Device for detecting an analyte

一种被测物、计量装置的技术,应用在固态pH探头组装件和计量装置,测量pH的装置,pH探头组装件,pH测量系统领域,能够解决玻璃电极易碎、无人值守、危险的环境等问题,达到廉价构造、容易构造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

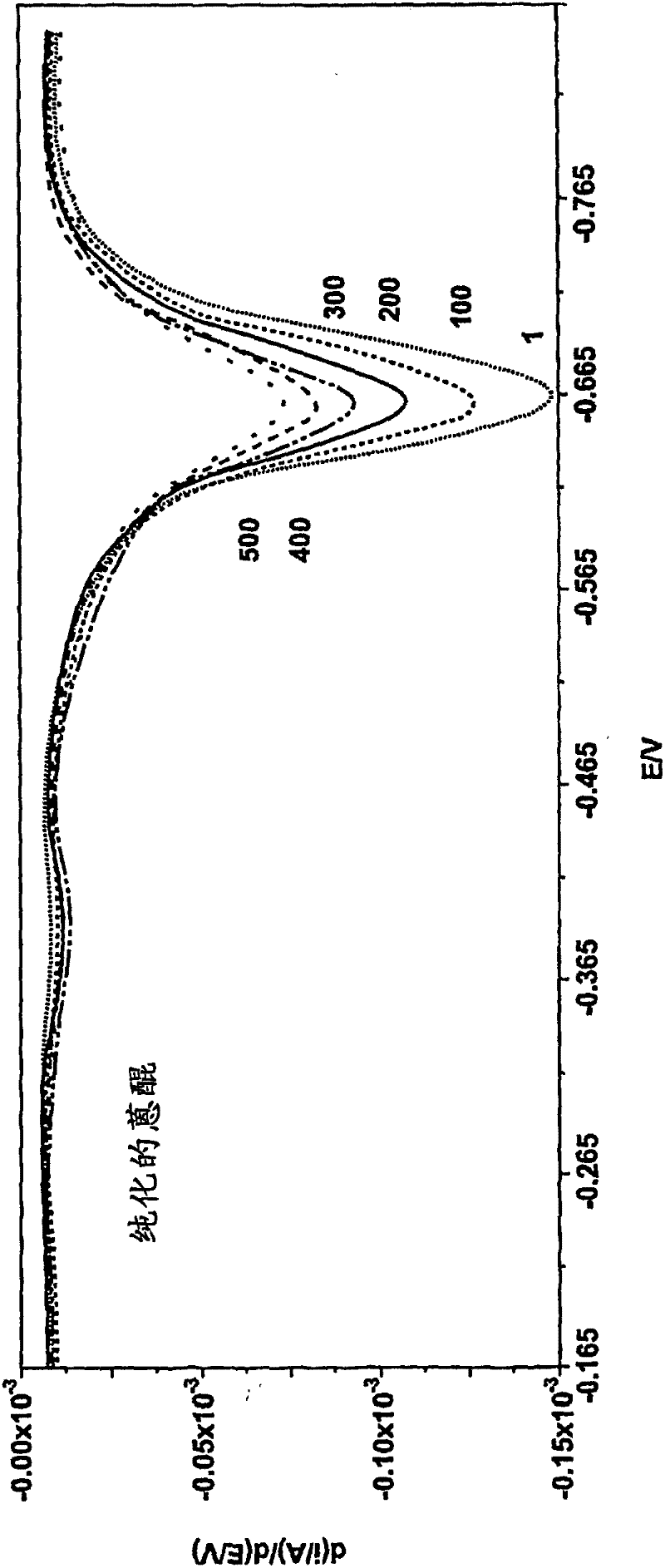

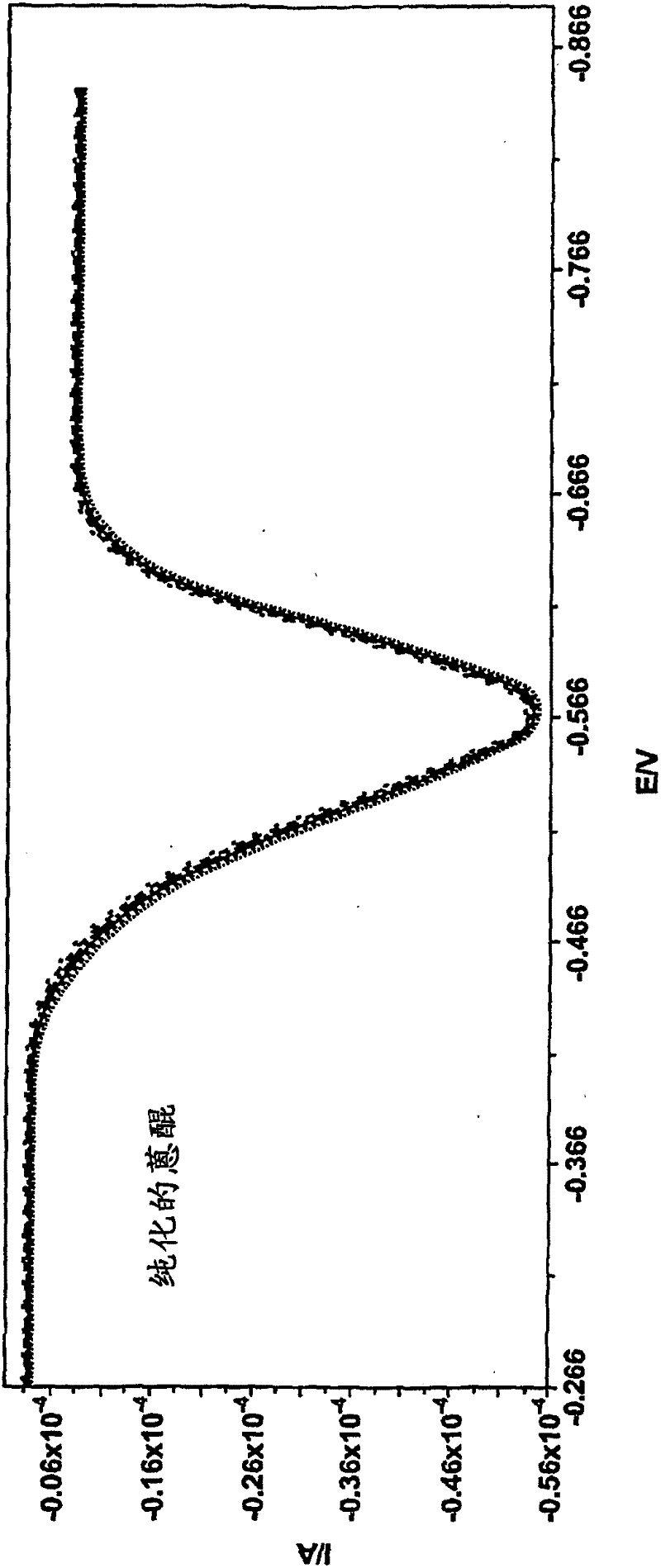

[0169] WE ASM Example 1: By comparatively studying the signal intensity and signal peak position stability in AQ and selected AQ derivatives, evaluating the sensor life and the accuracy that changes with the sensor life

[0170] To determine the improvement in accuracy over lifetime and sensor lifetime for a range of sensor constructs, the signal decay rate vs. Study on the change of signal peak position: 2-carboxy AQ, 2-BOC ethylenediamine AQ, 5,12-naphthoquinone, 1-acetylamido AQ and 2-(β-naphthol)methylanthraquinone.

[0171] Synthesis of 2-(β-naphthol)methylanthraquinone

[0172] 2-(Bromomethyl)anthraquinone (0.225 g, 0.747 mmol) and 2-hydroxynaphthalene (0.118 g, 0.822 mmol) were taken up in acetone (10 mL). K2CO3 (0.134 g, 0.971 mmol) was added in one portion and the reaction vial was sealed. The reaction mixture was heated in a heating block (65° C.) while stirring overnight. The next morning, the reaction mixture was cooled to ambient temperature. Deionized water w...

Embodiment 4

[0199] Example 4: Fabrication of WE with Luer connector

[0200] A preferred WE of the present invention is produced as follows. refer to Figure 19 , insert the gold-plated spring 106 into the tip housing 36 and allow it to rest on a ledge in the tip housing. A portion of a graphite rod 42 (0.120" diameter, Graphite Sales, Inc.) was inserted into a plastic housing 36 machined to accommodate less than its full length but the entire diameter of the rod at all points except near one end of the housing. In this arrangement, the rod 42 is in direct electrical contact with the spring 106. The annular gap 124 is filled with epoxy (Epotek, Billerica, MA) and cured according to the epoxy manufacturer's instructions. The protruding portions of the rod-epoxy constructs were then sanded first with 220 grit sandpaper and then with 1200 grit sandpaper to obtain a flat plastic-epoxy-graphite surface.

[0201] The freshly sanded tip was dusted with a stream of nitrogen to remove particles...

Embodiment 1

[0222] Example 1: pH Sensor Assembly

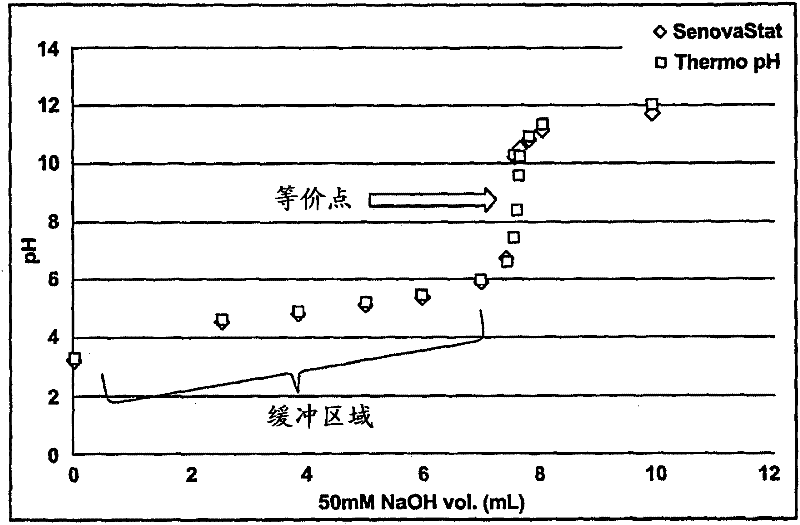

[0223] now refer to Figure 14-19 , providing a probe assembly 201 comprising various electrodes arranged in a coaxial configuration. In some embodiments, such as Figure 15 and Figure 18 As shown, the probe assembly 201 includes a working electrode (WE) comprising a redox-active analyte-sensitive material (ASM), a counter electrode (CE) comprising a conductive carbon fiber tube, and a chloride electrode (CE) comprising a chloride surrounded by an electrolyte. Reference electrode (RE) of silver wire. The pH measurement system 101 directly measures the proton concentration in the sample solution by electrochemically initiating a reversible chemical reaction on the ASM of the WE. Once the WE, CE and RE are immersed in the sample solution, a voltage is swept across the CE, causing redox reactions in the ASM of the WE, thereby gaining or losing electrons. The resulting electron flow is recorded by the pH processor module.

[0224] In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com