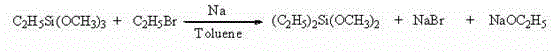

Preparation method of diethyldimethoxysilane

A technology of diethyldimethoxysilane and ethyltrimethoxysilane, which is applied in the field of synthesis of the compound diethyldimethoxysilane, and can solve problems such as by-products and difficulties of triethylmethoxysilane , to achieve the effects of improved controllability, good selectivity, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a dry 250mL four-necked flask equipped with a reflux condenser, a mechanical stirrer and a Pt-100 platinum resistor, add 20g (0.2171 mol) of toluene, 119.8g (0.7973 mol) of ethyltrimethoxysilane, and add 12.7 g (0.5524 mol) freshly cut sodium flakes, heat up to 109°C, and beat the sodium flakes into sodium sand; within 3.5 hours, add 29.5g (0.2707 mol) bromoethane into the reaction system through the bottom tube to control the reaction The temperature is between 107~111°C. After the dropwise addition, continue to react under reflux for 3.5h. After cooling to 18.4°C, slowly add 5.0mL (0.0857 mol) ethanol to neutralize the excess metallic sodium; then mix 8.7g ( 0.0674 mol) dimethyl dichlorosilane was added dropwise to the mixture within 1.5h to neutralize the generated sodium alkoxide; after the dropwise addition was completed, the reaction was continued at this temperature for 3h. Then the reaction mixture was suction-filtered under reduced pressure to obtain 98.8 g ...

Embodiment 2

[0024]In a dry 500mL four-neck flask equipped with a reflux condenser, a mechanical stirrer and a Pt-100 platinum resistor, add 20g (0.2171 mol) of toluene, 159.8g (1.0636 mol) of ethyltrimethoxysilane, and add 12.0 g of g (0.5220 mol) freshly cut sodium flakes, heated up to 103°C, and beat the sodium flakes into sodium sand; within 2.5 hours, add 29.8g (0.2734mol) bromoethane into the reaction system through the bottom tube to control the reaction The temperature is between 101~105°C. After the dropwise addition, continue the reaction under reflux for 2.5h. After cooling to 38°C, slowly add 4.0mL (0.0685 mol) ethanol to neutralize the excess metallic sodium; then mix 7.8g ( 0.0604 mol) dimethyl dichlorosilane was added dropwise to the mixture within 2.5h to neutralize the generated sodium alkoxide; after the dropwise addition was completed, the reaction was continued at this temperature for 2h. Then the reaction mixture was suction-filtered under reduced pressure to obtain 10...

Embodiment 3

[0026] In a dry 500mL four-necked flask equipped with a reflux condenser, a mechanical stirrer and a Pt-100 platinum resistance, add 199.6g (1.3285 mol) of ethyltrimethoxysilane, and add 12.4g (0.5394 mol) of freshly cut The sodium flakes were heated up to 103 °C, and the sodium flakes were beaten into sodium sand; within 2.5 hours, 29.1 g (0.2671 mol) of bromoethane was added to the reaction system through the bottom tube, and the reaction temperature was controlled between 107 and 111 °C After the dropwise addition, continue to react under reflux for 5 h. After cooling to 40°C, slowly add 6.0 mL (0.1028 mol) of ethanol to neutralize the excess metal sodium; then add 20.0 g (0.1550 mol) of dimethyl di Chlorosilane was added dropwise to the mixture within 3.5h to neutralize the generated sodium alkoxide; after the dropwise addition was completed, the reaction was continued at this temperature for 1h. Then the reaction mixture was suction-filtered under reduced pressure to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com