Method for preparing electrolyte for vanadium battery

A vanadium battery and electrolyte technology, which is applied in the field of preparing electrolyte for vanadium batteries, can solve the problems of high cost, high investment cost, and unsuitability for large-scale industrial production and application, and achieves the convenience of production and manufacturing, saving production costs, and shortening the preparation time. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) 1170 grams of NH with a mesh number of 50 4 VO 3 After drying at 50°C for 1 hour, with 702 g NH 4 HCO 3 After mixing evenly, pour it into an alumina crucible, move it into a vacuum atmosphere furnace, and heat up to 250°C at a rate of 2°C / min for the first calcination. The calcination time is 1 hour, and then heat up to Carry out the second calcination at 650°C, and cool with the furnace after calcination for 3 hours. After the temperature in the furnace cools down to room temperature, take out the crucible and pour out the black V 2 o 3 Crystals with a mass of 755 grams. After crushing the crystals, pass through a 100-mesh sieve for later use.

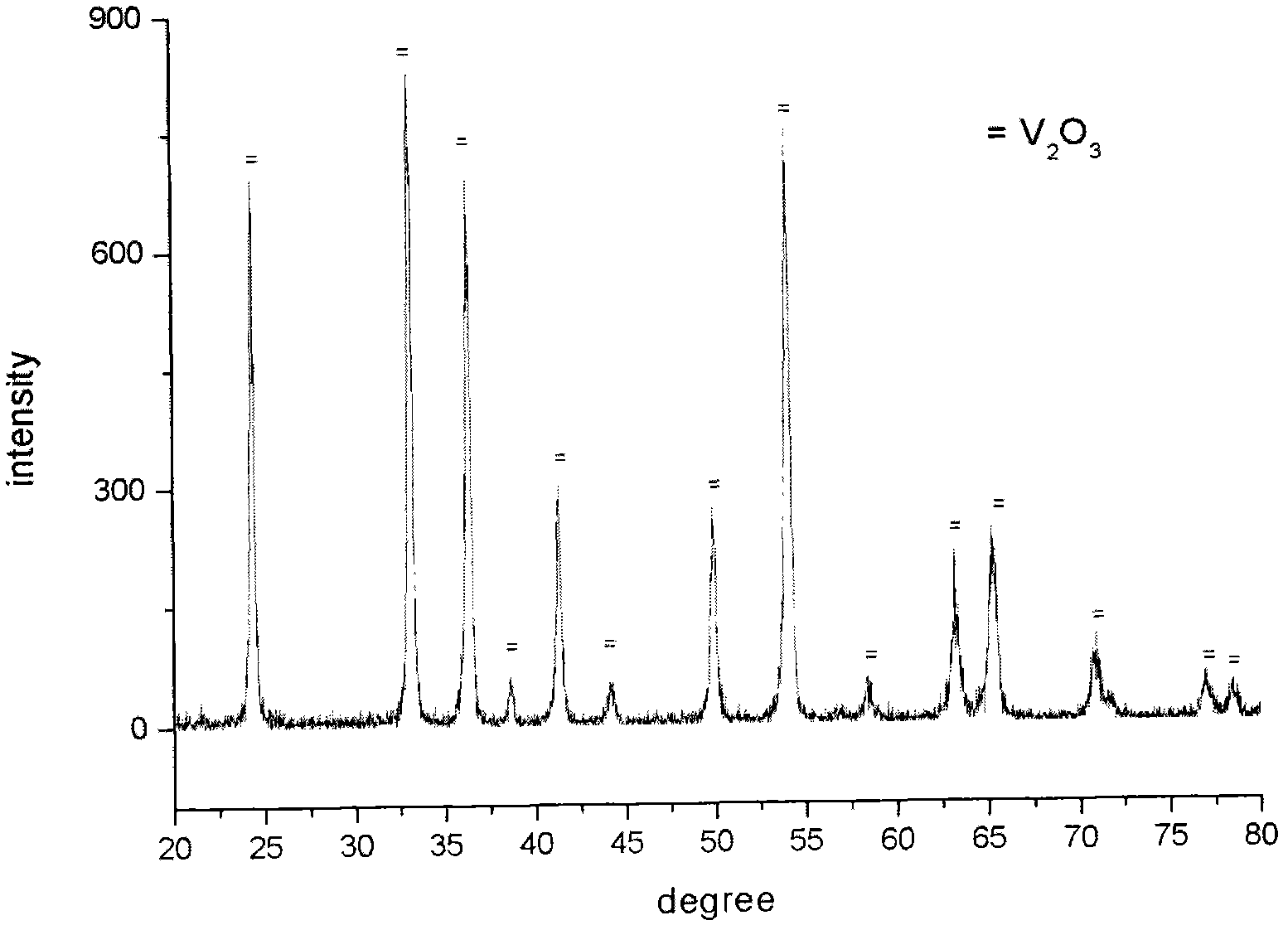

[0039] V obtained in this step 2 o 3 The XRD pattern of the powder is as follows figure 1 As shown, it can be seen from the figure that the structure of the compound is correct, which is V 2 o 3 Powder.

[0040] 2) Take 562 grams of step 1) gained 100 mesh V 2 o 3 Powder, added to 5 liters of 5.5M sulfuric acid...

Embodiment 2

[0044] 1) 1755 grams of NH with a mesh number of 200 4 VO 3 After drying at 150°C for 4 hours, with 1400 g NH 4 HCO 3 After mixing evenly, pour it into an alumina crucible, move it into a vacuum atmosphere furnace, heat up to 250°C at a rate of 10°C / min for the first calcination, and calcine for 3 hours, then raise the temperature to 650°C at a rate of 10°C / min °C for the second calcination, and after 6 hours of calcination, it was cooled with the furnace. After the temperature in the furnace cools down to room temperature, take out the crucible and pour out the black V 2 o 3 Crystal with a mass of 1130 grams. After crushing the crystals, pass through a 150-mesh sieve for later use.

[0045] V obtained in this step 2 o 3 The XRD pattern of powder and figure 1 There is no substantial difference, which proves that the structure of the product obtained in this step is correct, which is V 2 o 3 Powder, no longer described here.

[0046] 2) Take 562 grams of step 1) gai...

Embodiment 3

[0050] 1) Mix 1400 grams of NH with a mesh number of 100 4 VO 3 After drying at 120°C for 2 hours, with 1170 g NH 4 HCO 3 After mixing evenly, pour it into an alumina crucible, move it into a vacuum atmosphere furnace, and heat up to 250°C at a rate of 5°C / min for the first calcination, calcining for 2 hours, and then raise the temperature to 650°C at a rate of 5°C / min °C for the second calcination, and after 4 hours of calcination, it was cooled with the furnace. After the temperature in the furnace cools down to room temperature, take out the crucible and pour out the black V 2 o 3 Crystals with a mass of 903 grams. After crushing the crystals, pass through a 50-mesh sieve for later use.

[0051] V obtained in this step 2 o 3 The XRD pattern of powder and figure 1 There is no substantial difference, which proves that the structure of the product obtained in this step is correct, which is V 2 o 3 Powder, no longer described here.

[0052] 2) Take 562 grams of step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com