A kind of sponge composite type organic solvent absorbent and preparation method thereof

An organic solvent and composite technology, which is applied in the field of sponge composite organic solvent absorbent and its preparation, can solve the problems of being unsuitable for handling trace amounts of organic solvents, and the preparation process of the absorbent is complicated, and achieves improved surface hydrophobicity and lipophilicity and oil-water selection. The effect of increasing the surface roughness of the skeleton and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

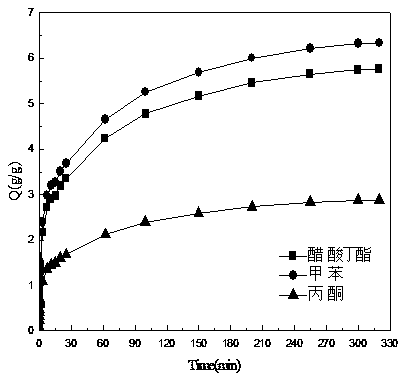

Examples

Embodiment 1

[0045] A method for preparing a sponge composite organic solvent absorbent includes the following steps:

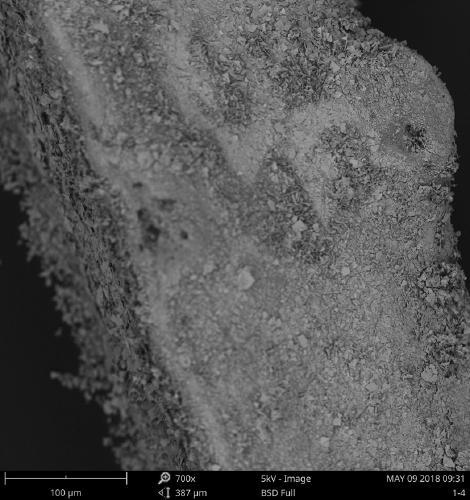

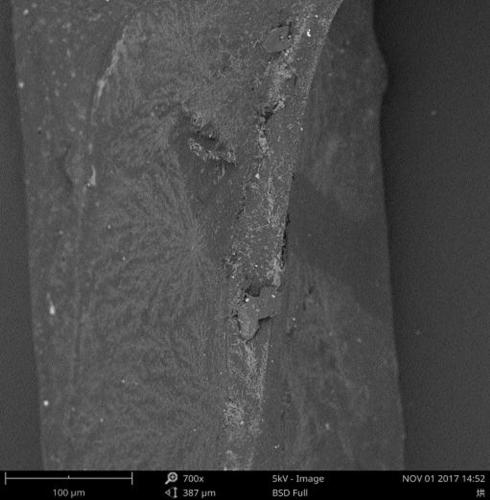

[0046] (1) After immersing the polyurethane sponge with NaOH (10wt%) aqueous solution, heating it at 60°C for 1.5h, then washing with deionized water and drying for use;

[0047] (2) Immerse the alkali-treated polyurethane sponge in step (1) in the acrylic resin emulsion for 1.5 hours, then take it out and let it dry naturally at room temperature, and repeat the process twice;

[0048] (3) Put the polyurethane sponge loaded with acrylic resin in step (2) in a 150°C constant temperature drying oven to cure for 2 hours to obtain an acrylic resin / polyurethane sponge composite material;

[0049] (4) The acrylic resin / polyurethane sponge composite material is 5mmol / L -1 The zinc acetate ethanol solution is impregnated and dried to obtain a ZnO seed crystal / acrylic resin / polyurethane sponge composite material;

[0050] (5) Prepare 50mmol / L separately -1 Zinc nitrate aqueous solution and ...

Embodiment 2

[0062] A method for preparing a sponge composite organic solvent absorbent includes the following steps:

[0063] (1) Immerse the polyurethane sponge with KOH (5wt%) aqueous solution and heat it at 55°C for 1 hour, then wash it with deionized water and dry it for later use;

[0064] (2) Immerse the alkali-treated polyurethane sponge in step (1) in the acrylic resin emulsion for 1.5 hours, then take it out and let it dry naturally at room temperature, and repeat the process 3 times;

[0065] (3) Put the polyurethane sponge loaded with acrylic resin in step (2) in a constant temperature drying oven at 120°C for 2.5 hours to cure to obtain an acrylic resin / polyurethane sponge composite material;

[0066] (4) The ratio of acrylic resin / polyurethane sponge composite material to 15mmol / L -1 The zinc acetate ethanol solution is impregnated and dried to obtain a ZnO seed crystal / acrylic resin / polyurethane sponge composite material;

[0067] (5) Prepare 150mmol / L separately -1 ZnSO 4 Zinc nitrat...

Embodiment 3

[0070] A method for preparing a sponge composite organic solvent absorbent includes the following steps:

[0071] (1) After immersing the polyurethane sponge with KOH (15wt%) aqueous solution, heating it at 45°C for 0.5h, then washing with deionized water and drying for use;

[0072] (2) Immerse the alkali-treated polyurethane sponge in step (1) in the acrylic resin emulsion for 1 hour, then take it out and dry it naturally at room temperature, and repeat the process twice;

[0073] (3) Put the polyurethane sponge loaded with acrylic resin in step (2) in a constant temperature drying oven at 100°C for 1.5 hours to obtain an acrylic resin / polyurethane sponge composite material;

[0074] (4) The acrylic resin / polyurethane sponge composite material is 9mmol / L -1 The zinc acetate ethanol solution is impregnated and dried to obtain a ZnO seed crystal / acrylic resin / polyurethane sponge composite material;

[0075] (5) Prepare 90mmol / L separately -1 ZnSO 4 Zinc nitrate aqueous solution and 45mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com