Skin wound healing material and manufacturing method thereof

A technology of healing materials and manufacturing methods, applied in the fields of medical science, bandages, absorbent pads, etc., can solve problems such as inconvenience, general products and methods do not have suitable structures and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

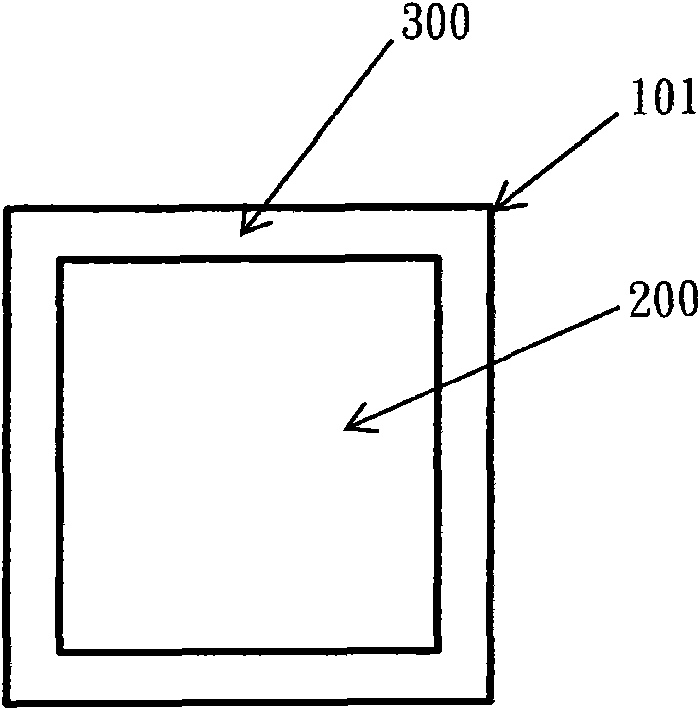

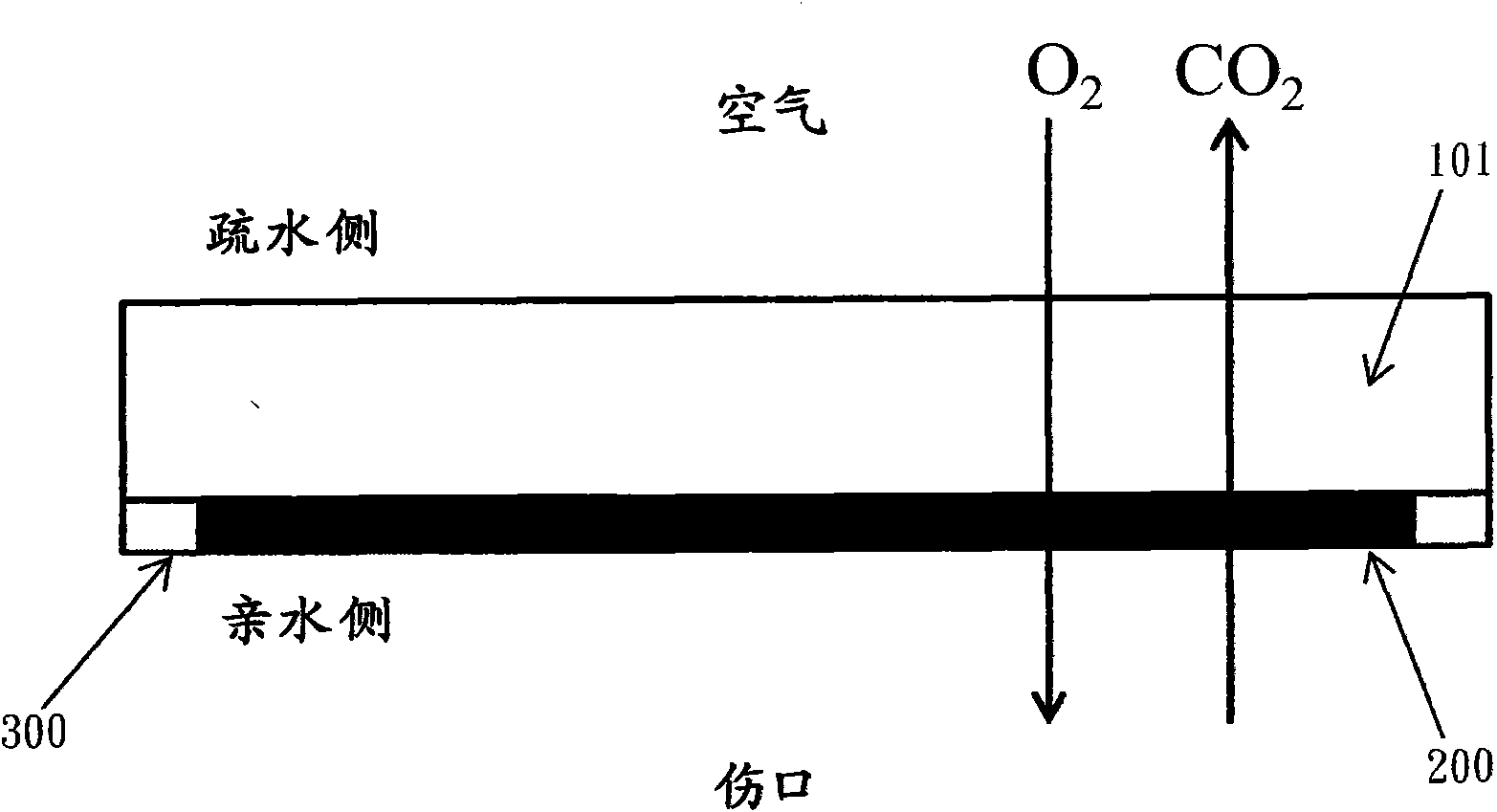

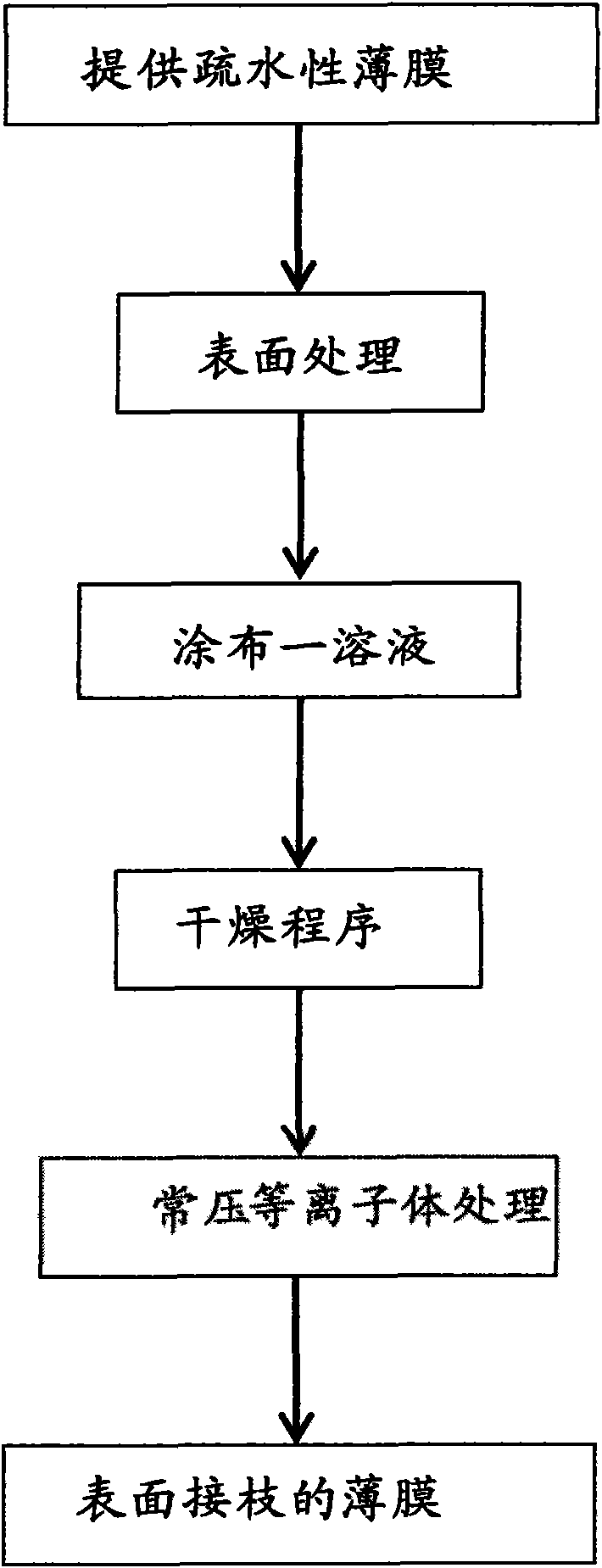

[0068] The first embodiment of the present invention discloses a skin wound healing material, which comprises: a fluorine-containing hydrophobic film with a first surface and a second surface opposite to each other, the hydrophobic film is gas permeable but liquid impermeable properties; at least one biocompatible macromolecule covalently bonded to a part of the first surface of the hydrophobic film; wherein the contact angle to water of the first surface formed with the biocompatible macromolecule is 40 degrees or less, more preferably 10 to 40 degrees, more preferably 20 to 30 degrees. When the contact angle to water is 20-30 degrees, the effect of leaving no scars is better. The second surface is hydrophobic, and its contact angle to water is more than 100 degrees.

[0069] In the above embodiment, the at least one biocompatible polymer is selected from polymers without charged groups, polymers containing diionic groups, and polymers containing pseudo-diionic groups. At l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Graft density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com