SOI/III-V full wafer bonding method adopting three-dimensional vent-hole device

A III-V, wafer bonding technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of dense bubbles at the interface, difficult to discharge gas, etc., to improve bonding strength, reduce material consumption, Density reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

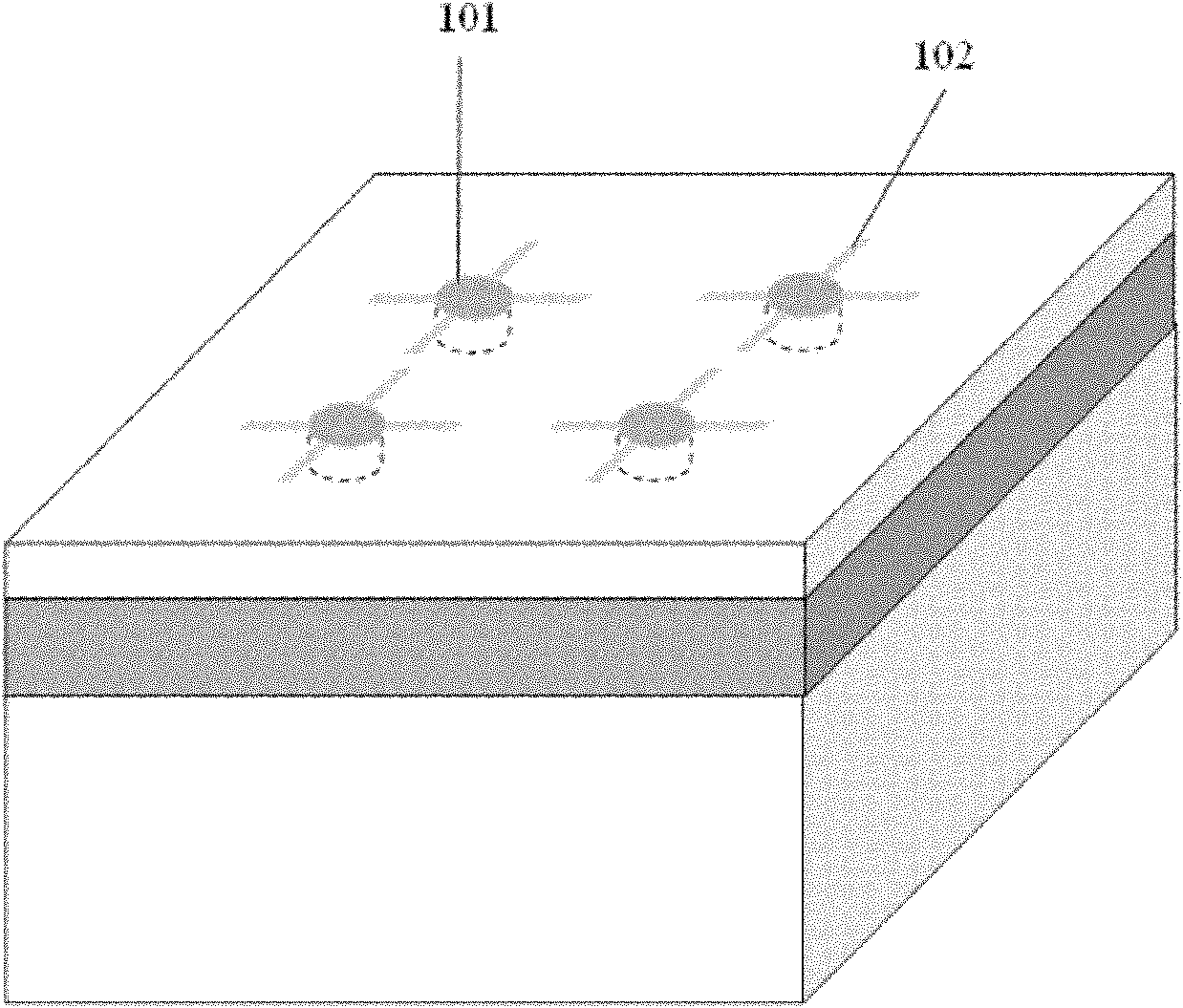

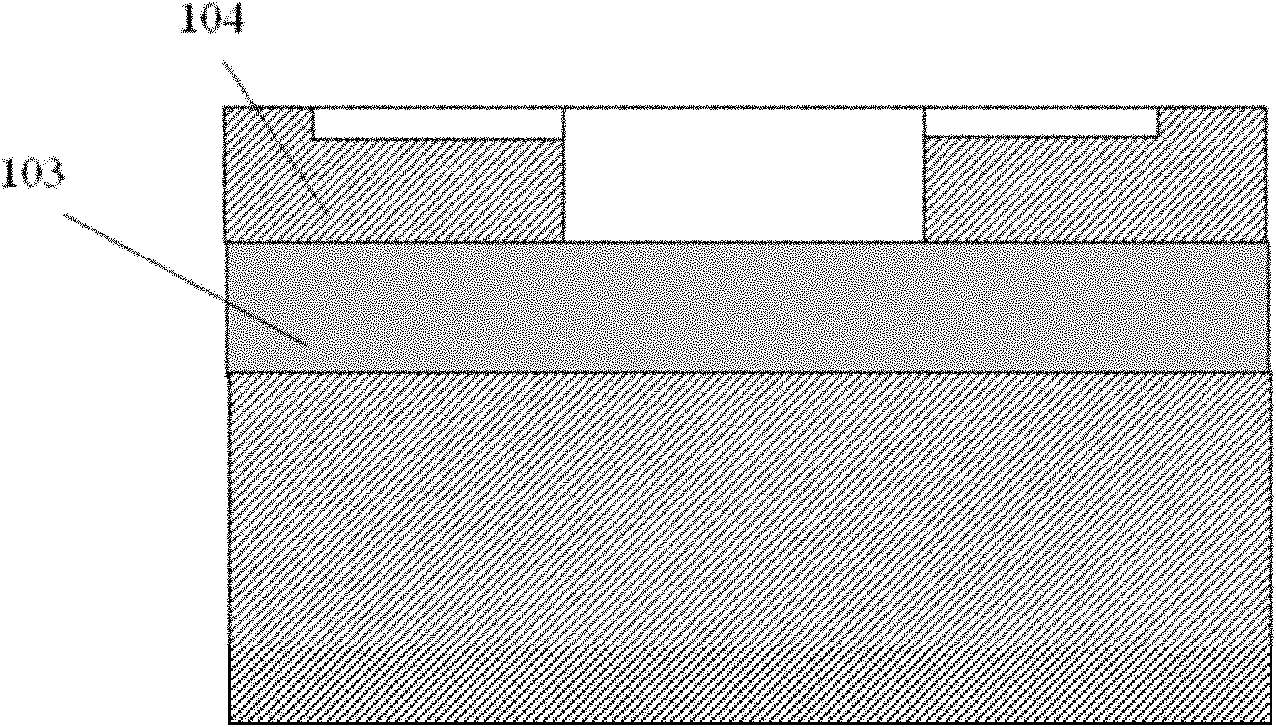

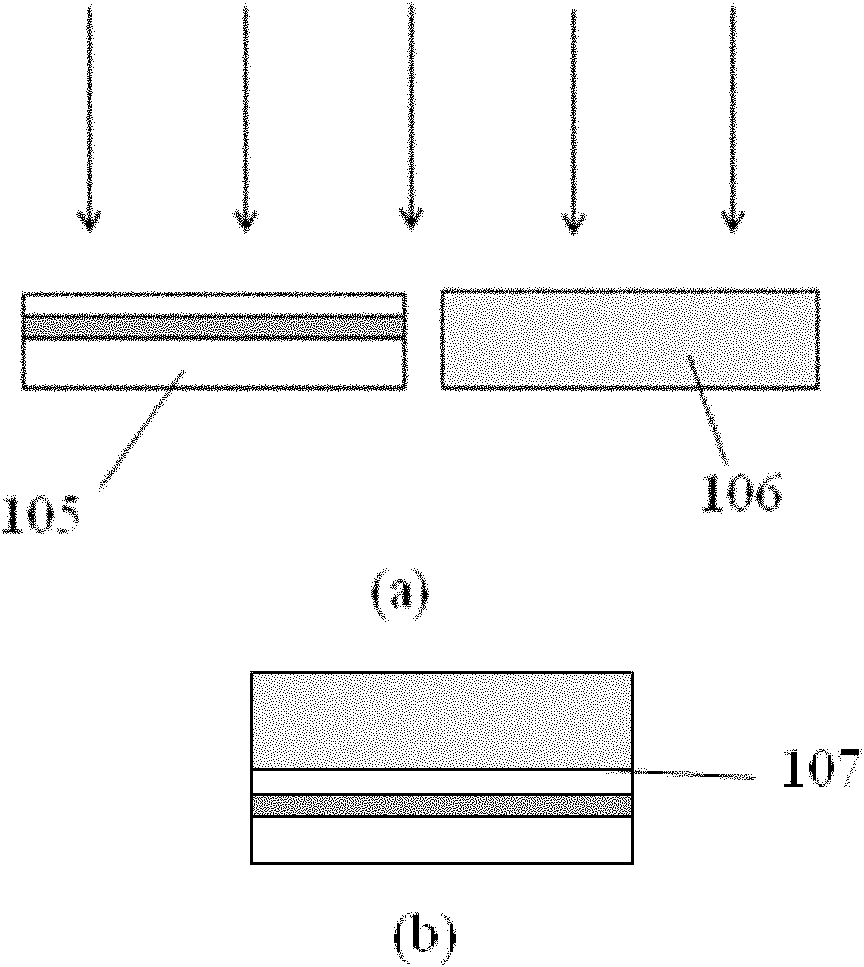

[0029] The embodiment of the present invention proposes a SOI / III-V whole wafer bonding technology using a three-dimensional vent device, figure 1 Shown is an appearance rendering of an SOI substrate with a three-dimensional vent structure, which includes vertical vent holes 103 and horizontal vent slots 104 . The exhaust hole is circular, and the aperture can be adjusted according to specific needs. The exhaust hole passes through the top Si layer of the SOI substrate to the BOX layer. The distance between the exhaust holes can be adjusted according to the specific application. It acts as a vertical exhaust channels that allow the H generated during the bonding process to 2 O and H 2 The gas is absorbed and diffused th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com