Dual complementary metal oxide semiconductor (CMOS) image sensor pixel unit with high filling factor, and working method

An image sensor, pixel unit technology, applied in image communication, TV system components, electrical components, etc., can solve the problems of sensitivity, signal-to-noise ratio fill factor degradation, etc., achieve convenient control, reduce off-state leakage current, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The AMIS (ON Semiconductor) CMOS technology and rules with a thickness of 0.35um are adopted, so that each pixel unit only needs a 2T-APS test structure with one polysilicon layer and five metal layers, and each pixel unit size is 7um×7um.

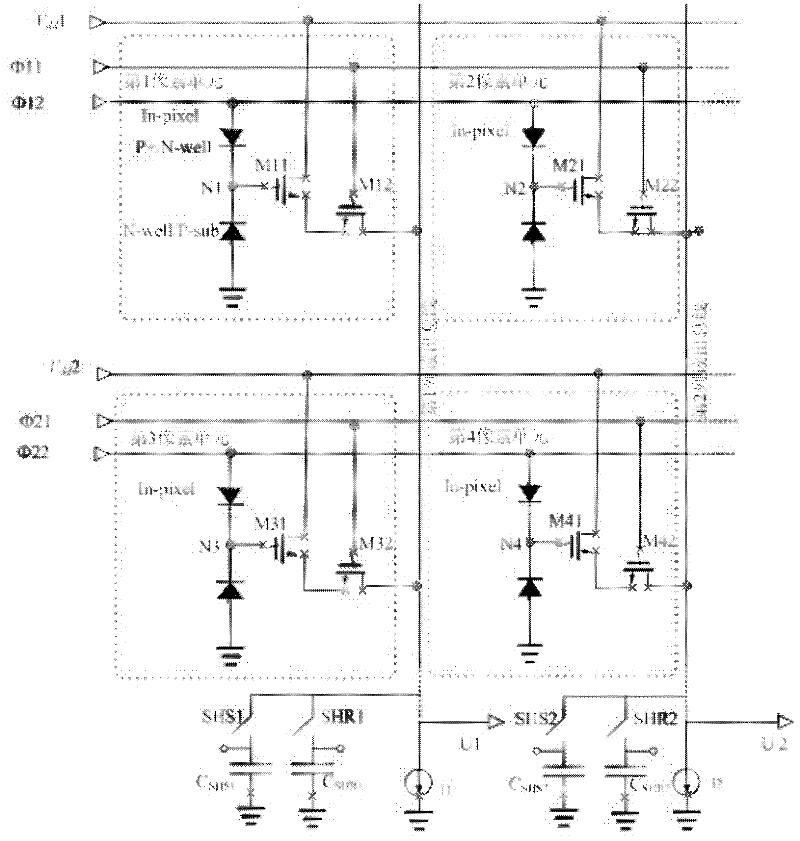

[0039] The chip of this embodiment specifically adopts the simplest 2T-APS pixel array of 2×2 pixel units, and its equivalent circuit is as follows figure 2 As shown, the corresponding layout is as Figure 4 shown.

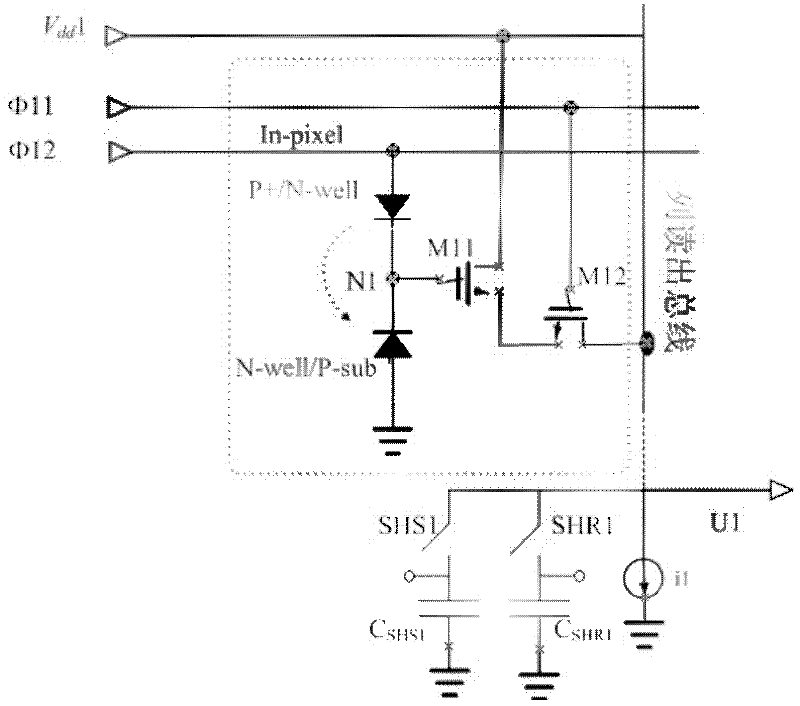

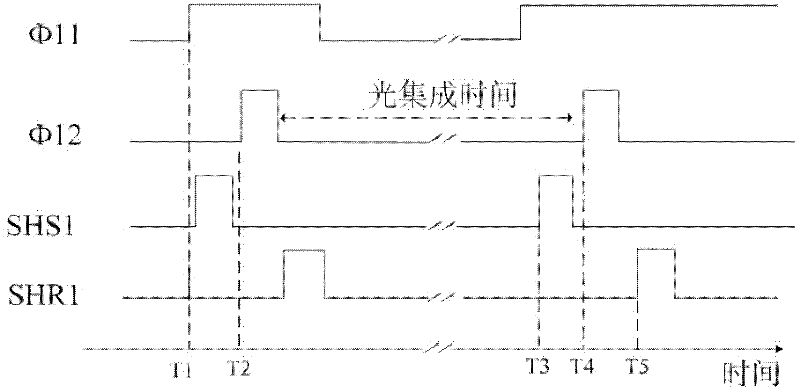

[0040] The circuit structure of each pixel unit of the pixel array chip, the equivalent circuit is as figure 1 As shown, wherein: N1 is a diode with a P+ / N-Well / P-sub structure, and its P+ terminal is electrically connected to the reset control signal Φ11; M11 is a source follower transistor, and its base is electrically connected to the P+ / N- Diode N1 of Well / P-sub structure, the collector is electrically connected to the bias voltage Vdd1; M12 is a selection transistor, the emitter is electrically connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com