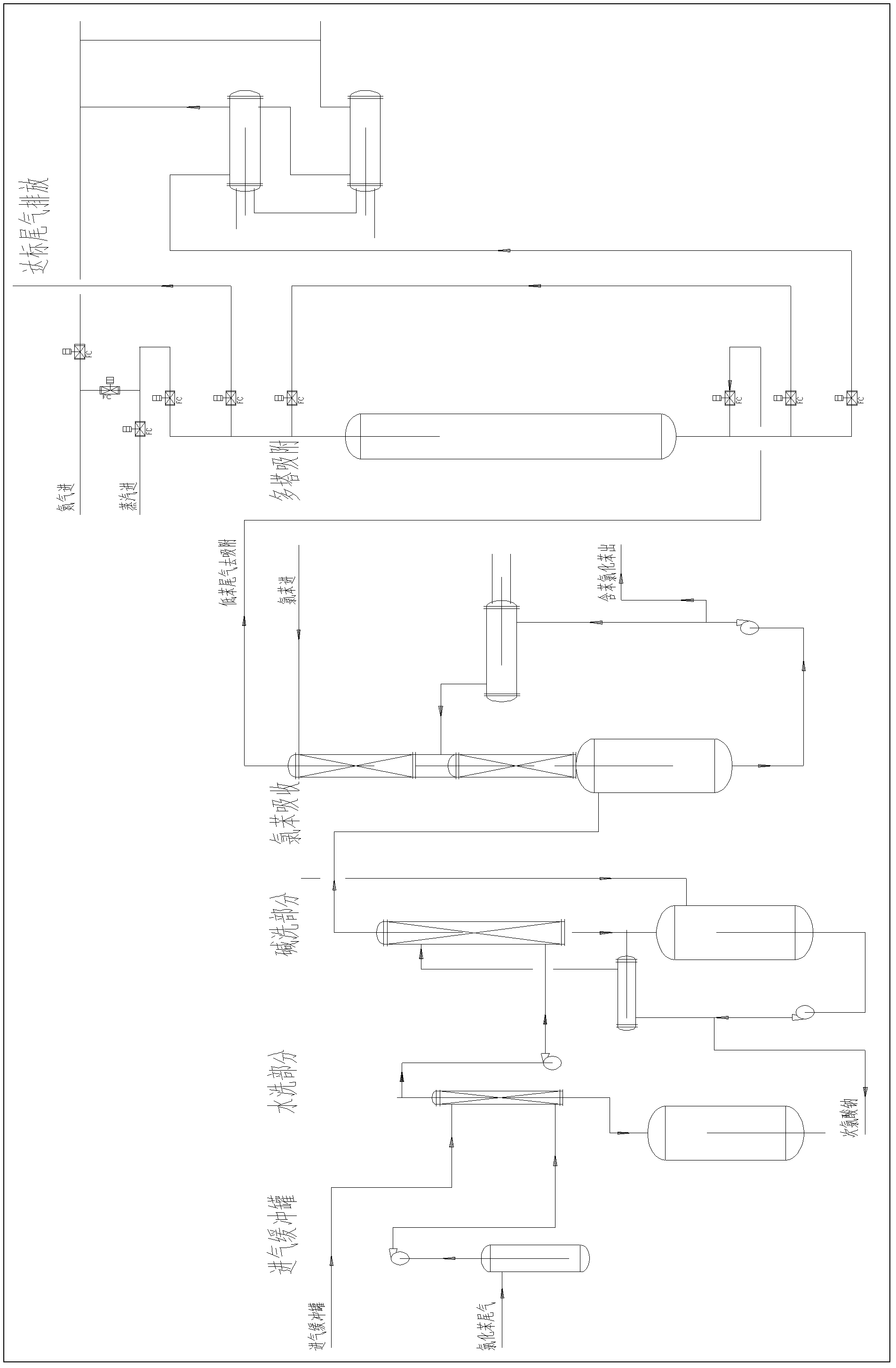

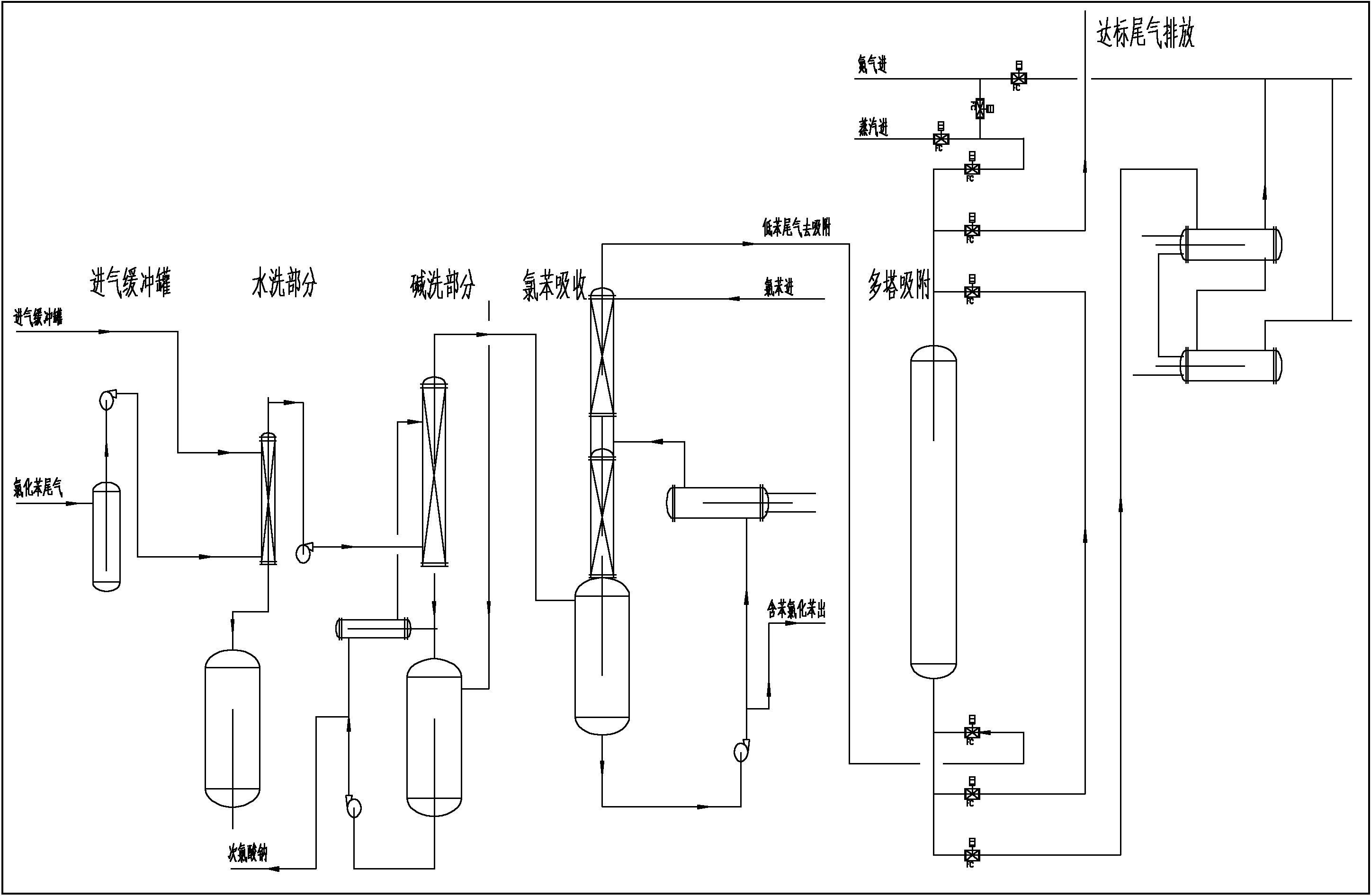

Image

Examples

Embodiment 1

[0019] Will contain benzene 7000-10000mg / m 3 After the chlorinated benzene tail gas passes through the water washing unit and alkali washing unit, it is sent to the benzene absorption unit by the fan, and then the tail gas enters the temperature swing adsorption system containing adsorbents. Benzene and chlorinated benzene organic gases are absorbed by the adsorbent, and the rest of the inert gases are discharged up to the standard The absorbent in the benzene absorption unit is chlorinated benzene.

[0020] Washing unit: 7000-10000 mg / m of benzene 3 The chlorinated benzene tail gas first enters the intake buffer tank, and then enters the dilute acid tower to be absorbed by water spray countercurrent, and the absorption liquid is merged into the dilute acid tank. The amount of water sprayed on the top of the washing tower is adjusted according to the acid concentration in the dilute acid tank, normally controlled at 1200-3000 liters / hour, and the temperature is controlled at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com