Thermally treated active carbon and preparation method thereof

A technology of activated carbon and high temperature treatment, applied in the field of materials science, can solve the problems of reducing the specific surface area and pore volume of activated carbon, destroying the pore distribution of the carrier, unfavorable dispersion of active metals and additives, and achieving low carbon loss on ignition and large porosity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

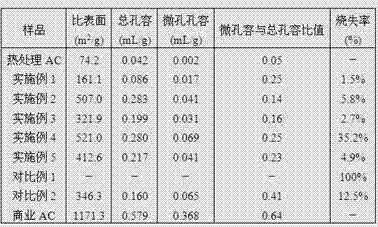

Examples

Embodiment 1

[0014] Take 4g of commercial activated carbon and place it in argon at 1850°C for 1 hour, crush it to 12-16 mesh, impregnate it in KOH solution until the mass ratio of KOH:C is 0.5:1, and dry it at 120°C for 4 hours. Place the sample in a tube furnace, expand the pores at 700°C for 2 hours in 200 mL / min of nitrogen, cool to room temperature in the above atmosphere, and wash 5 times with 20 mL of dilute hydrochloric acid (0.01 moL / L) , and then washed with distilled water until the washing solution is neutral and free of acidic ions, and then dried in an oven at 120 for 12 hours.

Embodiment 2

[0016] Example 1 was repeated, except that the time of the hole enlargement treatment was extended from 2 hours to 20 hours.

Embodiment 3

[0018] Repeat Example 1, just change KOH to KOH and K 2 CO 3 Mixture (KOH and K 2 CO 3 The mass ratio is 1:1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com