Preparation method of powdery emulsion explosive oil phase material

A technology of powdery emulsified explosives and oil phase, which is applied in explosives, non-explosive/non-thermal agent components, offensive equipment, etc., can solve the problems of expensive emulsifiers, achieve stable explosive quality, improve explosive performance, and continuous compaction Sexually Enhanced Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

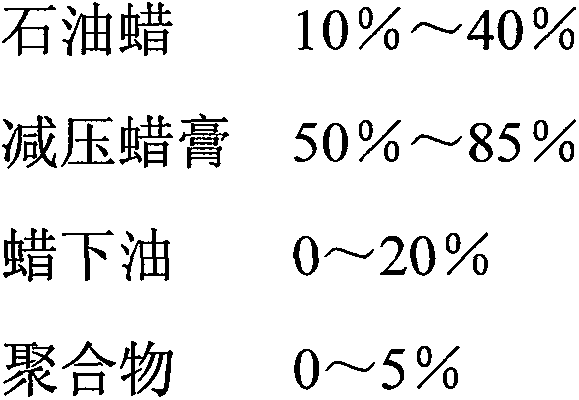

Method used

Image

Examples

Embodiment 1

[0025] Heat and mix 200g of 58# semi-refined paraffin wax, 400g of minus three line wax paste, 300g of residual oil wax paste, 80g of wax base oil, 20g of PE and 1g of naphthenic acid cobalt, pour it into the reactor, and let it react with air at 160°C for 5 hour, the air flow rate is 25L / h, add 20g of phospholipids after oxidation, and continue to react for 1 hour.

Embodiment 2

[0027] Heat and mix 250g of 60# semi-refined paraffin, 450g of minus four line wax paste, 200g of residual oil wax paste, 90g of wax base oil, and 20g of PP, pour it into the reactor, slowly add 10g of hydrogen peroxide, and let air react at 170°C For 8 hours, the air flow rate was 30 L / h, and 10 g of phospholipids were added for oxidation, and the reaction was continued for 0.5 hours.

Embodiment 3

[0029] Heat and mix 200g of 62# semi-refined paraffin wax, 350g of second-line wax paste, 300g of residue wax paste, 120g of wax base oil, 30g of EVA and 4g of potassium permanganate, pour into the reactor, and react with air at 150°C for 4 hours , the air flow rate is 20L / h, add 40g of phospholipid after oxidation, and continue to react for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com