Process and device for continuously gasifying biomass and simultaneously removing tar in moving bed

A moving bed, biomass technology, applied in the fields of activation, biomass gasification and carbon, can solve the problems of reduced operability, large difference in furnace temperature, partial burning, etc., to achieve the effects of improved economy, energy saving and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

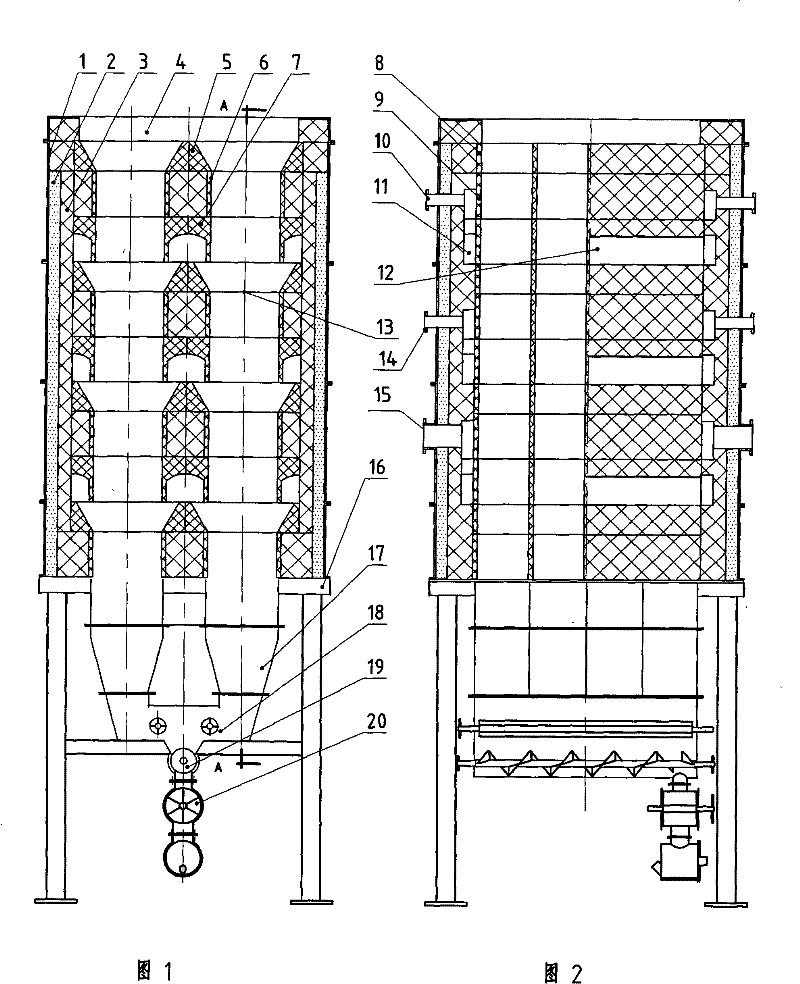

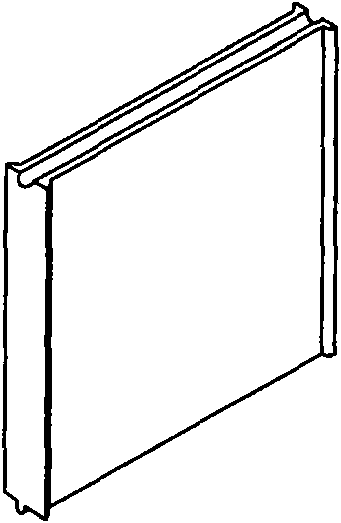

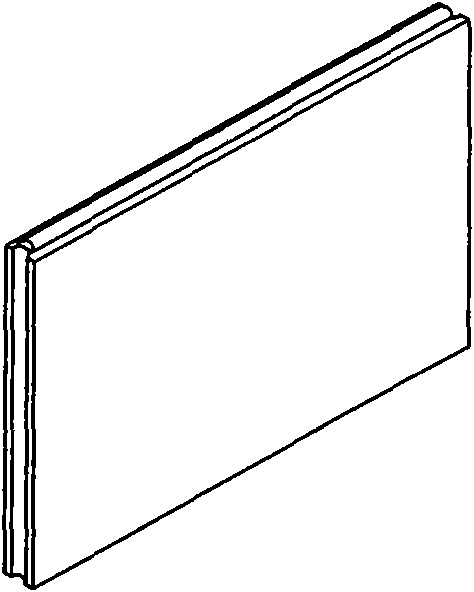

[0013] The method of the present invention needs to be implemented through a specific gasification furnace. Although there are more than one type of furnace that can be implemented, it is more suitable as figure 1 , figure 2 The shown "pipe row moving bed gasification coke removal furnace" is assembled with uniquely designed special-shaped refractory bricks stacked and assembled into a furnace core. The furnace core brick can be used as image 3 , 4, 5, 6, and 7 show straight bricks (6), horizontal bricks (9), oblique bricks (5), inclined bricks (8), and channel bricks (7), which are five uniquely designed special-type refractory bricks. The bricks are stacked and assembled into rows of reaction tubes (13), and the straight bricks (6) are in the shape of a rectangular thick plate, with a semicircular groove on the upper side of the "long x thick" and a groove on the lower side of the "long x thick". Semicircle convex ribs, two wide sides of the upper side of "length × widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com