Straw cement-based microporous building material and preparation method thereof

A building material, cement-based technology, applied in the field of building materials, can solve the problems of high thermal conductivity, high bulk density of formed sheets, low thermal conductivity of manufacturing bulk density, etc., and achieves the effect of small and uniform pores and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

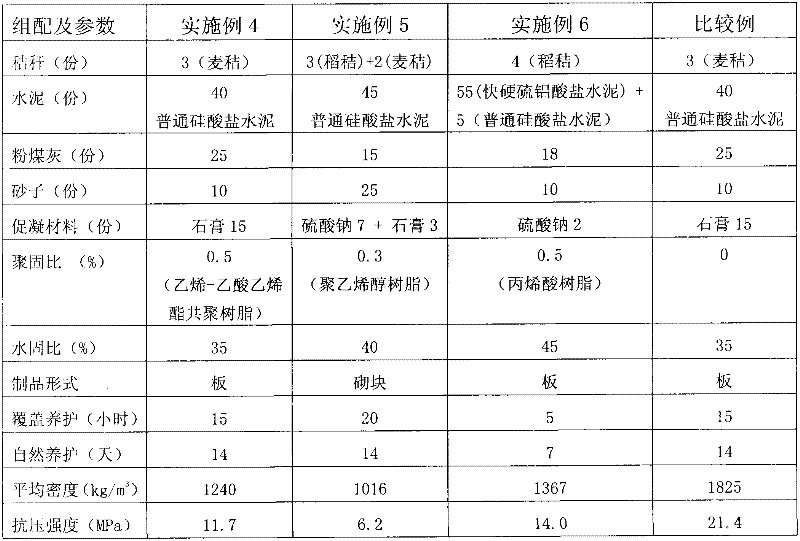

Examples

preparation example Construction

[0035] The preparation method of the straw cement-based microporous building material provided by the present invention may comprise the following steps:

[0036] 1) Prepare the polymer aqueous solution, and measure the remaining water according to the proportioning ratio;

[0037] 2) Mix 90-100% of cement, fly ash, sand, coagulation-accelerating materials and the remaining water and stir evenly;

[0038] 3) Add straw while stirring, so that it is evenly dispersed in the above-mentioned mixture;

[0039] 4) Stir continuously, gradually add the polymer aqueous solution, and then add the remaining water to form a mixture containing uniform micro-bubbles, which is the straw cement-based microporous building material.

[0040] Using the above-mentioned straw cement-based microporous building materials can directly manufacture building material products, including the following steps:

[0041] Step 1: pour the above-mentioned mixture into the model, and cover and cure; the coveri...

Embodiment 1

[0046] The solid material mix ratio of straw cement-based microporous building materials (by weight, the unit of "part" can be "gram" or "kilogram"): 2.3 parts of wheat straw powder, 44.5 parts of cement, 21.6 parts of fly ash, sand 21.6 parts, 10 parts of coagulation-accelerating materials (gypsum and rapid-hardening sulfoaluminate cement each account for 50%); the poly-solid ratio is 0.2%, and the water-solid ratio is 36%.

[0047] Preparation of straw cement-based microporous building materials and test blocks, the specific method includes the following steps:

[0048] 1) Take by weighing 23 grams of wheat straw powder, 445 grams of ordinary Portland cement with a strength grade of 42.5, 216 grams of fly ash, 216 grams of sand, 50 grams of gypsum, and 50 grams of quick-hardening sulfoaluminate cement;

[0049] 2) Measure 40 milliliters of polyvinyl alcohol resin polymer solution with a solid content of 5% (excluding the volume of the solid polymer, the water content is calc...

Embodiment 2

[0058] The solid material mix ratio of straw cement-based microporous building materials: 4.3 parts of wheat straw crushed powder, 55.2 parts of cement, 17.0 parts of fly ash, 21.5 parts of sand, 2.0 parts of coagulation-accelerating material; poly-solid ratio 0.4%, water-solid ratio 38 %.

[0059] Preparation of straw cement-based microporous building materials and test blocks, the specific method includes the following steps:

[0060] 1) Take by weighing 43 grams of wheat straw powder, 552 grams of rapid-hardening sulfoaluminate cement with a strength grade of 42.5, 170 grams of fly ash, 215 grams of sand, and 20 grams of sodium sulfate;

[0061] 2) Measure 80 milliliters of acrylic resin polymer solution with a solid content of 5% (excluding the volume of the solid polymer, the water content is calculated as 80 milliliters), and another 300 milliliters of water;

[0062] 3) Put 552 grams of fast-hardening sulfoaluminate cement with a strength grade of 42.5, 170 grams of fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com