Electrochemical grinding method and device for cam surface of internal-combustion engine

An electrochemical grinding, cam surface technology, applied in grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems of cam grinding cracks, irregular cam contour lines, burns, etc., and achieve high finishing efficiency and technology. Simple equipment and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

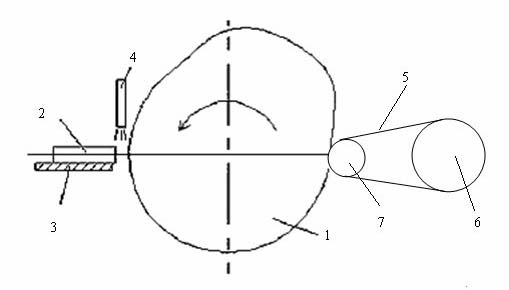

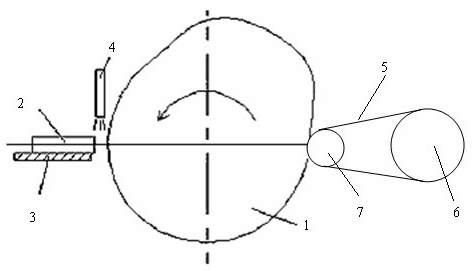

[0016] Such as figure 1 As shown, the entire internal combustion engine cam surface electrochemical compound abrasive belt grinding and finishing equipment is composed of a camshaft rotary motion system, an electrode motion system and an abrasive belt motion system.

[0017] The camshaft 1 is driven by the servo motor to rotate at a constant speed, the speed is 120r / min, and the camshaft is connected to the positive pole of the constant current DC power supply.

[0018] The electrode 2 is placed on the CNC table 3, and the servo motor drives the CNC table 3 to move back and forth, thereby driving the electrode 2 to move back and forth, and maintain a constant gap with the cam, the gap value is 5mm, and the electrode is connected to the negative pole of the constant current DC power supply .

[0019] A neutral electrolyte 4 is passed between the cam 1 and the electrode 2, and a constant DC voltage of 16V is applied between the cam 1 and the electrode 2.

[0020] The abrasive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com