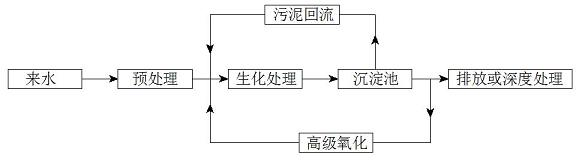

Biochemical treatment/advanced oxidation treatment coupled sewage treatment technique

An advanced oxidation and sewage treatment technology, applied in the field of water treatment, can solve the problems of large interference factors, insignificant advantages of advanced oxidation process, increased investment and operational complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

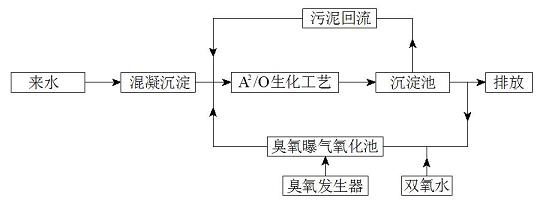

Embodiment 1

[0010] A fine chemical company mainly produces various paper-making additives and dyeing and finishing auxiliaries, and paper-making additives account for more than 90% of the company's production capacity. The company uses "coagulation sedimentation-A 2 / O" process to treat production wastewater, although the residence time of wastewater in the biochemical system pool is as long as 6 days, the effluent COD Cr It is still unable to meet the requirement of 500mg / L.

[0011] By analyzing the information provided by the company, it was found that the paper-making additives it produces are all high molecular polymers. Due to the inevitable problem of incomplete polymerization during the polymerization reaction, a small amount of polymers with relatively low molecular weights will be produced, and these polymers with relatively low molecular weights will all enter the wastewater. Polymers with relatively low molecular weight can neither be removed by coagulation precipitation nor...

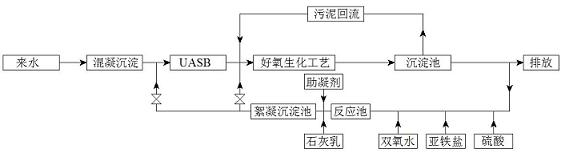

Embodiment 2

[0014] A large petrochemical company mainly produces butadiene rubber, phenol, acetone and other chemical products. The waste water discharged by the company during the production process is firstly pretreated separately by the workshop level treatment device, and then collected to the adjustment pool of the company's sewage treatment station. The company's total process wastewater discharge is 1579.2m 3 / d, due to the high concentration of organic pollutants in this sewage, a UASB upflow anaerobic reactor was installed after coagulation and sedimentation, followed by a contact oxidation process, and the process effluent was diluted with river water before being discharged. The amount of dilution water was about 4133m 3 / d. Although it can produce water COD after dilution Cr Reaching the discharge standard of 100mg / L, but significantly increased wastewater discharge and COD Cr The total emissions are not in line with the energy conservation and emission reduction policies a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com