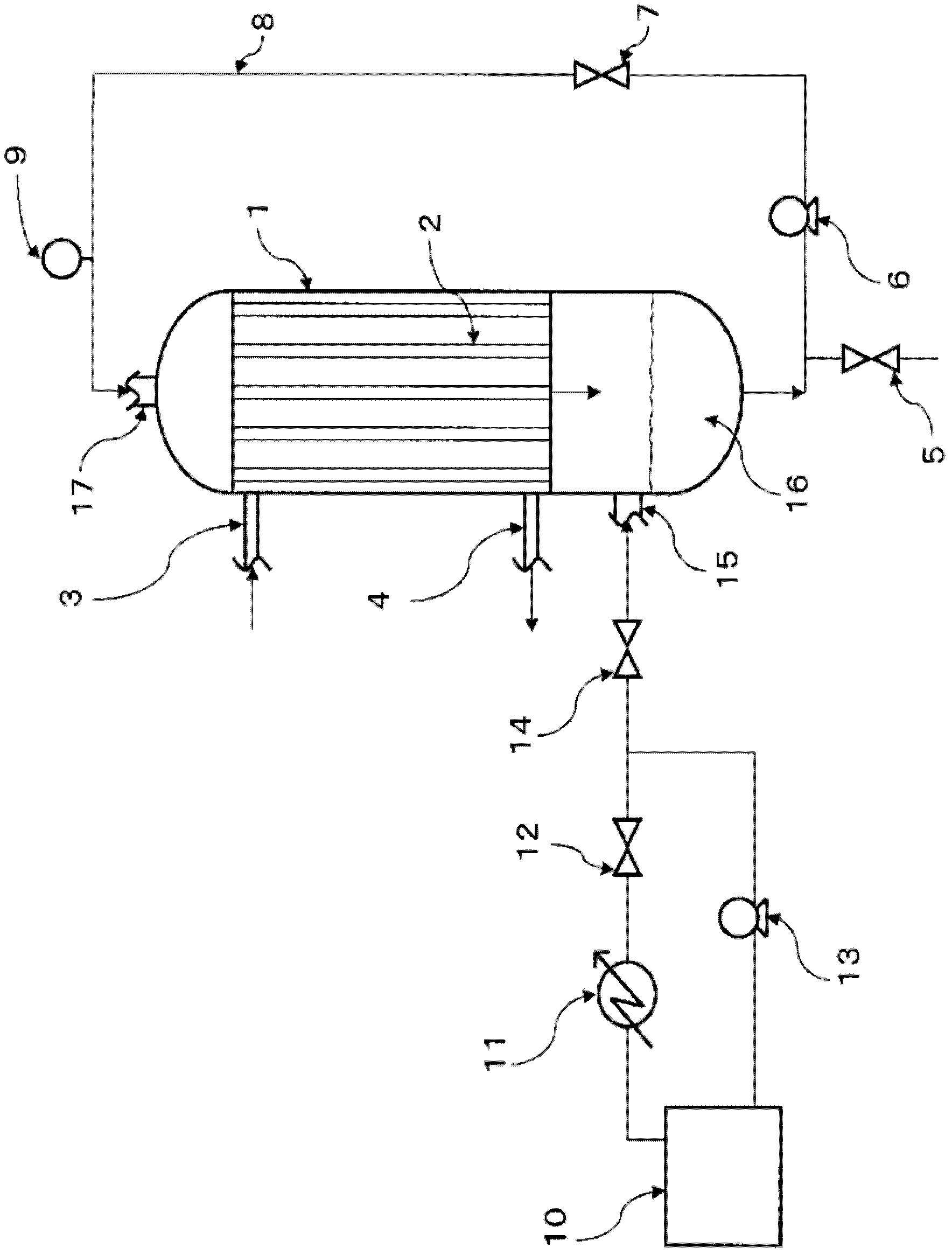

Device and method for crystallizing (meth)acrylic acid

A crystallization device, acrylic acid technology, applied in solution crystallization, heat exchange cooling crystallization, crystallization adjustment/control, etc., can solve the problem that the blockage of the heat exchanger cannot be suppressed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Preparation of crude acrylic acid solution

[0056] Propylene was supplied to the gas-phase catalytic oxidation reaction in the reactor, and the obtained reaction gas was introduced into the absorption tower and brought into contact with the absorption liquid, and a crude acrylic acid solution was obtained at the bottom of the absorption tower. Analysis of the obtained crude acrylic acid solution revealed that it contained: 90.0% by mass of acrylic acid, 3.2% by mass of water, 1.9% by mass of acetic acid, 0.6% by mass of maleic acid, 1.5% by mass of acrylic acid dimer, 0.07% by mass of furfural, 0.27% by mass of benzaldehyde, 0.06% by mass of formaldehyde, 0.1% by mass of hydroquinone, and 2.3% by mass of other impurities. In addition, the temperature of the bottom liquid of the absorption tower at this time, that is, the temperature of the crude acrylic acid solution immediately discharged from the absorption tower was 91°C. The resulting crude acrylic acid was us...

Embodiment 2

[0070] Acrylic acid was produced in the same manner as in Example 1 above, except that the pressure of the circulation supply pipe 8 was maintained in the range of 0.10 MPa to 0.16 MPa in the crystallization process. At this time, the difference between the maximum value and the minimum value of the measured pressure value was 0.06 MPa within 100% of the minimum value.

[0071] Analysis of the obtained purified acrylic acid showed that the purity of acrylic acid was 99.89% by mass, and in addition, it contained 153 mass ppm of water, 710 mass ppm of acetic acid, 4 mass ppm of maleic acid, and 100 mass ppm of acrylic acid dimer , furfural 0.5 mass ppm, benzaldehyde 0.4 mass ppm, no formaldehyde was detected. In addition, the production efficiency after the above process is 9.98kg / hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com