Ag/MnyOx/C catalyst and preparation and application thereof

A technology of catalysts and mixtures, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst supports, etc., can solve the problem of unsatisfactory catalytic activity, stability and discharge limit current density at the same time Problems, to achieve the effect of environmental protection, speed up the process of industrialization, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] First, 1g KMnO 4 Add to 20mL boiling water, gradually add 1.075g AgNO under stirring condition 3 Crystal, KMnO 4 and AgNO 3 The molar ratio is 1:1. Naturally cooled to room temperature, and then cooled to 2°C with an ice-water bath to obtain needle-shaped purple crystals and a purple solution. Filter and wash the solid matter with 200 mL of 2 °C ice water to remove residual K + and NO 3 - ; Naturally air-dried to obtain purple crystal AgMnO 4 .

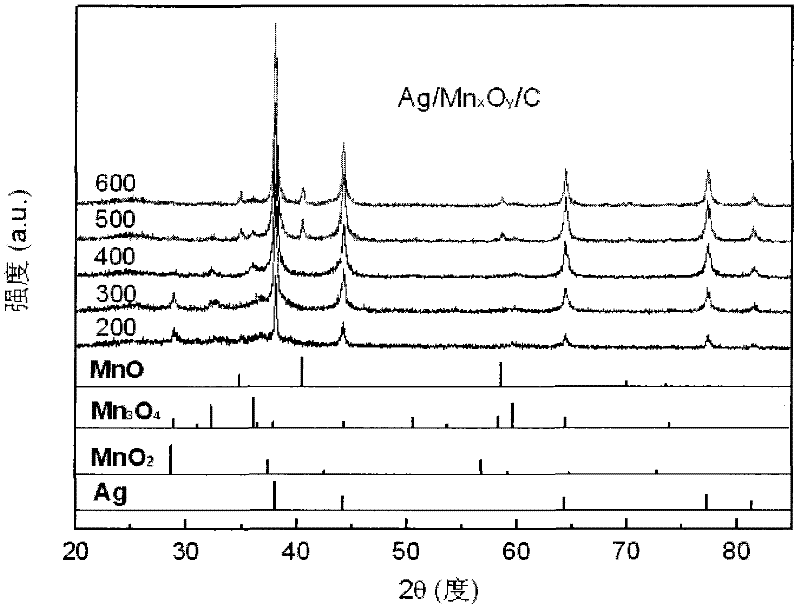

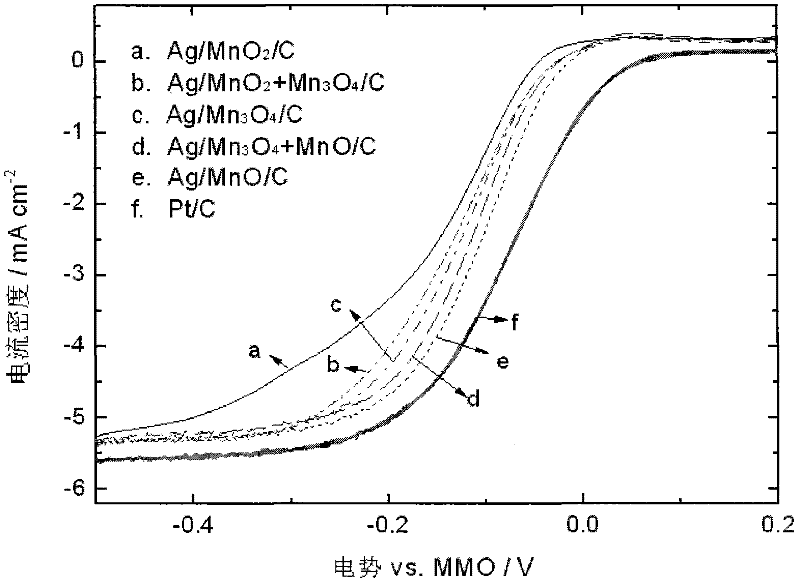

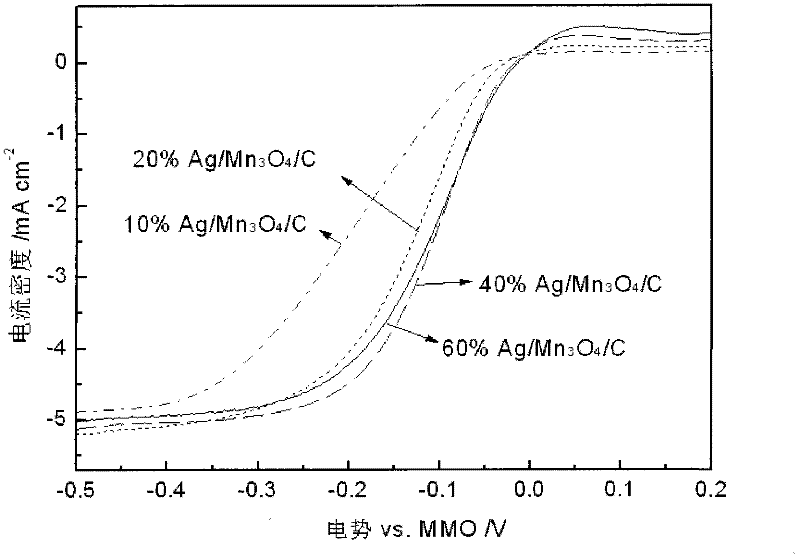

[0046] The prepared 46.6mg AgMnO 4 Dissolve in 50mL of deionized water, add 60mg of Vulcan XC-72R carbon black, disperse evenly by ultrasonication for 30min, impregnate and stir for 4h at room temperature, then place in a water bath at 50°C and evaporate to dryness to obtain black powder AgMnO 4 / C. The resulting black powder AgMnO 4 / C ground, weighed and placed in a quartz boat, then transferred to a tube furnace and 2 Under atmosphere at 5°C min -1 The temperature was programmed to rise to 200°C, and treated at ...

Embodiment 2

[0048] First, 1g KMnO 4 Add to 20mL boiling water, gradually add 1.075g AgNO under stirring condition 3 Crystal, KMnO 4 and AgNO 3 The molar ratio is 1:1. Naturally cooled to room temperature, and then cooled in an ice-water bath to obtain needle-shaped purple crystals and a purple solution. Filter and wash with 200 mL of 2°C ice water to remove residual K + and NO 3 - ; Naturally air-dried to obtain purple crystal AgMnO 4 .

[0049] The prepared 46.6mg AgMnO 4 Dissolve in 50mL deionized water, then add 60mg Vulcan XC-72R carbon black, disperse evenly by ultrasonication for 30min, impregnate and stir at room temperature for 4h, then place in a water bath at 50°C and evaporate the water to dryness to obtain black powder AgMnO 4 / C. The resulting black powder AgMnO 4 / C ground, weighed and placed in a quartz boat, then transferred to a tube furnace and 2 Under atmosphere at 5°C min -1 The temperature was programmed to rise to 300°C, and treated at this temperature f...

Embodiment 3

[0051] First, 1g KMnO 4 Add to 20mL boiling water, gradually add 1.075g AgNO under stirring condition 3 Crystal, KMnO 4 and AgNO 3 The molar ratio is 1:1. Naturally cooled to room temperature, and then cooled in an ice-water bath to obtain needle-shaped purple crystals and a purple solution. Filter and wash with 200 mL of 2°C ice water to remove residual K + and NO 3 - ; Naturally air-dried to obtain purple crystal AgMnO 4 .

[0052] The prepared 46.6mg AgMnO 4 Dissolve in 50mL deionized water, then add 60mg Vulcan XC-72R carbon black, disperse evenly by ultrasonication for 30min, impregnate and stir at room temperature for 4h, then place in a water bath at 50°C and evaporate the water to dryness to obtain black powder AgMnO 4 / C. The resulting black powder AgMnO 4 / C ground, weighed and placed in a quartz boat, then transferred to a tube furnace and 2 Under atmosphere at 5°C min -1 The temperature was programmed to rise to 400°C, and treated at this temperature f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com