Fluid for removing coating film formed by csd, method for removing csd coating film using same, and ferroelectric thin film and process for producing same

A manufacturing method and coating film technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of easy cracks in the film and the decline of equipment qualification rate, so as to prevent pollution, prevent the formation of sediment, The effect of low penetrating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

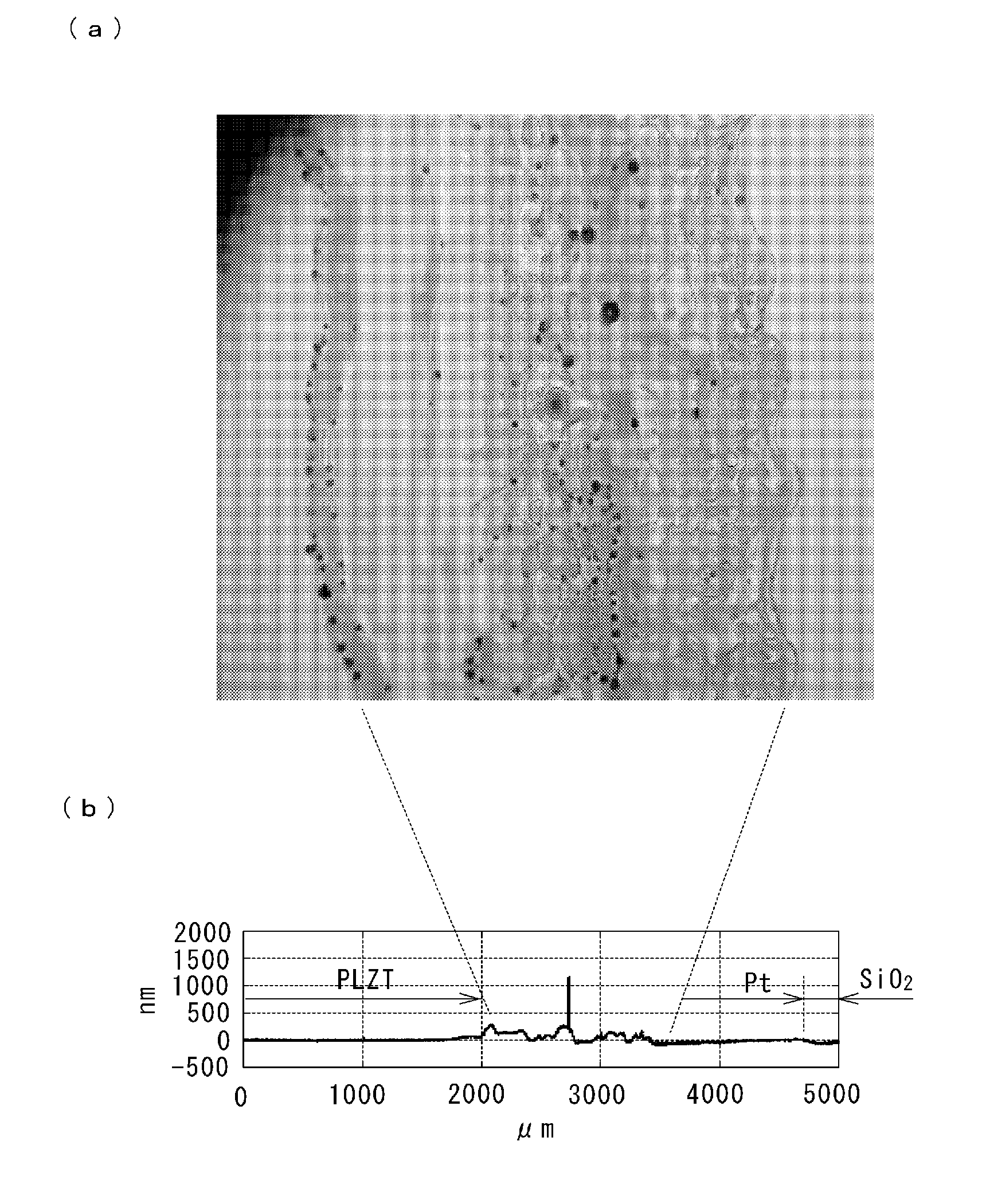

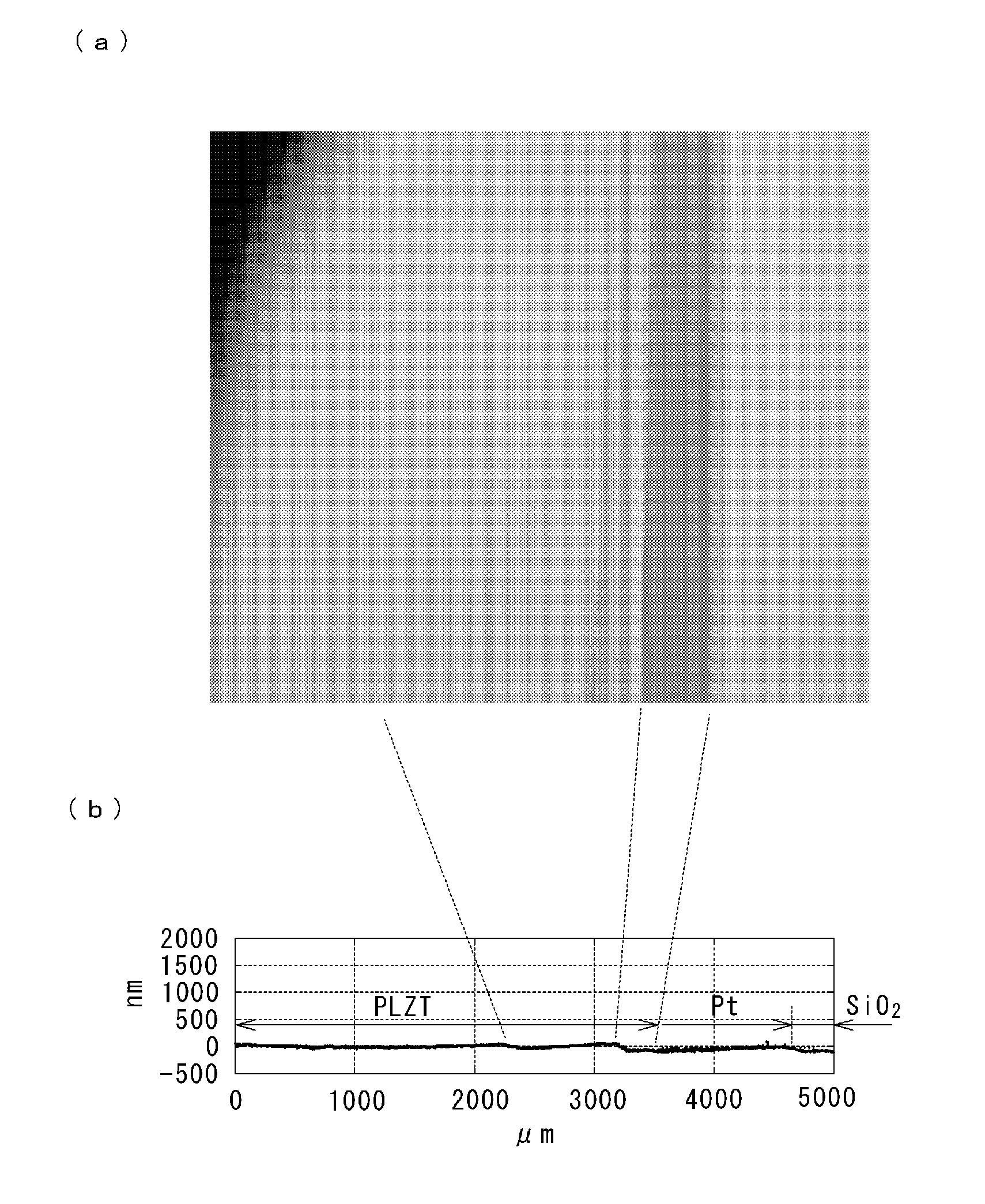

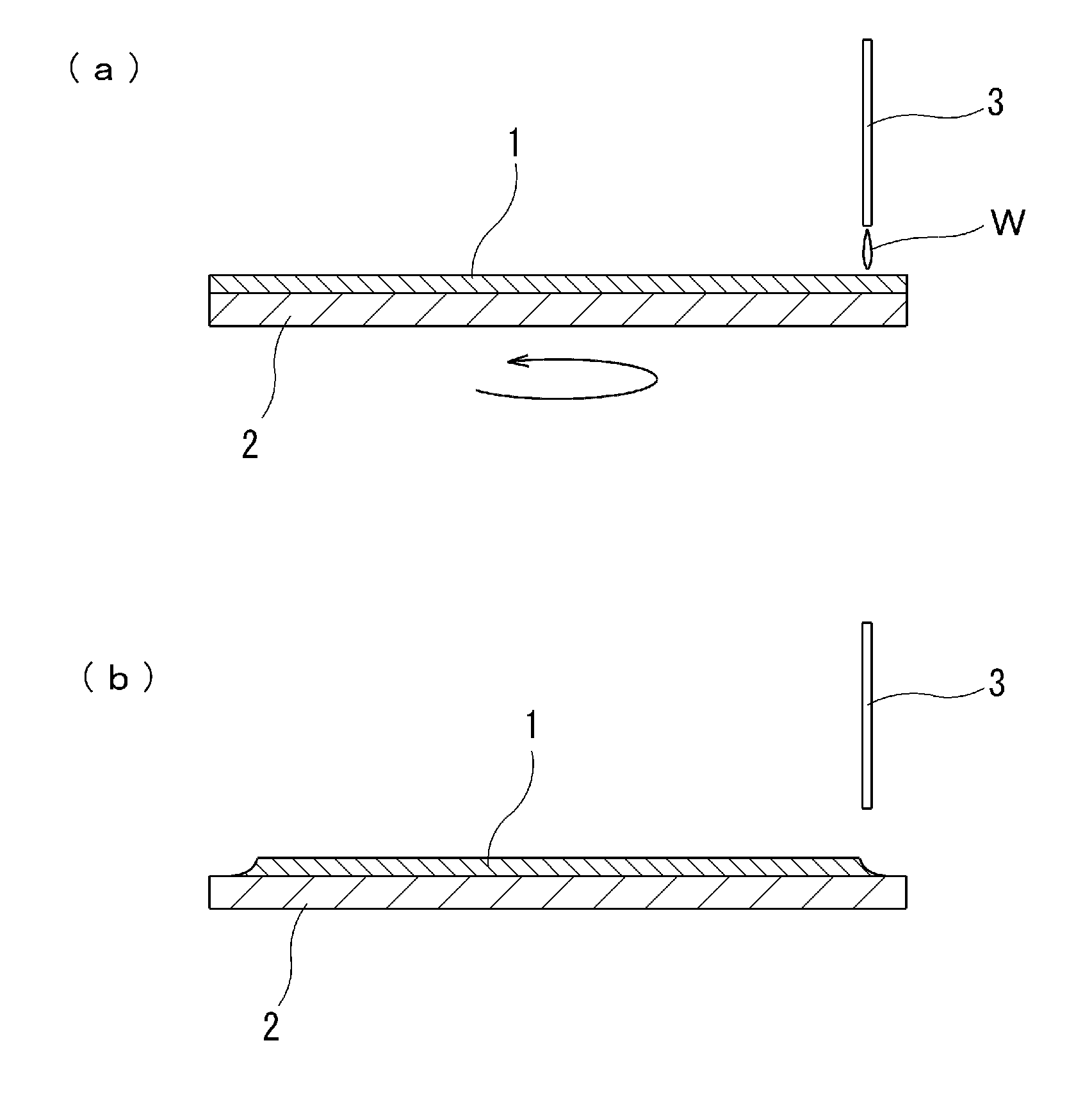

[0091] Next, as Example 1, in the same Pt / SiO 2 / Si substrate is the same as the method of the above-mentioned preliminary experiment. After spin-coating 10wt% raw material solutions 1-1~1-6, in order to avoid the Pb-containing film and SiO 2 In the reaction during firing, while the substrate is rotated at 2500 rpm with a spin coater, liquids 1 to 62 for removal are sprayed at positions 5 mm inward in the radial direction from the outer peripheral edge of the substrate to dissolve the gel-like coating film. EBR processing. The liquids 1 to 62 for removal contained an organic solvent and water at a predetermined weight ratio as shown in Table 5 and Table 6. Among them, the removal liquids 1 to 50 contain one type of organic solvent X and water, and the removal liquids 51 to 61 contain an organic solvent in which two types of organic solvents X and Y are mixed in a predetermined weight ratio, and water. The liquid 62 for removal is water and does not contain an organic solvent...

Embodiment 2)

[0103] As Example 2, the situation of the layered perovskite oxide film containing Bi is the same as that of the perovskite oxide film containing Pb (Example 1), and the 10wt% raw material solution 2-1 of Table 2 ~2-6 spin-coated on 4 inch Pt / SiO 2 / Si substrate, in order to avoid cracks caused by the thicker film at the outer peripheral end of the substrate, while using a spin coater to rotate the substrate at 2500rpm, each of the removal liquids 1 to 62 shown in Table 5 and Table 6 was sprayed on the At a position 5 mm inward in the radial direction from the outer peripheral end of the substrate, the gel-like coating film was dissolved and EBR treatment was performed. This substrate was heated on a hot plate in the same manner as in the case of the Pb-containing perovskite-type oxide thin film to obtain a Bi-containing oxide thin film in a state where the outer peripheral end portion was etched. As in the case of the Pb-containing perovskite-type oxide thin film, this opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com