Alkene epoxidation method

A technology of epoxidation reaction and olefin, which is applied in the direction of organic chemistry, can solve the problems of low selectivity of propylene oxide and low conversion rate of hydrogen peroxide, etc., reduce equipment cost, shorten production cycle, and overcome the problem of low selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

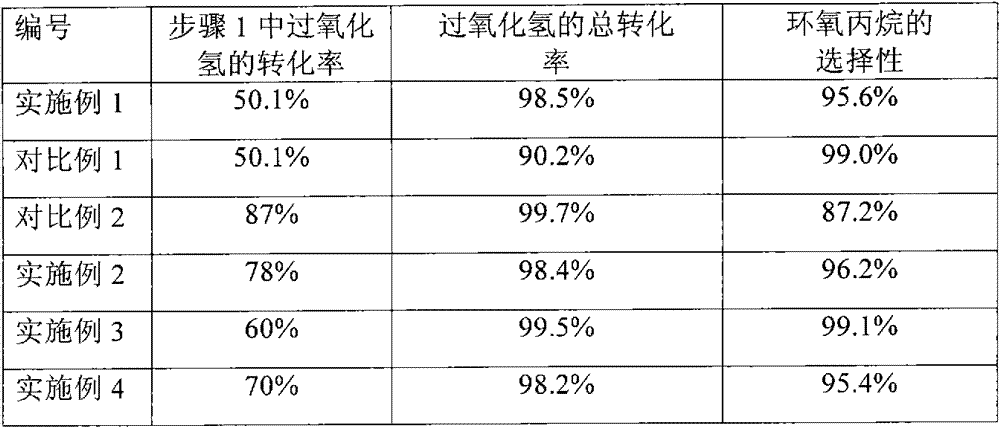

Embodiment 1

[0040] (1) The titanium-silicon molecular sieve-shaped catalyst was loaded in a fixed-bed reactor (purchased from Penglai Luhao Chemical Machinery Co., Ltd.), and the loading amount of the catalyst was 15 ml. A first mixed material containing propylene, methanol and hydrogen peroxide is introduced into the fixed bed reactor, wherein, in the first mixed material, the molar ratio of methanol, propylene and hydrogen peroxide is 4:4:1. The conditions of the reaction include: the temperature is 35°C, the pressure is 1MPa, and the volume space velocity of the first mixed material is 0.5h -1 , adjust the pH=5 of the first mixture material with ammoniacal liquor, detect the amount of hydrogen peroxide in the mixture after the reaction by iodometric method, and calculate the conversion ratio of hydrogen peroxide according to the calculation formula (1) shown above, the result As shown in Table 1. And detect the amount of propylene oxide generated in the step (1) by the chromatographic...

Embodiment 2

[0047] (1) The titanium-silicon molecular sieve-shaped catalyst was loaded in a fixed-bed reactor (purchased from Penglai Luhao Chemical Machinery Co., Ltd.), and the loading amount of the catalyst was 15 ml. A first mixed material containing propylene, methanol and hydrogen peroxide is introduced into the fixed bed reactor, wherein, in the first mixed material, the molar ratio of methanol, propylene and hydrogen peroxide is 10:3:1. The conditions of the reaction include: the reaction temperature is 75°C, the reaction pressure is 4MPa, and the volume space velocity of the first mixed material is 6h -1 , adjust the pH=7 of the first mixture material with ammoniacal liquor, detect the amount of hydrogen peroxide in the mixture after the reaction by iodometric method, and calculate the conversion rate of hydrogen peroxide according to the calculation formula (1) shown above, the result is as follows Table 1 shows. And detect the amount of propylene oxide generated in the step (1...

Embodiment 3

[0050] (1) The titanium-silicon molecular sieve-shaped catalyst was loaded in a fixed-bed reactor (purchased from Penglai Luhao Chemical Machinery Co., Ltd.), and the loading amount of the catalyst was 15 ml. A first mixed feed containing propylene, methanol and hydrogen peroxide is introduced into the fixed bed reactor, wherein, in the first mixed feed, the molar ratio of methanol, propylene and hydrogen peroxide is 8:0.8:1. The conditions of the reaction include: the reaction temperature is 50°C, the reaction pressure is 3MPa, and the volume space velocity of the first mixed material is 5h -1 , adjust the pH=6 of the first mixture material with ammoniacal liquor, detect the amount of hydrogen peroxide in the mixture after the reaction by iodometric method, and calculate the conversion rate of hydrogen peroxide according to the calculation formula (1) shown above, the result is as follows Table 1 shows. And detect the amount of propylene oxide generated in the step (1) by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com